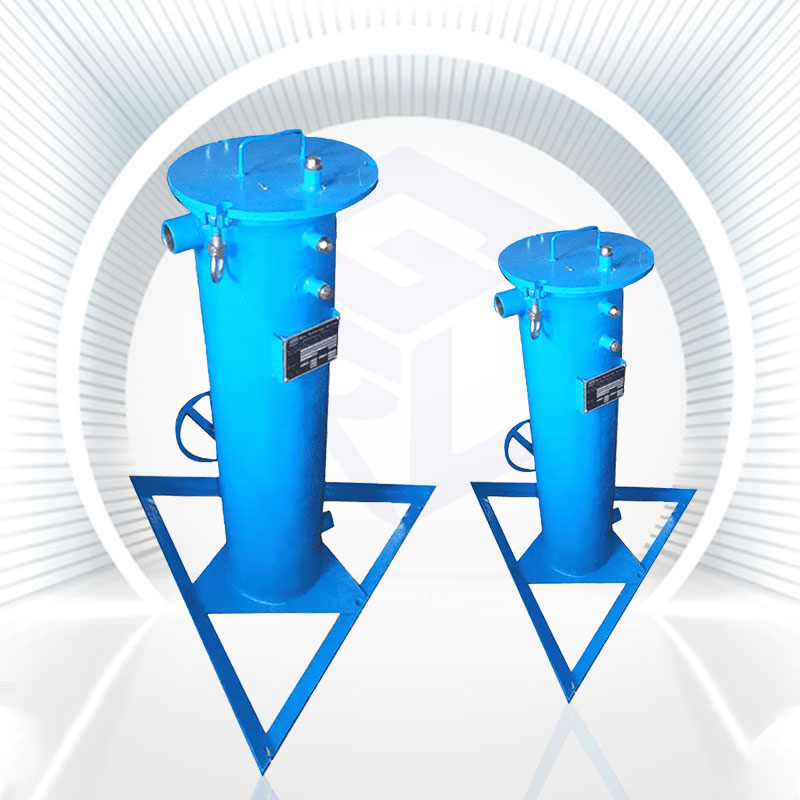

Bag Filter: Types & Choosing the Right Manufacturers

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

The process of filtration is very important for a precise production process, not just for the raw materials but also for the surrounding environment. Yes, you heard that right! Having a high-quality bag filter ensures that the dust or gas released during the production process does not cause any kind of suffocation to the workers or pollution in the air. The filters are used for different kinds of applications, like woodworking, the chemical industry, or food processing, where huge amount of dust or gas is released during the production process.

By using these bags, you are not just thinking about your staff but also protecting the environment. If you are considering buying a bag filter, it is important to first understand its types. Choosing the right filtration tool will help you enjoy the benefits of the bag filter.

Types of Bag Filters

These bags trap the solid particles from the gas, while the clean air can pass through the fabric. Here are the types of bag filters explained:

Air Jet Type Bag Filter:

It is the most common type of bag filter for those industries that release a lot of dust during their operations. The air jet removes the accumulated dust from the bag, ensuring that it provides efficient operations without the need for maintenance. It also reduces the frequency of maintenance of the filter bag. The air jet feature also reduces the need for manual intervention for maintenance. The versatility makes it suitable for various kinds of operations.

Plus Jet Type Bag Filter:

This bag filter uses compressed air to clean the bag surface. This cleaning action helps to remove the accumulation of dust particles, which is then securely collected in a hopper. This kind of bag filter is highly efficient in managing the high dust loads, making it apt for heavy-duty industries where huge pile of dust needs to be captured and removed. This bag filter is highly efficient, long-lasting, and durable.

Reverse Air Bag Filter:

It is a dust collector that uses the gentle flow of reverse airflow to clean the filter bags. It also removes the compressed dust without the need for compressed air, which makes it an efficient tool. It is a gentle process, which minimizes the load on the machine, enhancing it’s durability.

Tips to Select the Right Bag Filter

Understand the Requirement:

One of the major things to keep the mind while selecting the bag filter is to first understand the requirements of the industry. As the operator or your engineers need to understand which fabric easily catches the dust particles from the air or gas. Apart from that, it is also necessary to understand the size of the filter media. The process, condition, and environment should be considered before selecting the filter fabric along with the filter media design.

Operating Temperatures:

Selecting the right kind of fabric is essential for filtration, as gas is streamed at the inlet of the machine. The kind of dust collector inside the system, and when and how the dust will be cleaned from inside, be it pulse, jet, or the reverse air strategy. Some of these things should also be considered. Different kinds of bag filters react differently to different conditions and even temperature. Say, for example, if the temperature in the production area remains around 50°C, then the industrial-grade synthetic, natural fiber material can be selected.

On the other hand, if the operations are continuous with extreme fluctuations in temperature, then you should select high-quality PVC materials, nylon and cotton that can withstand the harsh environment.

Review the Material Properties:

Knowing the heat resistance properties of the material is essential. Different kinds of materials have different qualities and durability factors to withstand the heat. The heat resistance of cotton is 85°C, polyester can withstand 150°C, and PTFE can bear up to 260°C of heat. Apart from that, any specific kind of chemical, moisture, or gas is also a factor that should be considered into the type of material that is used.

Wrapping Up…

Selecting the right bag filters is as essential as it promotes sustainability. Apart from that, it also makes the environment safe for the workers. There are many bag filters to choose from, however, you need to select the one that suits the environment of your manufacturing area. It will give you more efficient results. If you are looking for a high-quality bag filter, then ‘GTS Filters and Systems’ is the one for you. They are properly formed to guarantee that there are no gaps in the overall system. The dirt particles and pollutants are precisely collected for interrupted smooth operations.

Frequently Asked Questions:

Question. What is a Bag Filter?

Answer :- It is a filter, as the name suggests, to capture the unwanted gas or pollutants that are released during the operations. It promotes sustainability and keeps the environment around the industry clean.

Question. What are the Limitations of the Bag Filter?

Answer :- This filtration machine uses dry compressed air, which adds to the energy cost. It requires a special type of fabric to filter the high tempature contaminants. Apart from that, the pulse jets cannot withstand the high moisture level, which will lead to deterioration in the quality of operation.

Question. How to Pick the Right Filter Bag?

Answer :- There are so many factors that should be considered while selecting a filter bag, like temperature, moisture, abrasion, and the type of dust particles. The industrial-grade synthetic is best for low average heat, but polyester works best in extreme heat.

Question. How Often Should the Filter Bag be Replaced?

Answer :- The life of the filter bag varies depending on it’s usage rate, moisture, chemical attack, and dust accumulation, among others.

Question. Are the Bag Filters Efficient?

Answer :- Yes, the bag filters especially from ‘GTS Filters and Systems’ are very reliable and efficient. They can control air pollution, protecting the equipment and the surrounding environment.

Question. Why Should You Invest in a Bag Filter?

Answer :- According to some of the government instructions, it is essential to follow the environmental regulations, ensuring that no harm is caused to the environment during the production process. The bag filter helps ensure that you are following a sustainable manufacturing process.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.