3D Printing in Healthcare Market Trends, Growth Rate and Forecast 2024-2032

Global 3D Printing in Healthcare Market: Key Statistics and Insights in 2024-2032

Summary:

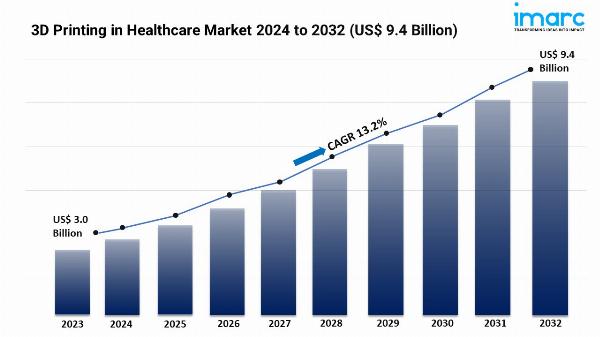

- The global 3d printing in healthcare market size reached USD 3.0 Billion in 2023.

- The market is expected to reach USD 9.4 Billion by 2032, exhibiting a growth rate (CAGR) of 13.2% during 2024-2032.

- North America leads the market, accounting for the largest 3d printing in healthcare market share.

- Polymer represents the largest segment due to their versatility, biocompatibility, and cost-effectiveness in producing customized medical devices and implants.

- Droplet deposition (fused filament fabrication (FFF) technology, low-temperature deposition manufacturing (LDM), and multiface jet solidification (MJS)) holds the biggest market share as it is widely used for its precision and ability to create intricate, patient-specific models and prosthetics.

- The growing demand for personalized and patient-specific medical devices, a trend strongly supported by advancements in 3D printing technology, is offering a favorable market outlook.

- Bioprinting, a subset of 3D printing that involves the layer-by-layer construction of biological tissues, is propelling the market growth.

Industry Trends and Drivers:

- Increasing Demand for Customized Medical Devices:

The growing demand for personalized and patient-specific medical devices, a trend strongly supported by advancements in 3D printing technology, is offering a favorable market outlook. This technology enables for the creation of highly customized prosthetics, implants, and surgical instruments tailored to the unique anatomical needs of individual patients. Such customization enhances patient outcomes by improving the fit, comfort, and functionality of medical devices. Additionally, 3D printing enables rapid prototyping and iteration, allowing healthcare providers to refine designs quickly and efficiently. This level of customization is particularly crucial in complex surgeries where standard devices may not suffice, further driving the adoption of 3D printing in healthcare.

● Advancements in Bioprinting Technologies:

Bioprinting, a subset of 3D printing that involves the layer-by-layer construction of biological tissues, is propelling the market growth. Advancements in this technology are paving the way for creating complex tissue structures, such as skin, cartilage, and even organ models, which have profound implications for regenerative medicine, drug testing, and transplantation. Researchers are increasingly exploring the potential of bioprinting to address the limited availability of donor organs by developing viable, patient-specific tissues and organs. This technology also supports the creation of highly accurate disease models, enabling better understanding and treatment of various conditions.

● Reduction in Production Costs and Time:

3D printing technology is significantly reducing the time and cost associated with producing medical devices and components. Traditional manufacturing processes often involve lengthy and expensive tooling and setup phases, particularly for small production runs or custom items. In contrast, 3D printing allows for direct digital manufacturing, where complex geometries can be produced quickly without the need for specialized tooling. This efficiency not only lowers production costs but also reduces lead times, enabling faster delivery of medical solutions. For healthcare providers, this means more timely and cost-effective access to critical devices, such as implants and surgical tools, improving patient care and operational efficiency.

Request for a sample copy of this report: https://www.imarcgroup.com/3d-printing-in-healthcare-market/requestsample

3D Printing in Healthcare Market Report Segmentation:

By Material:

- Polymer

- Metals

- Ceramic

- Organic

Polymer represents the largest segment due to their versatility, biocompatibility, and cost-effectiveness in producing customized medical devices and implants.

By Technology:

- Droplet Deposition

- Fused Filament Fabrication (FFF) Technology

- Low-temperature Deposition Manufacturing (LDM)

- Multiphase Jet Solidification (MJS)

- Photopolymerization

- Stereolithography (SLA)

- Continuous Liquid Interface Production (CLIP)

- Two-photon Polymerization (2PP)

- Laser Beam Melting

- Selective Laser Sintering (SLS)

- Selective Laser Melting (SLM)

- Direct Metal Laser Sintering (DMLS)

- Electronic Beam Melting (EBM)

- Laminated Object Manufacturing

- Others

Droplet deposition (fused filament fabrication (FFF) technology, low-temperature deposition manufacturing (LDM), and multiface jet solidification (MJS)) holds the biggest market share as it is widely used for its precision and ability to create intricate, patient-specific models and prosthetics.

By Application:

- External Wearable Devices

- Hearing Aids

- Prosthesis and Orthotics

- Dental Products

- Clinical Study Devices

- Drug Testing

- Anatomical Models

- Implants

- Surgical Guides

- Cranio-maxillofacial Implants

- Orthopedic Implants

- Tissue Engineering

External wearable devices (hearing aids, prosthetics and orthotics, and dental products) represent the leading segment owing to the ability of 3D printing to produce highly personalized and comfortable products tailored to individual patient needs.

By End User:

- Medical and Surgical Centers

- Pharmaceutical and Biotechnology Companies

- Academic Institutions

Medical and surgical centers account for the majority of the market share because these are the primary healthcare facilities using 3D printing extensively for custom implants, surgical guides, and anatomical models.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

North America’s dominance in the 3D printing in healthcare market is attributed to its advanced healthcare infrastructure, significant investment in medical technology, and early adoption of 3D printing innovations.

Top 3D Printing in Healthcare Market Leaders: The 3d printing in healthcare market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies. Some of the key players in the market are:

- 3D Systems Inc.

- Desktop Metal Inc.

- EOS GmbH

- Formlabs

- Materialise NV

- Organovo Holding Inc.

- Oxford Performance Materials Inc.

- Prodways Tech

- Proto Labs Inc.

- Renishaw plc

- SLM Solutions Group AG

- Stratasys Ltd

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.