Applications of 310H Stainless Steel Seamless Pipe in the Power and Chemical Industries

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

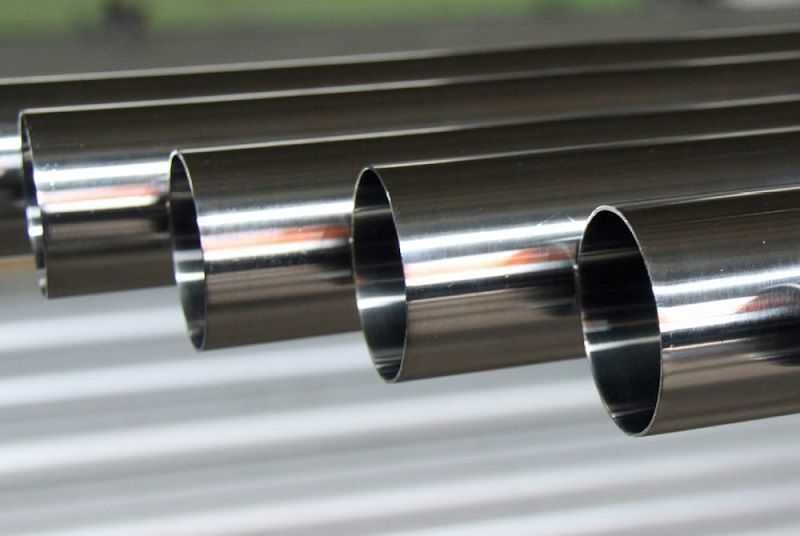

The 310H stainless steel seamless pipe is a versatile and durable material that plays a crucial role in industries that deal with high temperatures and harsh environments, particularly in the power and chemical sectors. Known for its exceptional resistance to oxidation and corrosion, this pipe is a popular choice for applications where heat, pressure, and corrosion resistance are essential. Its ability to maintain strength and reliability even in extreme conditions makes it a preferred material for various industrial applications.

Importance of 310H Stainless Steel Seamless Pipe

The 310H stainless steel seamless pipe is designed with high chromium and nickel content, which gives it outstanding resistance to oxidation at elevated temperatures. Unlike welded pipes, seamless pipes are formed without any joints, providing greater strength and pressure tolerance. This makes them ideal for critical applications in industries like power generation and chemical processing, where system integrity is essential.

Applications in the Power Industry

In the power industry, 310H stainless steel seamless pipe is widely used in high-temperature systems, especially in power plants, boilers, and heat exchangers. These systems operate under extreme conditions where pipes are exposed to high pressures and temperatures. The corrosion resistance and high strength of 310H stainless steel ensure that it can withstand these conditions and provide long-lasting service.

Boilers and Heat Exchangers: The pipes are commonly used in the construction of boilers and heat exchangers, where they are exposed to high pressures and temperatures. The material’s ability to resist corrosion in these environments ensures reliable performance.

Superheaters and Reheaters: In power plants, 310H stainless steel seamless pipes are used in superheaters and reheaters, which are critical components that maintain the desired temperature and pressure in steam systems.

Piping in Critical Systems: Due to its strength and resistance to thermal fatigue, 310H stainless steel seamless pipe is used in piping systems that carry high-temperature steam or gases, such as those found in nuclear power plants or fossil fuel power generation.

Applications in the Chemical Industry

The chemical industry deals with aggressive and corrosive substances, which makes the choice of piping material crucial. The 310H stainless steel seamless pipe is highly valued in this industry for its ability to withstand corrosion from chemicals and maintain its integrity in high-temperature environments.

Chemical Reactors and Furnaces: The high heat resistance and corrosion resistance make 310H stainless steel ideal for use in chemical reactors and furnaces, where pipes are exposed to corrosive chemicals and extreme temperatures.

Pipelines for Corrosive Materials: The chemical industry often requires pipes to transport corrosive liquids and gases. The ASTM B805 Inconel 725 Fasteners can be used alongside 310H pipes to secure the system, providing added protection against corrosion and ensuring the long-term durability of the system.

Exhaust Systems: The chemical industry also uses 310H stainless steel pipes in exhaust systems where high temperatures and corrosive gases are present. The material’s resistance to oxidation ensures that the pipes maintain their structural integrity over time.

Benefits of Using 310H Stainless Steel in Power and Chemical Industries

Heat Resistance: The pipes can withstand temperatures up to 1150°C in intermittent service, which is essential in high-temperature systems like boilers and reactors.

Corrosion Resistance: The high chromium and nickel content makes these pipes highly resistant to oxidation and corrosion, which is vital in environments exposed to chemicals, high pressures, and extreme temperatures.

Durability: The pipes offer excellent durability and long service life, even in harsh and demanding environments. This reduces the frequency of maintenance and replacement, ensuring the smooth operation of critical systems.

Strength: The strength of 310H stainless steel seamless pipes ensures they can handle high-pressure applications, making them suitable for power plants, refineries, and chemical plants.

Conclusion

The 310H stainless steel seamless pipe is a reliable material used extensively in the power and chemical industries. Its excellent heat resistance, corrosion resistance, and strength make it ideal for applications in high-temperature systems, boilers, chemical reactors, and exhaust systems. Whether in power plants or chemical processing units, the use of 310H stainless steel ensures that piping systems operate efficiently and remain durable over time, helping industries maintain consistent performance and reduce maintenance costs.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.