Best Industrial Shaft Alignment Services in Vadodara – Gujarat

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

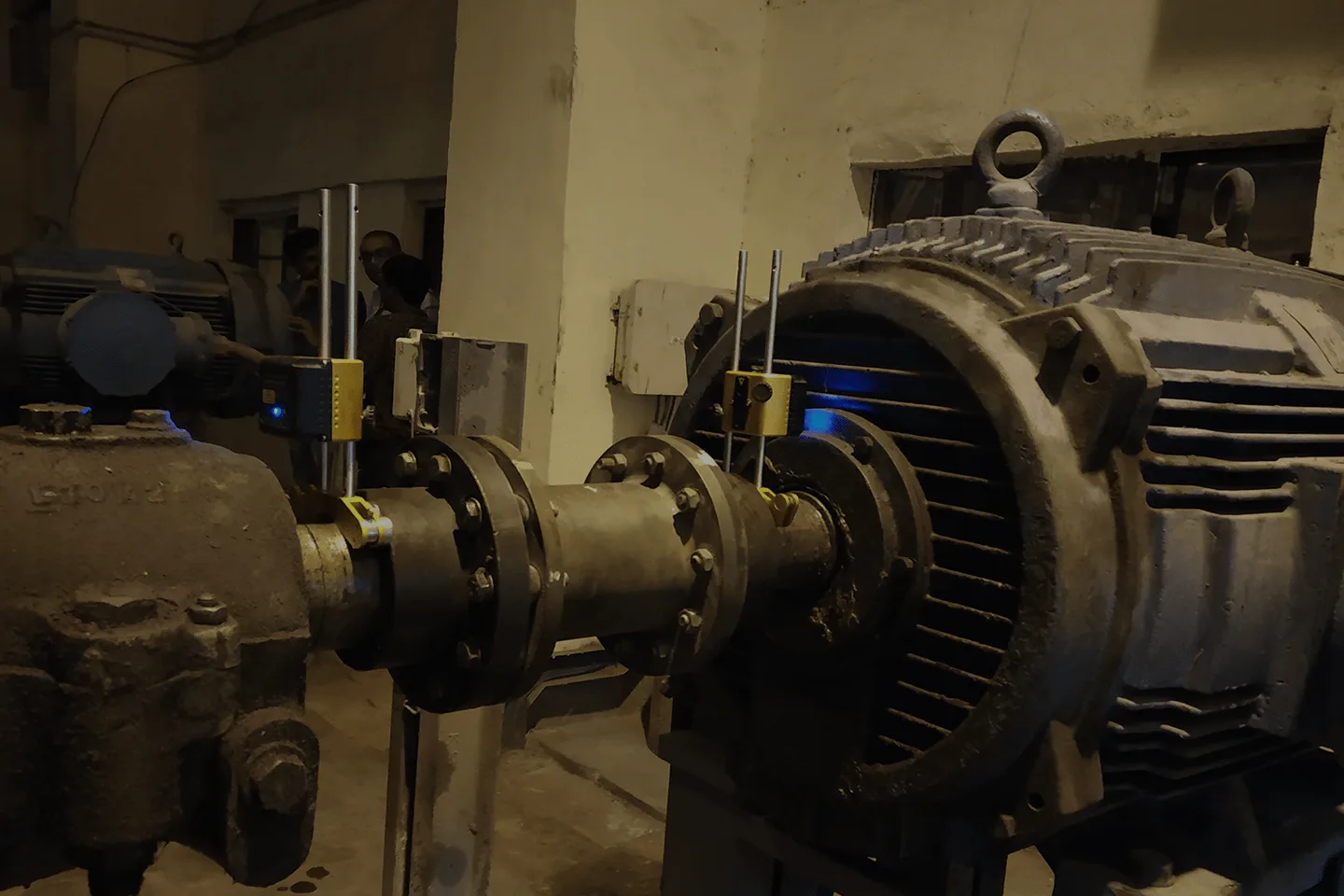

Shaft alignment is a vital component of machinery maintenance that has a direct impact on equipment longevity, performance, and operational efficiency. Proper alignment services help reduce wear and tear, minimize vibration, and prevent unexpected failures. Today, shaft alignment services in Vadodara are essential for ensuring smooth industrial operations and reducing costly downtime across manufacturing and processing units

Through this article, we will explore the full significance of shaft alignment, the various types of alignment services available in Vadodara—including laser shaft alignment, thermal growth compensation, and multi-coupling alignment—and explain why choosing professional alignment solutions is critical for long-term business success and plant reliability.

