Advanced Printing Techniques for Cigarette Box Designs

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

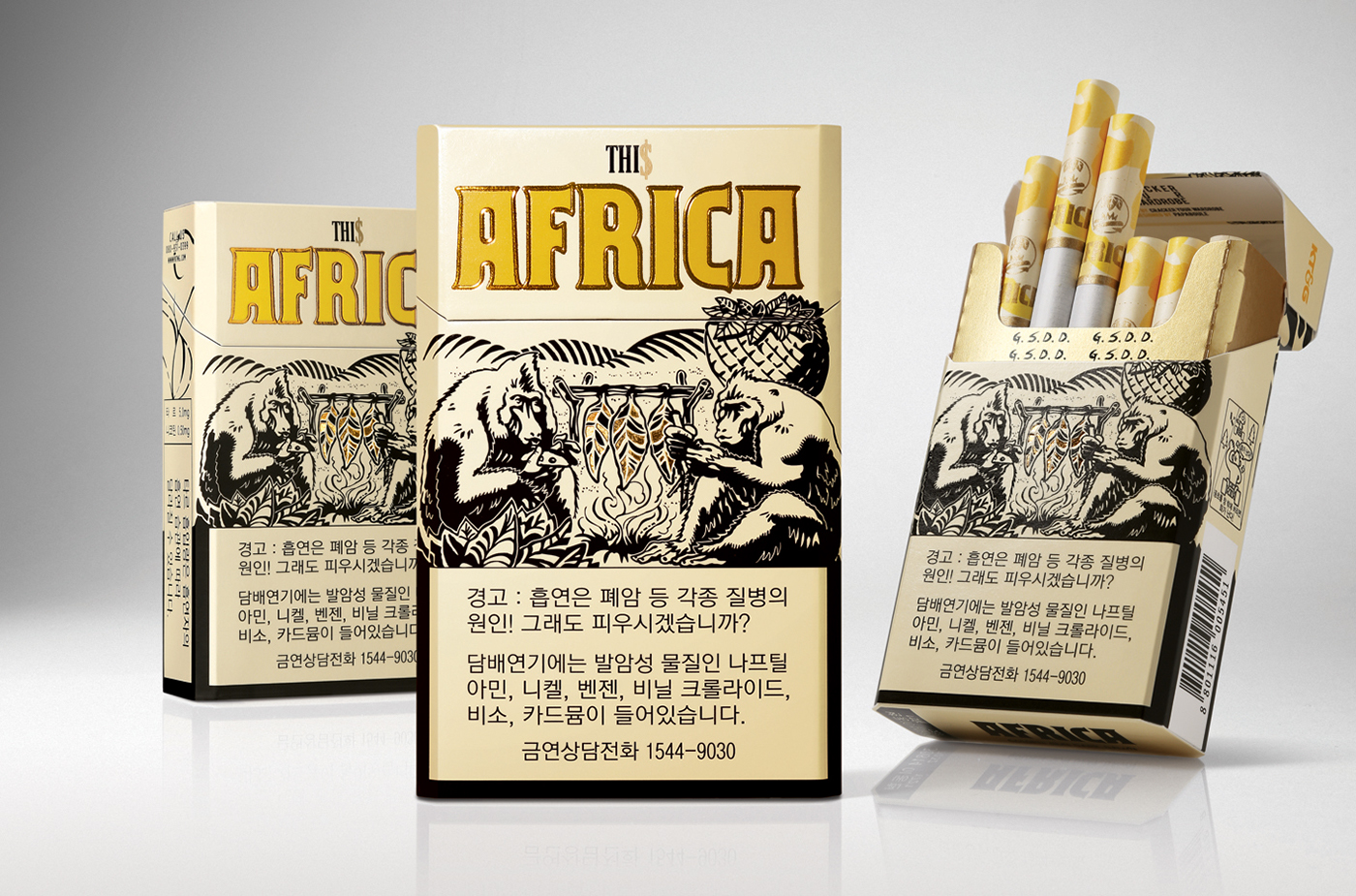

Cigarette packaging is no longer just a container; it is a crucial marketing tool that catches consumers’ attention. Today, advanced printing techniques make cigarette boxes stand out by combining creativity and technology. These innovations help brands to express their identity clearly while also complying with regulations. The art of printing on cigarette boxes has evolved significantly, and understanding these techniques is essential for manufacturers and designers.

3D Embossing and Debossing

Embossing and debossing are tactile printing techniques that add depth and texture to cigarette boxes. Embossing raises a design above the surface, while debossing pushes it into the material. This technique provides a luxurious feel and a unique look. The raised or sunken patterns catch light differently, creating visual interest.

Using 3D embossing allows designers to highlight logos or important brand elements. It adds sophistication and helps the package stand out on the shelf. The process requires precise machinery and special dies that shape the box’s surface during production. One advantage is that embossing doesn’t rely on color, so it works well even on simple or minimalistic designs.

Debossing offers a more subtle but elegant effect. It is often combined with other printing techniques like foil stamping to enhance the design further. The technique increases the sensory experience for consumers, making the box more memorable. It also reinforces brand identity by giving a tactile confirmation of quality.

Foil Stamping for a Metallic Shine

Foil stamping involves applying a thin layer of metallic foil to the custom cigarette box. This method produces shiny, reflective elements that catch the eye quickly. Gold and silver are popular foil colors, but other shades like blue, red, or green are also available. This versatility allows brands to customize their packaging uniquely.

