Automotive Engine Connecting Rods Market Insights: Growth, Trends, and Key Players in 2022

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

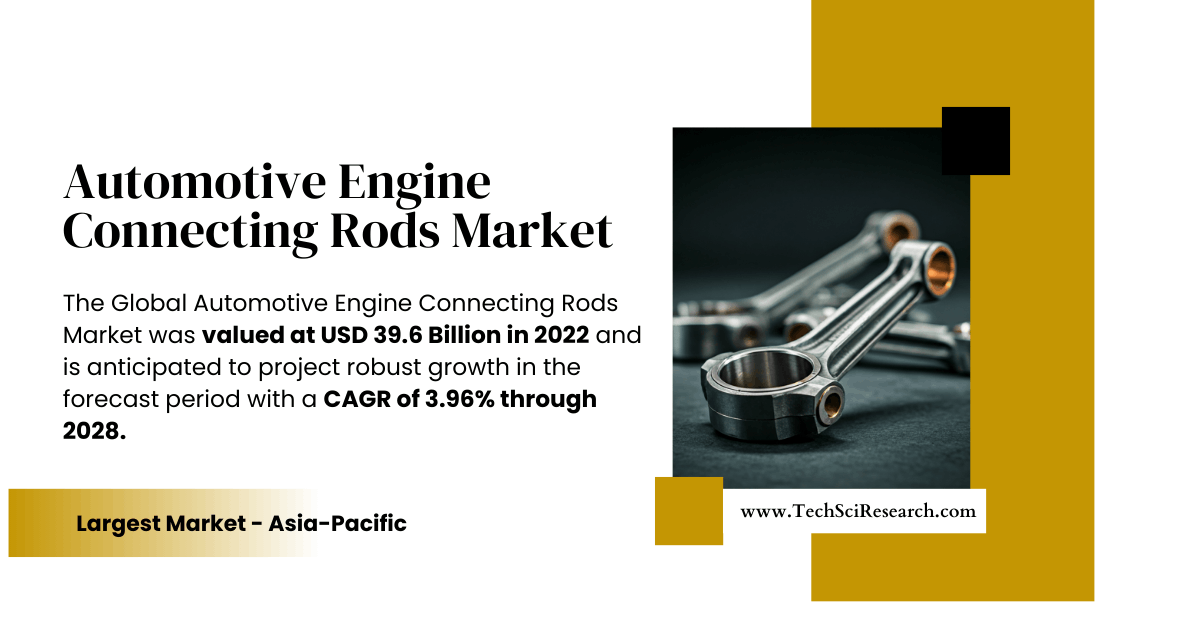

The Global Automotive Engine Connecting Rods Market has experienced significant growth, driven by the rising demand for automobiles worldwide. The market, valued at USD 39.6 billion in 2022, is projected to grow at a CAGR of 3.96% during the forecast period 2024-2028.

This report explores the dynamics, trends, challenges, and opportunities shaping the market.

Automotive Engine Connecting Rods Market Overview

Connecting rods serve a critical role in automotive engines, linking the piston to the crankshaft and facilitating power transmission. Continuous advancements in technology have led to the development of high-quality connecting rods that improve engine durability, strength, and performance.

Key Market Drivers

-

Growing Demand for Automobiles: The rise in vehicle ownership, particularly in emerging economies, is fueling demand for engine components.

-

Advancements in Material Science: The shift from traditional materials to high-strength alloys, aluminum, and titanium enhances performance and fuel efficiency.

-

Technological Innovations: Adoption of CNC machining, 3D printing, and Industry 4.0 technologies are optimizing production processes.

-

Regulatory Standards: Stringent emission norms are driving manufacturers to produce lightweight and efficient engine components.

Browse over market data Figures spread through 180 Pages and an in-depth TOC on the "Global Automotive Engine Connecting Rods Market” @ https://www.techsciresearch.com/report/automotive-engine-connecting-rods-market/20792.html

Automotive Engine Connecting Rods Market Segmentations

By Product Type

-

Steel Connecting Rods: Durable and widely used in commercial vehicles.

-

Aluminum Connecting Rods: Lightweight and preferred for high-performance and fuel-efficient vehicles.

-

Others (Composites & Titanium): Advanced materials offering superior strength and reduced weight.

By Vehicle Type

-

Passenger Vehicles: Largest market segment due to rising urbanization and disposable income.

-

Commercial Vehicles: Increasing demand from logistics and transportation industries.

-

Others (Specialty Vehicles): Includes high-performance and motorsport applications.

By Region

-

Asia-Pacific: Dominates the market with strong automotive manufacturing hubs in China, India, and Japan.

-

Europe: Home to premium and luxury car manufacturers, emphasizing innovation and sustainability.

-

North America: Strong presence of established brands focusing on performance and technological advancements.

-

Rest of the World: Emerging markets contributing to industry expansion.

Trends Shaping the Market

Lightweight Materials Adoption

Manufacturers are increasingly utilizing aluminum, titanium, and composite materials to enhance fuel efficiency and reduce emissions. These materials significantly lower the overall engine weight, improving vehicle performance.