Why Shaft Alignment is Important in Vadodara Industries?

As you know, one of the most important industrial cities in Gujarat is Vadodara. It serves as a major hub for large-scale industries, including oil and gas, chemical, power generation, and textile sectors. These industries heavily rely on rotating machinery such as pumps, motors, compressors, turbines, and gearboxes to maintain continuous operations. However, if any of these components experience shaft misalignment, it can lead to serious consequences such as unplanned downtime, costly repairs, reduced equipment lifespan, energy inefficiency, and even safety hazards. This is why precise shaft alignment and regular maintenance are crucial for minimizing risk and ensuring reliability.

Types of Shaft Alignment Services in Vadodara

Laser Shaft Alignment

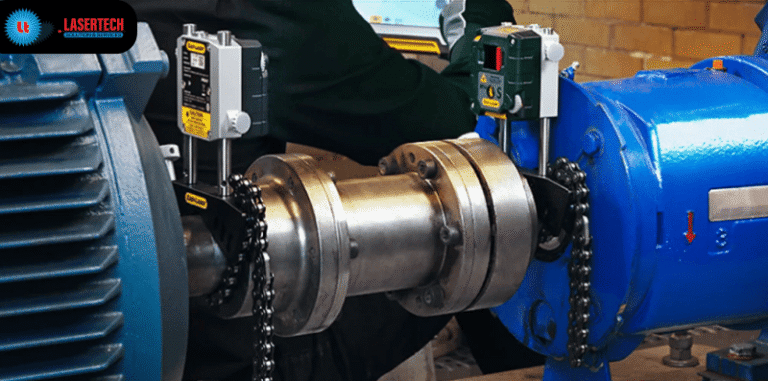

Now these days, laser shaft alignment services , including Shaft Alignment is most cutting-edge and extensively used technique in Vadodara's industries. It helps to measure and correct misalignment with extreme precision using advanced laser technology. Advantages consist of:

Fast and precise outcomes

Minimize human error

Comprehensive maintenance record reporting

Conventional Alignment Methods

Still, less frequently these days, traditional methods like calipers, dial indicators, and straightedges are also adopting in some applications. But, these techniques take longer and are less accurate as compared to laser alignment.

The Process of Shaft Alignment

There are many components are in including for shaft alignment service:

Initial Assessment: Technicians examine the equipment and measure misalignment by using the traditional instruments.

Data Analysis: To ascertain the degree and kind of misalignment (angular, parallel, or both) require analyzed of collected data.

Correction: Shims are added or removed for modifying the machine's position, and the alignment is examined again.

Final Verification: Before the machine is restarted, makes sure the set of measurements keep alignment satisfies industry standards.

Benefits of Professional Shaft Alignment Services

Take some point the following when choosing Right shaft alignment service in Vadodara Gujarat :

Select companies that employ technicians who have received training and certification.

More accuracy is provided by providers who use contemporary laser alignment equipment.

24/7 emergency shaft alignment ensures quick recovery and reduced downtime.

Fast response teams equipped with laser tools restore precision quickly.

These services are vital for industries like steel, chemical, and power.

Critical machinery—like pumps and motors—needs accurate alignment to perform efficiently.

Technicians work under pressure to minimize operational disruption.

Even complex multi-coupling systems can be aligned on-site.

Thermal growth and misalignment are diagnosed in real time.

Immediate correction prevents long-term mechanical damage.

A single misalignment can cause excessive wear and energy waste.

Hence, precision alignment protects both equipment and budgets.

For quality assurance, reports are a key component of the service.

Detailed before-and-after alignment readings show the impact clearly.

They verify the accuracy of the work done on-site.

Choosing the Right Shaft Alignment Service Provider

Proper alignment extends component life by lowering heat and friction.

Machines that are aligned efficiently need less energy to run.

By preventing alignment, fewer urgent repairs and part replacements are required.

Properly maintained Equipment gets less possibility of mishaps brought on by mechanical breakdown.

At The Final

Predictive maintenance services in Vadodara are playing a crucial role in supporting industries with advanced shaft alignment services. By utilizing cutting-edge laser alignment tools and skilled technicians, local businesses can significantly enhance equipment reliability and performance.

Accurate shaft alignment not only minimizes vibration and wear but also helps prevent unplanned downtime and costly repairs. When integrated into a broader predictive maintenance strategy, these services ensure machinery operates efficiently and safely.

Companies in Vadodara are increasingly investing in laser shaft alignment to boost productivity, prevent unplanned downtime, and extend machinery life through precise, proactive maintenance of critical rotating equipment.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.