Autonomous Mobile Robots: Their Limits & Logistics Impact

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

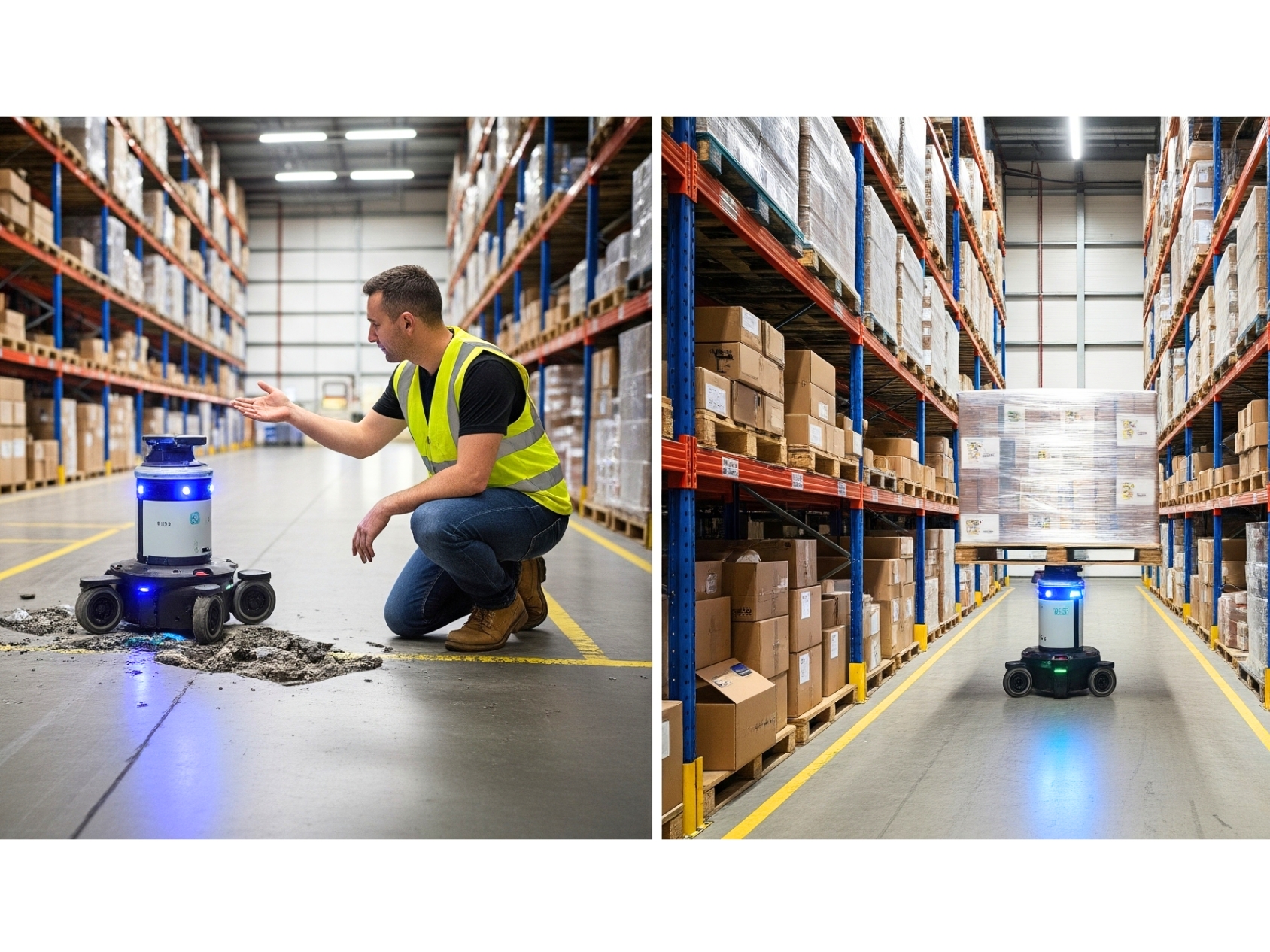

Autonomous Mobile Robots (AMRs) are becoming a common sight in warehouses and factories. These clever machines can pass around on their own, locating their manner and getting obligations finished without steady human assistance. They're pretty superb, however, similar to any new technology, they've their limits.

Limitations of AMRs

While it's stunning, AMRs are not first-rate. The following are a number of matters that they'll nonetheless find difficult:

- Dependency on Wi-Fi: In order to characteristic efficiently, many AMRs require a strong, reliable Wi-Fi connection. The robot can also become stressed or now not capable of functioning if the Wi-Fi signal is weak or drops. This means that groups must put money into the first-rate community infrastructure.

