3D Metrology Market Size, Share and Trends Forecast 2025-2033

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Market Overview:

The 3D Metrology Market is experiencing rapid growth, driven by Rising Demand for Precision in Manufacturing, Advancements in Measurement Technologies, and Growing Adoption in Automotive and Aerospace Industries. According to IMARC Group's latest research publication, "3D Metrology Market Report by Offering (Hardware, Software, Services), Product (Coordinate Measuring Machine (CMM), Optical Digitizer & Scanner (ODS), Video Measuring Machine (VMM), 3D Automated Optical Inspection System (AoI), Form Measurement), Application (Quality Control & Inspection, Reverse Engineering, Virtual Simulation, and Others), End-Use Industry (Aerospace & Defense, Automotive, Architecture & Construction, Medical, Electronics, Energy & Power, Heavy Industry, Mining, and Others), and Region 2025-2033", the global 3D metrology market size reached USD 11.0 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 21.1 Billion by 2033, exhibiting a growth rate (CAGR) of 7.5% during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Download a sample PDF of this report: https://www.imarcgroup.com/3d-metrology-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends and Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Growth Factors in the 3D Metrology Market:

- Rising Demand for Precision in Manufacturing

The global manufacturing landscape is evolving rapidly, with increased emphasis on miniaturization, complex geometries, and zero-defect tolerances. In industries such as aerospace, medical devices, automotive, and semiconductors, the margin for error is virtually nonexistent. Even a few microns of deviation can compromise performance, safety, or compliance. 3D metrology plays a crucial role in maintaining precision across every production stage—from prototyping and tooling to final assembly. Tools such as coordinate measuring machines (CMM), laser scanners, and optical digitizers are now standard in quality assurance operations. Furthermore, real-time metrology integration in production lines enables dynamic adjustments, reducing downtime and material wastage.

- Advancements in Measurement Technologies

Technological innovation is redefining the capabilities of 3D metrology systems. The shift from manual inspection to non-contact, high-speed scanning methods—like structured light and laser triangulation—has made measurement processes faster, more accurate, and less invasive. Multi-sensor platforms now combine tactile and optical probes to capture intricate surface geometries and complex contours in a single scan. Meanwhile, artificial intelligence and machine learning algorithms are being used to enhance error detection, automate report generation, and forecast quality anomalies. Adaptive algorithms allow systems to self-correct and optimize scan parameters based on real-time feedback. Additionally, integration with CAD/CAM systems allows for instant comparison between design models and real-world objects, speeding up the first-article inspection process.

- Growing Adoption in Automotive and Aerospace Industries

The adoption of 3D metrology tools in the automotive and aerospace sectors has grown from a quality control measure to a mission-critical process integrated across the product lifecycle. In automotive manufacturing, metrology is essential for stamping die validation, gap and flush inspection, EV battery pack verification, and lightweight material integration. As the shift toward electric and autonomous vehicles accelerates, the need for ultra-precise components becomes even more pronounced. In aerospace, the complexity and regulatory scrutiny of parts like jet engines, fuselage panels, and satellite components demand micron-level accuracy. Additive manufacturing, now widely used in both industries, further necessitates advanced metrology to verify surface finish, layer consistency, and structural integrity. Digital twin technology is gaining traction, allowing companies to simulate, monitor, and refine products virtually.

Key Trends in the 3D Metrology Market:

