10 Steps to Becoming a Kitchen Fabricator: A Full Guide

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Becoming a kitchen fabricator is a rewarding journey for those interested in working with their hands, being creative, and transforming kitchen spaces with high-quality materials. Whether you’re considering this career path or looking to enhance your skills, this guide provides a straightforward approach to becoming a successful kitchen fabricator.

1. Understand the Role of a Kitchen Fabricator

Before diving in, it's essential to know what a kitchen fabricator does. Fabricators cut, shape, and install materials such as granite, quartz, and wood for countertops and cabinets. They must be precise, detail-oriented, and skilled with tools to create seamless designs that enhance a kitchen’s look and functionality.

2. Gain Basic Knowledge in Carpentry or Stonework

Starting with a foundation in carpentry, stonework, or cabinet making is helpful. This experience gives you hands-on skills with the materials and tools common in kitchen fabrication. If you’re a beginner, consider taking courses in woodworking or masonry to familiarize yourself with the basics.

3. Complete Relevant Education or Training

Although formal education isn’t always required, completing a vocational course in construction, design, or woodworking can be very beneficial. Many community colleges and trade schools offer certifications in construction or fabrication, providing you with the knowledge you need to start your career confidently.

4. Get Hands-On Training Through an Apprenticeship

On-the-job experience is crucial in this field. Look for apprenticeships or internships with experienced kitchen fabricators. Apprenticeships allow you to learn directly from professionals, picking up tips and techniques that textbooks can’t teach. Many employers prefer candidates with real-world experience, so this step is vital for your growth.