The foil is pressed onto the box with heat and pressure, bonding it permanently to the surface. It can be used to emphasize logos, borders, or decorative patterns. Combining foil stamping with embossing creates an even more striking effect, giving a three-dimensional metallic look.

Apart from enhancing aesthetics, foil stamping increases the perceived value of the product. Consumers often associate metallic finishes with premium quality. Moreover, this technique offers durability because the foil is resistant to fading or scratching during handling and transport.

UV Coating for Vibrant and Durable Prints

UV coating is a finishing process that applies a glossy or matte protective layer on cigarette boxes. This coating cures quickly under ultraviolet light, which hardens the surface instantly. The result is a vibrant and durable finish that enhances colors and protects the design from damage.

UV coating makes cigarette boxes water-resistant and less prone to scratches or fingerprints. It is ideal for brands looking for a clean, polished appearance that lasts longer on shelves. This technique also offers flexibility, allowing selective coating on specific parts of the box. This is called spot UV coating.

Spot UV is used to highlight logos, text, or images, making them pop against the rest of the surface. This creates a contrast between shiny and matte areas, adding depth and style. The technology behind UV coating is also environmentally friendly since it produces fewer volatile organic compounds compared to traditional varnishes.

Digital Printing for Quick and Customizable Designs

Digital printing has revolutionized cigarette box production by allowing fast turnaround and customization. Unlike traditional printing methods that require plates and setup, digital printing uses a direct-to-surface process. This means designs can be easily modified or personalized without delays.

For limited editions or seasonal packaging, digital printing is a perfect choice. It offers sharp images, rich colors, and the ability to print complex patterns. Brands can test different designs without large investments, helping them respond quickly to market trends.

Though digital printing may not match the texture effects of embossing or foil stamping, it excels in delivering vibrant visuals. It also reduces waste because only the needed quantity is printed. This efficiency benefits both the environment and the budget.

Soft-Touch Lamination for a Premium Feel

Soft-touch lamination adds a velvety texture to cigarette boxes. It gives the packaging a smooth, pleasant surface that feels comfortable to hold. This effect appeals to consumers’ senses, creating a tactile connection with the product.

This lamination protects the box from dirt, moisture, and minor scratches. It also reduces glare, making the colors appear richer without a shiny finish. Soft-touch lamination is popular for luxury cigarette brands aiming to convey exclusivity.

Applying this lamination requires advanced machinery but results in a noticeable upgrade to the packaging quality. It can be combined with other printing effects like embossing or spot UV to create a layered sensory experience.

Lenticular Printing for Animated Visual Effects

Lenticular printing creates images that change or move when viewed from different angles. This is achieved by layering lenses over the printed surface. When a person tilts the cigarette box, they see different images or a sense of motion.

This technique grabs consumer attention because of its interactive and dynamic appeal. It allows brands to tell a visual story or show different product features in a single design. Lenticular printing requires precise alignment and specialized materials, but the impact on shelf presence is strong.

Besides eye-catching effects, lenticular printing enhances brand innovation perception. It is ideal for brands wanting to highlight technology or creativity in their marketing.

Holographic Effects for Futuristic Packaging

Holographic printing uses special films to produce rainbow-like, shimmering visuals. These holograms shift colors based on the light and viewing angle. This gives cigarette boxes a futuristic and high-tech look.

Holographic effects can cover the entire box or be used as accents on logos or patterns. The technique adds a sense of mystery and sophistication. It also serves as a security feature because holograms are difficult to counterfeit.

Brands using holographic printing attract consumers who seek modern and trendy designs. The technique requires precise lamination processes and often pairs well with matte or soft-touch finishes.

Sustainable Printing for Eco-Friendly Packaging

Sustainability is becoming a key concern in packaging. Advanced printing techniques now focus on reducing environmental impact while maintaining quality. Eco-friendly inks, recycled papers, and water-based coatings are common choices.

Many brands use soy-based or vegetable-based inks that are biodegradable and less toxic. This reduces pollution and improves worker safety. Sustainable packaging also involves minimizing waste during the printing process through digital printing and optimized layouts.

Consumers increasingly appreciate brands that care about the planet. Using sustainable printing methods aligns with these values, enhancing brand reputation and trust.

Security Printing for Anti-Counterfeiting

Cigarette brands face the challenge of counterfeit products, which damage brand image and revenue. Security printing techniques help protect packaging from fraud. These include microtext, UV-visible inks, and invisible patterns only seen under certain light.

Integrating security features with decorative printing creates packaging that is both attractive and safe. Brands can verify authenticity easily while maintaining aesthetic appeal. Some security elements can be combined with embossing or holographic effects for layered protection.

Security printing requires specialized technology and careful design. However, it is essential for maintaining brand integrity and consumer confidence.

Conclusion

Through innovation and skill, cigarette box design continues to evolve, delivering packaging that is beautiful, durable, and meaningful. These printing techniques play a vital role in shaping how brands communicate and connect with their customers. Whether it is the tactile sensation of embossing or the shimmering allure of holograms, each method adds a new dimension to the art of cigarette packaging. When combined thoughtfully, they create packaging that is both practical and exceptional. Custom cigarette box printing stands as a testament to this blend of creativity and technology in the tobacco industry today.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.