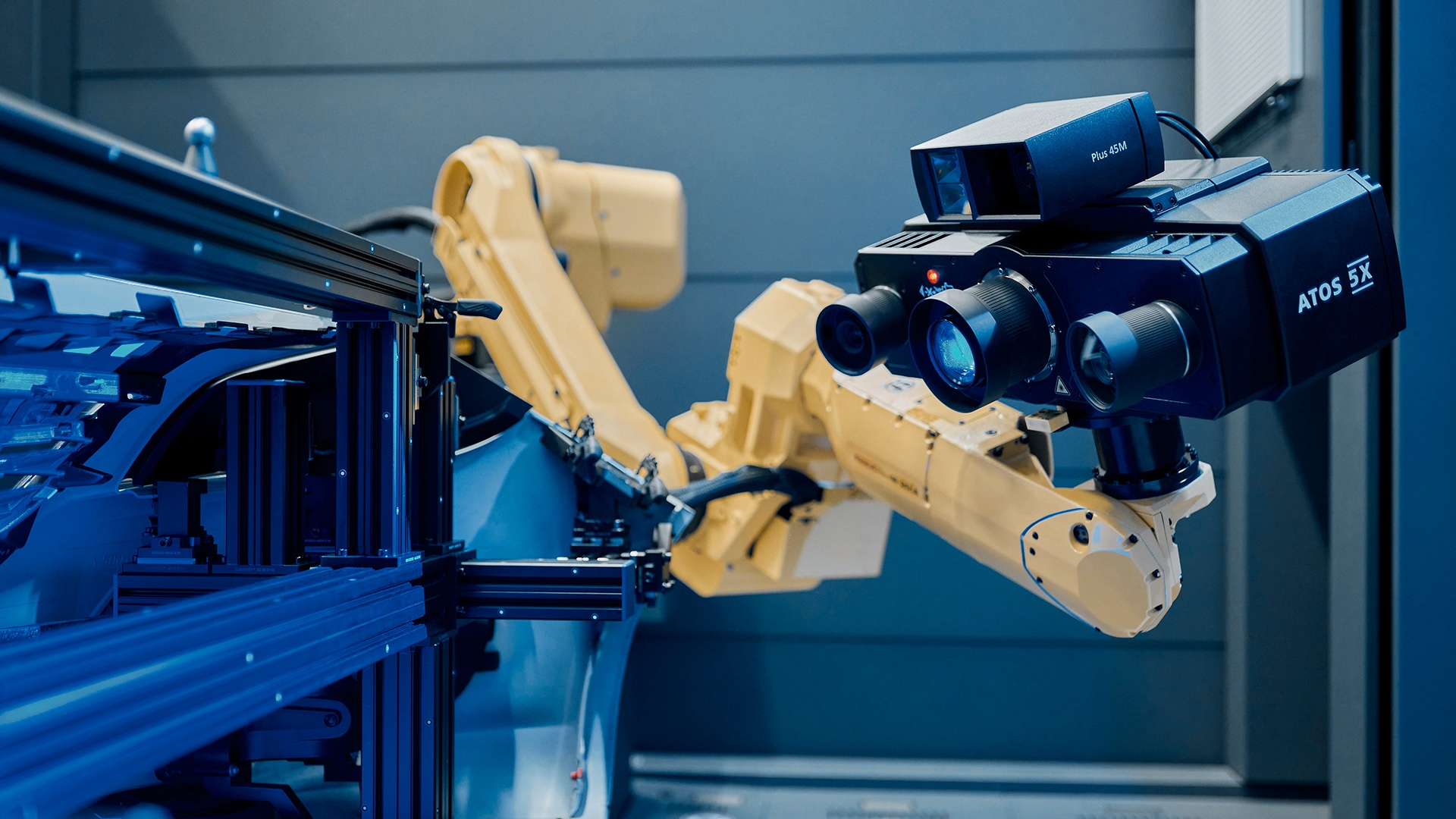

- Integration of Automation and Robotics

The integration of 3D metrology systems with robotics and automation is revolutionizing quality assurance. Automated robotic inspection cells equipped with 3D scanners or CMM arms can now conduct continuous, inline inspections without halting production. This is especially critical in high-volume environments like automotive assembly lines, where any delay can lead to cascading losses. These systems can dynamically adjust to part changes and identify defects early in the process, reducing scrap rates and costly rework. The deployment of collaborative robots (cobots) further enhances flexibility, enabling shared workspaces where humans and robots perform inspections together.

- Cloud-Based Data Analytics and Remote Monitoring

Cloud computing is transforming 3D metrology from a localized process into a networked ecosystem of quality intelligence. Cloud-connected metrology systems allow real-time synchronization of inspection data across multiple manufacturing sites, making enterprise-wide quality management feasible and efficient. Data can be accessed securely by stakeholders, suppliers, and R&D teams regardless of location. Advanced analytics platforms are leveraging machine learning to identify patterns and anomalies, optimize measurement strategies, and forecast equipment maintenance needs before downtime occurs. Cloud platforms also enable version control, historical traceability, and automated compliance documentation, streamlining audits and certifications.

- Expansion into New Industries and Use Cases

3D metrology’s application is no longer confined to heavy industrial manufacturing; it’s gaining momentum across a diverse set of fields. In the medical sector, it enables the creation of patient-specific implants, surgical tools, and orthodontic devices through precise anatomical scanning. In construction and civil engineering, 3D laser scanning is used for structural health monitoring, building renovation, and verifying as-built conditions against digital plans. Cultural preservation projects are leveraging 3D scanning to digitally archive historical monuments and delicate artifacts. Even in sports equipment design, metrology helps optimize aerodynamic performance and ergonomic fit. In mining and energy, metrology supports wear analysis, reverse engineering, and safety inspections of high-value machinery.

Leading Companies Operating in the Global 3D Metrology Industry:

- 3d Digital Corporation

- Automated Precision Inc.

- Carl Zeiss AG

- Creaform Inc.

- FARO Technologies, Inc.

- GOM GmbH

- Hexagon AB

- Jenoptik AG

- KLA Corporation

- Mitutoyo Corporation

- Nikon Metrology NV

- Perceptron, Inc.

- Renishaw PLC

3D Metrology Market Report Segmentation:

By Offering:

- Hardware

- Software

- Services

By Product:

- Coordinate Measuring Machine (CMM)

- Optical Digitizer & Scanner (ODS)

- Video Measuring Machine (VMM)

- 3D Automated Optical Inspection System (AoI)

- Form Measurement

By Application:

- Quality Control & Inspection

- Reverse Engineering

- Virtual Simulation

- Others

By End-Use Industry:

- Aerospace & Defense

- Automotive

- Architecture & Construction

- Medical

- Electronics

- Energy & Power

- Heavy Industry

- Mining

- Others

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

North America dominates the 3D metrology market due to its well-established manufacturing sector, strong investments in automation, and widespread adoption of Industry 4.0 technologies.

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.