Bead Mill Machine: The Ultimate Solution for Fine Grinding and Dispersion

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In today's manufacturing world, creating high-quality, uniformity in particle size reduction, and efficient processes are critical in many industries including paints, inks, cosmetics, dental compounds, agrochemicals, pharmaceuticals, and in many other areas of manufacturing. Manufacturers depend on better quality equipment to get consistent results. Out of the many alternatives, Bead Mill Machine is the preferred option, preferred for ultra-fine grinding and excellent dispersion performance.

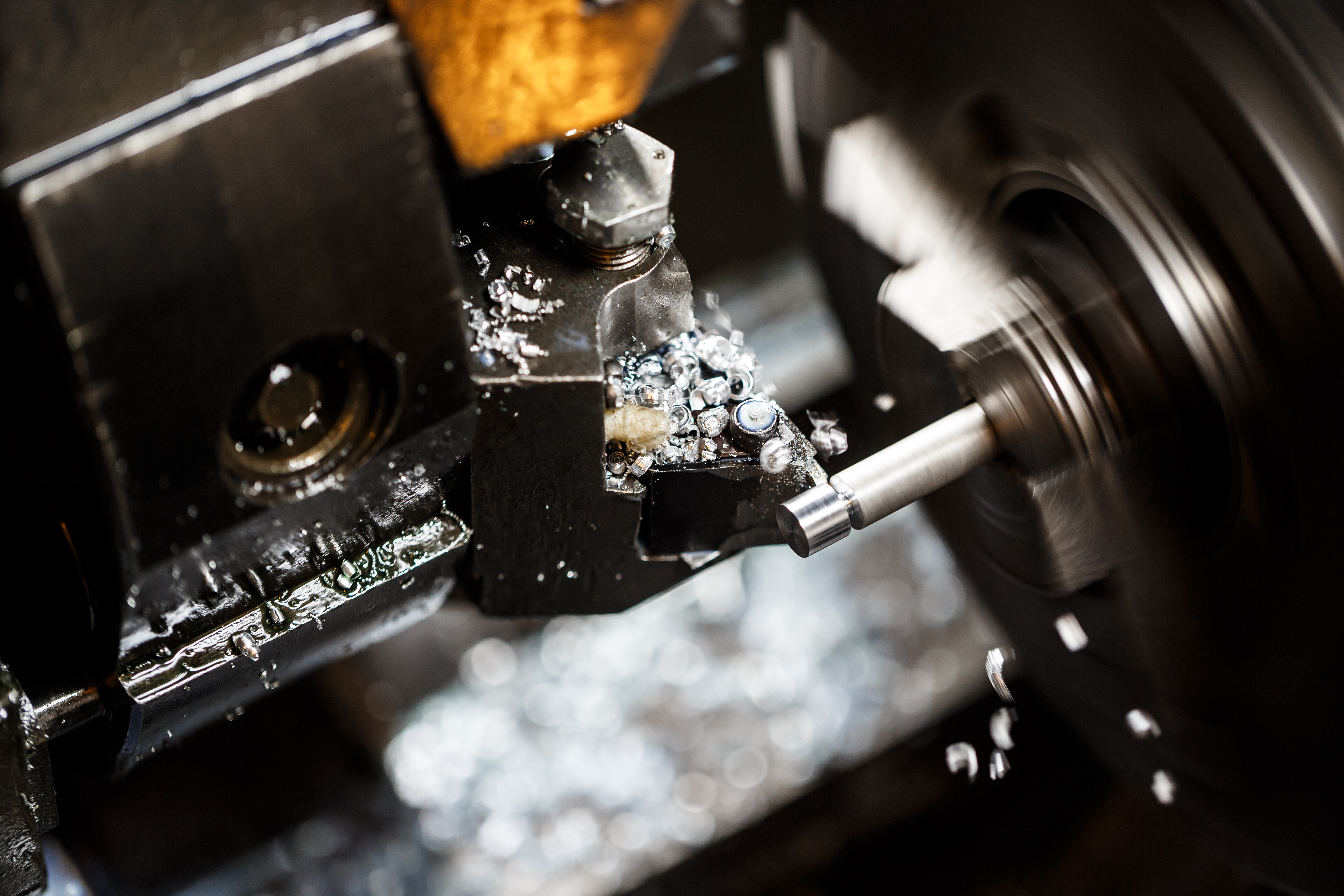

A Bead Mill Machine is a type of wet grinding mill that continues to grind and disperse materials in a liquid phase with grinding media, or beads. The end-product is a uniform mixture that is cool and consistent with reduced size and particles. This is ideal for applications that have specified standards and requirements that must be maintained.

How Does a Bead Mill Machine Work?

The Bead Mill Machine works by agitating small, grinding media (usually beads) within the chamber of the machine. Products are pumped into the chamber to be agitated so the grinding media can collide and interact with the particles in a high shear environment. The particles are therefore reduced to sub-micron and nano-sized material.