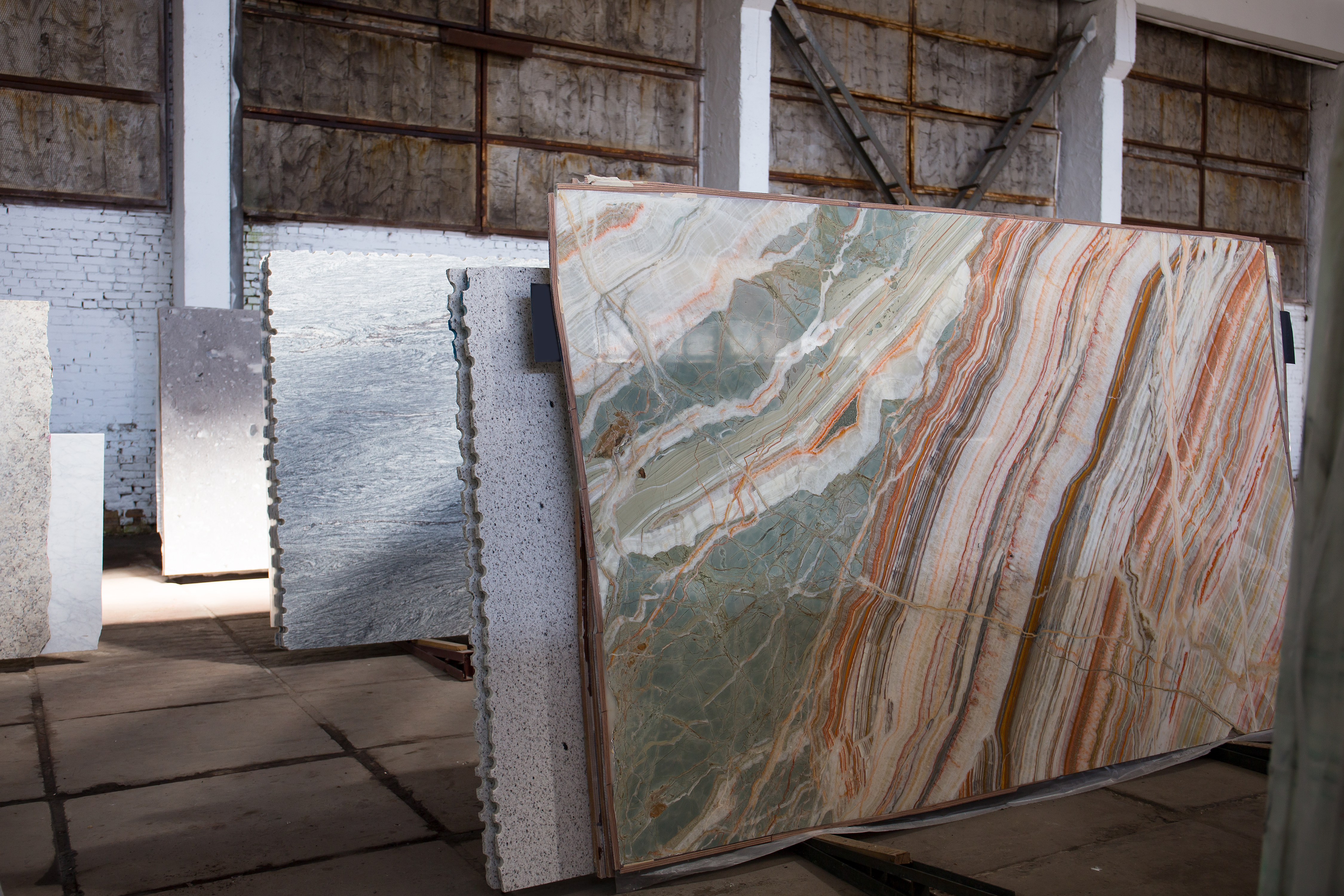

5. Learn to Work with Various Materials

As a kitchen fabricator, you’ll work with a range of materials, from granite and marble to wood and stainless steel. Each material has unique properties, requiring different tools and techniques. By learning to handle multiple materials, you’ll be more versatile, which can make you more attractive to potential clients or employers.

6. Develop Strong Attention to Detail

Precision is key in kitchen fabrication. Even a small mistake can lead to costly reworks or dissatisfied clients. Practicing patience and developing a keen eye for detail will ensure you create high-quality pieces every time. Take your time when measuring, cutting, and finishing to achieve excellent results.

7. Master Essential Tools and Equipment

Fabrication requires various tools, from handheld devices like sanders and grinders to larger machines such as CNC routers. Becoming proficient with these tools is essential. If you’re new, start by learning the basics, then gradually build your tool-handling skills. Practicing under supervision is a great way to gain confidence.

8. Get Certified for Safety and Professional Standards

In some regions, certifications in safety and handling specific materials are necessary. For example, working with quartz or granite often requires knowing dust control and protective measures. Consider taking OSHA (Occupational Safety and Health Administration) courses or other relevant certifications to ensure you’re following industry standards.

9. Build a Portfolio

A solid portfolio showcasing your work will make a huge difference when looking for jobs or clients. Include photos of completed projects, along with details about materials used, design elements, and client requirements. If you’re just starting, you could take on small projects for family and friends to build your initial portfolio.

10. Network with Industry Professionals

Connecting with other professionals in the kitchen fabrication industry can open doors to job opportunities and mentorship. Join industry associations, attend trade shows, and participate in workshops. Networking not only helps you stay updated on industry trends but also connects you with people who can support your career growth.

Expanding Your Skills and Growing Your Career

As you build your foundation in kitchen fabrication, remember that learning never truly stops. This field constantly evolves, with new materials, techniques, and design trends emerging regularly. Here are some ways to continue growing:

Stay Updated on Industry Trends

Styles and preferences in kitchen design change over time. Stay informed about popular materials, design trends, and innovative techniques. Subscribe to industry magazines, follow relevant social media accounts, and attend trade shows to keep your knowledge fresh. Clients appreciate fabricators who can offer insights on current trends.

Invest in Advanced Tools and Technology

Technology plays a significant role in fabrication, with tools like CNC (Computer Numerical Control) machines offering precise, automated cuts. Investing in advanced tools can increase the quality of your work and improve efficiency. While these tools may be costly, they’re a worthwhile investment as your business or expertise grows.

Expand Your Services

Kitchen fabrication often involves collaborating with other trades, such as plumbers, electricians, and general contractors. Expanding your knowledge in these areas can make you more versatile. Some fabricators even branch out to offer additional services like countertop installation or custom cabinetry, adding more value for clients.

Consider Specializing in High-Demand Areas

Specializing can set you apart in a competitive market. For instance, you could focus on eco-friendly materials, unique stonework, or ultra-modern kitchen designs. Specializations allow you to build expertise and attract clients looking for specific, skilled work.

Build Strong Client Relationships

Success in this field is often driven by word of mouth. Providing excellent customer service, completing projects on time, and communicating well with clients can help you build a positive reputation. Many fabricators gain repeat business and referrals simply by making the client experience smooth and enjoyable.

Tips for New Kitchen Fabricators

Starting out can feel overwhelming, but here are a few tips to ease the journey:

Start Small: It’s okay to begin with small projects or assistant roles. Use these as learning opportunities.

Ask Questions: Don’t hesitate to ask questions when working with experienced fabricators. This can speed up your learning process and help you avoid common mistakes.

Practice Patience: Fabrication requires precision, so take your time to get things right. This will help you build a reputation for quality.

Embrace Mistakes as Learning Opportunities: Mistakes happen, especially in a hands-on field like fabrication. Learn from them, and use each error as a chance to improve.

Final Thoughts

Becoming a kitchen fabricator isn’t just about learning the technical skills – it’s also about gaining hands-on experience, building connections, and continuously improving. Following these ten steps will put you on the path to becoming a trusted and skilled professional in this field. With dedication, practice, and a commitment to quality, you can craft beautiful kitchens and enjoy a fulfilling career as a kitchen fabricator.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.