4-Axis Machining: Unleashing Precision and Complexity in Manufacturing

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

4-axis machining is a so manufacturing process that offers enhanced capabilities compared to traditional 3-axis machining. It involves the use of a computer numerical control CNC machine with four axes of movement – the X, Y, and Z axes like in 3-axis machining, plus an additional rotational axis. In this article, we will explore the world of 4-axis machining, including its definition, process, types of machines, applications, benefits, and phisticated disadvantages.

The Process of 4-Axis CNC Machining

The process of 4-axis CNC machining is similar to that of 3-axis machining, but with the added complexity of the rotational axis. The process typically begins with the design of the part using computer-aided design (CAD) software. The CAD model is then converted into machine-readable code using computer-aided manufacturing (CAM) software.

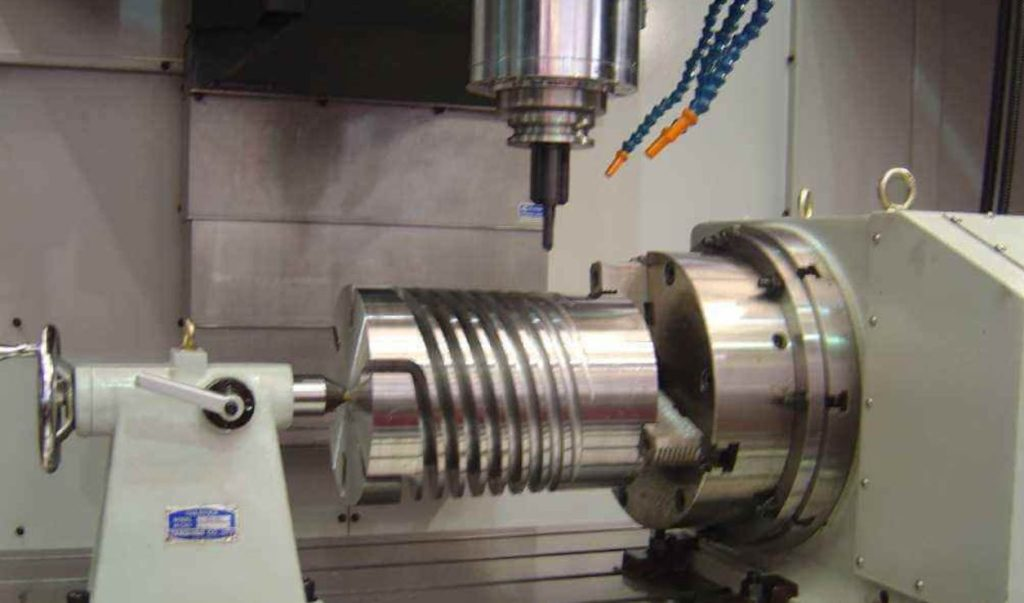

Once the programming is complete, the workpiece is secured on the 4-axis CNC machine. The machine then follows the programmed instructions and moves the cutting tool along the X, Y, and Z axes while simultaneously rotating the workpiece on the rotational axis. The cutting tool removes material from the workpiece, creating the desired shape and geometry.

During the machining process, coolant is often used to cool the cutting tool and flush away the chips. This helps to prolong the life of the tool and maintain the quality of the cut. The machining process is closely monitored by the operator or an automated inspection system to ensure that the part is being machined to the correct specifications.

Once the machining is complete, the finished part is inspected for quality and accuracy. Any deviations from the specifications are corrected by adjusting the machining parameters or performing additional machining operations.

What are the Types of 4-Axis CNC Machines?

There are several types of 4-axis CNC machines available, each with its own unique features and capabilities. The most common types of 4-axis CNC machines include:

Vertical Machining Centers (VMCs): These machines are designed for milling and drilling operations and are commonly used in the aerospace, automotive, and medical industries. VMCs typically have a vertical spindle and a table that can move in the X, Y, and Z axes. The rotational axis is usually provided by a rotary table or an indexing head.

Horizontal Machining Centers (HMCs): These machines are similar to VMCs but have a horizontal spindle. HMCs are often used for large and heavy workpieces and are commonly found in the automotive and aerospace industries.

Turning Centers: These machines are designed for turning operations and are commonly used in the manufacturing of cylindrical parts. Turning centers typically have a spindle that rotates the workpiece and a tool turret that holds the cutting tools. The rotational axis is provided by a live tooling system or a C-axis on the spindle.

Swiss-Type Lathes: These machines are designed for small and precise parts and are commonly used in the watchmaking, medical, and electronics industries. Swiss-type lathes have a unique design that allows for high-precision machining of small parts with complex geometries.

Applications of 4-Axis CNC Machines

4-axis CNC machines are used in a wide range of applications across various industries. Some of the common applications of 4-axis CNC machines include:

Aerospace Industry: The aerospace industry requires high-precision parts with complex geometries. 4-axis CNC machines are used to manufacture parts such as turbine blades, engine components, and structural parts. The ability to machine complex shapes and angles is essential for ensuring the safety and performance of aircraft.

Automotive Industry: The automotive industry also requires high-precision parts with complex geometries. 4-axis CNC machines are used to manufacture engine blocks, transmission parts, and other critical components. The ability to machine parts with tight tolerances and complex shapes is essential for improving the performance and fuel efficiency of vehicles.

Medical Industry: The medical industry requires precision parts for implants, surgical instruments, and other medical devices. 4-axis CNC machines are used to manufacture parts with complex geometries and tight tolerances, ensuring the safety and effectiveness of medical devices.

Electronics Industry: The electronics industry requires small and precise parts for smartphones, computers, and other electronic devices. 4-axis CNC machines are used to manufacture parts such as connectors, housings, and heat sinks. The ability to machine small parts with complex geometries is essential for meeting the demands of the electronics industry.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.