Particle size is dependent on the size of the grinding media and its rotational speed. The more fine the media, the smaller the particle size you are able to produce. This makes the Bead Mill Machines a great option for production work when maximizing surface area, stability, and uniformity are paramount.

Uses of Bead Mill Machine

The functionality of Bead Mill Machine is so diverse, you will never be without a use for it:

Paints and Coatings: To achieve perfect dispersion and smooth texture.

Pharmaceutical Products: For perfect distribution of the active ingredient.

Agrochemicals: Grinding down pesticides and fertilizers for top quality.

Cosmetic Products: For formulation consistency and better texture.

Inks and dyes: Vivid, stable and long-lasting colors.

In each of these industries, the Bead Mill Machine will facilitate your consistency, quality and efficiency.

The Significance of Grinding Media in Bead mills

The type of grinding media you choose will greatly affect the performance of any Bead Mill Machine. The three main types of grinding media used, include:

1- Stainless Steel Grinding Media

Stainless Steel Grinding Media is used in applications where durability, cost effectiveness, and low levels of contamination are desired. Stainless Steel media is corrosion resistant, heavy-duty, and well-suited for processing large batches or applications where metal contamination is not an issue. A stainless steel Bead Mill Machine is appropriate for coatings, inks, and industrial applications.

Although stainless steel is heavy, it can also wear on the inner chamber of the bead mill, and therefore should not be used if the bead mill does not utilize an inner lining. For this reason, stainless steel is generally preferred for coarse or medium grinding.

2. Zirconia Grinding Media

Zirconia Grinding Media is typically recognized as the best choice for high-energy milling and nano-scale grinding. Zirconia exhibits high density, toughness, and wear resistance that ensures these beads will work effectively while processing materials that are often very hard and abrasive materials. Similarly, Bead Mill Machines with zirconia beads can be effective for pharmaceutical, cosmetic, and high-purity product processing.

Zirconia also guarantees the lowest levels of contamination which is a critical requirement in any industry where stability and purity has to be maintained. Zirconia grinding media is more costly than stainless steel and can be poorly suited to some applications, but the long-life span, performance, and consistency of zirconia grinding media can lead to exceptional long-term value.

3. Ceramic Grinding Media

Ceramic Grinding Media allows "value" to be applied to the performance without overly considering the cost of manufacturing the beads. The beads are produced from a broad range of ceramic compounds such as alumina or silica, giving excellent mechanical strength and chemical resistance. The uses for bead mill machines with ceramic beads are mainly concerned with requiring medium grinding performance while maintaining reduced metal contaminations

Ceramic beads facilitate a reasonable balance between bead life, performance, and cost-effectiveness. Ceramic beads work well in industries where purity and consistency are critical, such as the production of inks, agrochemicals, and electronic materials.

Advantages of Implementing Bead Mill Machine

The recent development in Bead Mill Machines and customer availability is due to many unmatched benefits:

Improved grinding efficiency: Get to nano and sub-micron particle sizes quickly.

Minimum product loss: High throughput with low loss means lower raw material cost and minimum input.

Uniformity: Consistent particle size distribution.

Flexibility: Available in different capacities from lab-scale to full-scale industrial machines.

Versatile media options: Allows stainless steel grinding media, zirconia grinding media, and ceramic grinding media based on your process requirements.

Energy efficiency: Newer models are designed to save on energy when possible without losing production.

Selecting a Bead Mill Machine

When selecting a Bead Mill Machine to include in your production process, think about:

Material Compatibility: You will want to ensure that the grinding chamber and the grinding media you use are compatible with the material you are processing.

Desired Particle Size: You will want to make sure you pick the size and type of media that will yield the fineness needed for the grind.

Batch Size and Throughput: When choosing a mill, make sure the capacity is sufficient for your production needs. Capacity requirements are usually determined by a combination of batch size and production throughput.

Cleanliness of the Mill and Facility: This is particularly important for facilities that have many products.

Equipment Durability and Maintenance: Look for machines that have parts that are resistant to wear, or if they were to break down, are easy to replace.

The type of grinding media used in the Bead Mill Machine — whether it be Stainless Steel Grinding Media, zirconia grinding media, or ceramic grinding media will greatly affect each of the above points.

Conclusion

The Bead Mill Machine is a modern-day solution for obtaining highly precise grinding and dispersion for many industries. Its versatility, efficiency, and ability to work with a variety of grinding media make it a great option for manufacturers that want to elevate their product quality. Whether you chose Stainless Steel Grinding Media for durability, zirconia grinding media for applications with ultra-fine grinding, or ceramic grinding media for a good balanced performance option, the bead mill adapts for your production needs.

For companies looking to properly manage their production or simply meet the industry type standards that are demanding on how fine material must be processed, investing in a high quality Bead Mill Machine is indeed a worthwhile investment for not only the company but its future.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.