- Particular Environment Requirements: In preference, AMRs want even, easy surfaces. Their sensors can also turn out to be careworn with the aid of choppy flooring, ramps, moist or slippery places, or maybe extraordinarily dusty or dimly illuminated areas, making it difficult for them to navigate correctly.

- Initial Cost: While AMRs save cash over time, buying and tuning them can be luxurious up front. For smaller groups, this could be a giant impediment.

- Limited Heavy Lifting: Although effective AMRs are able to move big items, their lifting capacity is limited. Conventional forklifts or human operators may additionally be required for extremely heavy or strangely fashioned devices.

- Less Flexible Than Humans (Sometimes): Humans can react to surprising situations and alternate their responsibilities on the fly. An AMR, regardless of superior programming, may forestall and wait if it encounters an unexpected obstacle, requiring human intervention. They're remarkable for repetitive tasks, but less so for notably varied or unpredictable jobs.

- Interoperability Issues: If you buy AMRs from specific businesses, their software program structures won't communicate with each other without problems. This can make it hard to manipulate a blended fleet of robots.

- Mapping and Setup: While AMRs can build their own maps, the preliminary setup and mapping of a facility can nevertheless be a time-eating method. If the layout adjustments are often made, older or much less superior AMRs would possibly struggle to conform quickly.

- Sensor Limitations: AMRs use sensors like LiDAR and cameras to "see" their surroundings. These sensors can on occasion be tormented by bright light, dust, reflections, or even precise styles on the ground, main to false alarms or missed limitations.

- Not Always Smart Enough: While they can keep away from boundaries, an AMR may prevent in place of neatly navigate around a blockage that a human would effortlessly push aside or discover a specific course for. Sometimes, waiting for a human to clear the way is greater efficient than the robot looking to determine it out on its own.

The Helping Hands: AMRs in Logistics and Production

Despite their obstacles, AMRs are significantly contributing to the efficiency and smoothness of production and logistics.

One of their essential responsibilities is transferring goods around. AMRs can bring completed goods to storage, deliver uncooked substances to manufacturing areas, and circulate goods throughout a warehouse. They lessen the need for human exertion in those frequently monotonous and sometimes risky jobs through running constantly, around the clock.

- Order Picking and Fulfillment: AMRs can assist with order selection in extensive warehouses. They have the ability to supply product cabinets to human employees (items-to-character) or choose particular gadgets on their own. This significantly accelerates the order fulfillment process, resulting in quicker patron transport.

- Inventory Management: AMRs can help in monitoring stock tiers in real time by retaining a record of what they circulate. This results in improved typical control over the contents of the warehouse and fewer errors in inventory counts.

- Enhancing Safety: AMRs decrease the possibility of human employee accidents with the aid of taking over responsibilities like transferring massive items or operating in risky situations. They can also save you from clashes with human beings and other items due to their clever sensors.

- Increasing Speed and Efficiency: AMRs do not require breaks and perform continuously. This makes it possible for techniques to run continuously, which improves throughput, hastens production, and makes the delivery chain greater responsive.

- Freeing Up Human Workers: When robots deal with the repetitive and physically annoying duties, human employees can focus on greater complicated, hassle-fixing, or innovative work that truly calls for their specific talents.

- Adapting to Changes: Unlike older Automated Guided Vehicles (AGVs) that observe fixed paths, AMRs can regulate their routes in real-time in the event that they encounter limitations or if the warehouse format changes. This makes them an entire lot more bendy in dynamic environments.

- Integration with Other Systems: AMRs may be associated with extraordinarily clever structures in a factory or warehouse, like warehouse control structures (WMS). This permits an additional related and optimized operation.

In conclusion, self-sustaining cell robots are effective tools that might be reworking how items are moved and made. While they nonetheless have some hurdles to overcome, their benefits in terms of efficiency, protection, and productivity are clear. In spite of transforming global industries, we might believe that AMRs will become even more intelligent and capable as generations go by.

You most likely see improved productivity, greater cozy operations, and extra performance tactics as you reflect on how Autonomous Mobile Robots can revolutionize your industrial agency. These, in our opinion, are viable realities in preference to best beliefs. Please contact Dynamic Industrial for further information on how AMRs might also remodel your material management or to speak about your specific wishes. With reliable and effective AMR solutions, we're right here to help you with your course.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.