Integration of Advanced Manufacturing Technologies

-

CNC Machining: Ensures precision in connecting rod production, reducing material wastage.

-

3D Printing: Enables complex designs and rapid prototyping, leading to improved performance characteristics.

-

Industry 4.0 and Smart Manufacturing: Enhances efficiency, reduces production costs, and improves product quality.

Sustainability and Environmental Responsibility

-

Recyclable Materials: Manufacturers are adopting eco-friendly materials to comply with sustainability goals.

-

Emission Reduction Efforts: Lightweight connecting rods contribute to fuel efficiency, aligning with global environmental regulations.

Customization and Performance Enhancement

-

Tailored Engine Components: Growing demand for customized connecting rods for sports cars and high-performance vehicles.

-

Enhanced Durability and Strength: New alloys and engineering techniques are extending the lifespan of engine components.

Emergence of Smart Connecting Rods

-

Embedded Sensors: Real-time monitoring of engine conditions such as stress, vibration, and temperature.

-

Predictive Maintenance: Smart technology enables proactive maintenance, improving engine reliability and efficiency.

Challenges Facing the Market

Raw Material Price Fluctuations

-

Unstable costs of metals like aluminum and steel impact production expenses and profitability.

Stringent Emission Regulations

-

Governments worldwide are imposing stricter norms on automotive emissions, requiring manufacturers to innovate continuously.

Competition and Cost Pressures

-

Intense competition among key players necessitates continuous innovation while maintaining cost efficiency.

Impact of Alternative Propulsion Technologies

-

The shift towards electric vehicles (EVs) poses a challenge, as EVs do not use traditional internal combustion engine components like connecting rods.

Opportunities in the Automotive Engine Connecting Rods Market

Growing Electric and Hybrid Vehicle Adoption

-

While EVs pose a challenge, hybrid vehicles still rely on internal combustion engines, presenting an opportunity for specialized connecting rods.

-

Research into lightweight and high-strength materials for hybrid engine applications is gaining traction.

Expansion into Emerging Markets

-

Rising vehicle demand in Latin America, Africa, and Southeast Asia offers new avenues for market growth.

-

Investments in local manufacturing facilities can help companies capture untapped potential in these regions.

Innovation and R&D Investments

-

Development of next-generation connecting rods that cater to alternative fuel and hybrid engines.

-

Research into nanomaterials and smart components for enhanced performance.

Competitive Landscape of Automotive Engine Connecting Rods Market

Leading companies in the Global Automotive Engine Connecting Rods Market include:

-

MAHLE GmbH – Pioneering in 3D-printed aluminum pistons and performance-enhancing components.

-

Thyssenkrupp AG – Specializing in precision-engineered automotive parts.

-

Cummins Inc. – Focused on high-performance engine components.

-

Arrow Precision Ltd. – Known for advanced connecting rod designs for motorsport and performance vehicles.

-

CP Carrillo – Expertise in performance-focused connecting rods for racing applications.

-

Albon Engineering and Manufacturing Plc – Leading supplier of forged and machined connecting rods.

Download Free Sample Report @ https://www.techsciresearch.com/sample-report.aspx?cid=20792

Customers can also request 10% free customization on this report.

Recent Developments

-

MAHLE’s 3D-Printed Aluminum Pistons: Successfully tested in Porsche 911 GT2 RS, increasing power output and efficiency.

-

Sustainable Manufacturing Initiatives: Companies are adopting greener practices in production to align with environmental regulations.

-

Technological Collaborations: Industry players are forming alliances to develop next-generation automotive components.

Future Outlook (2028)

The Global Automotive Engine Connecting Rods Market is expected to witness steady growth, driven by:

-

Advancements in Material Science: Continued innovations in lightweight, high-strength materials.

-

Increased Adoption of Smart Technologies: Enhanced monitoring and predictive maintenance capabilities.

-

Sustainability Initiatives: Eco-friendly materials and energy-efficient production methods.

-

Evolving Market Demands: Rising preference for performance-oriented and fuel-efficient vehicles.

Conclusion

The Global Automotive Engine Connecting Rods Market is undergoing a transformative shift, driven by technological advancements, material innovation, and the growing emphasis on sustainability.

While challenges such as emission regulations and the rise of electric vehicles pose hurdles, opportunities in hybrid vehicles, emerging markets, and smart technologies provide a promising outlook.

Market players must focus on innovation and strategic investments to stay competitive in this evolving landscape.

You may also read:

Automotive Hypervisor Market Analysis: Valued at USD 171 Million, Forecast to Grow at 5.92% CAGR

Ball Valves Market Report: USD {15.28 Billion} Valuation & Growth Forecast to {2028}

Saudi Arabia Vehicle Reparation Market Shows {CAGR} of 3.72%, Valued at USD 437 Million in 2022

E-Bikes Market: Overview of USD 32.84 Billion in [2022] & 7.94% CAGR by [2028]

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

![Airbags and Seatbelts Market Growth Forecast: USD 38.16 Billion [USD 38.16 Billion], Projected 7.10% CAGR to 2029](https://indibloghub.com/public/images/courses/67736d4bb9d96584_1735617867.png)