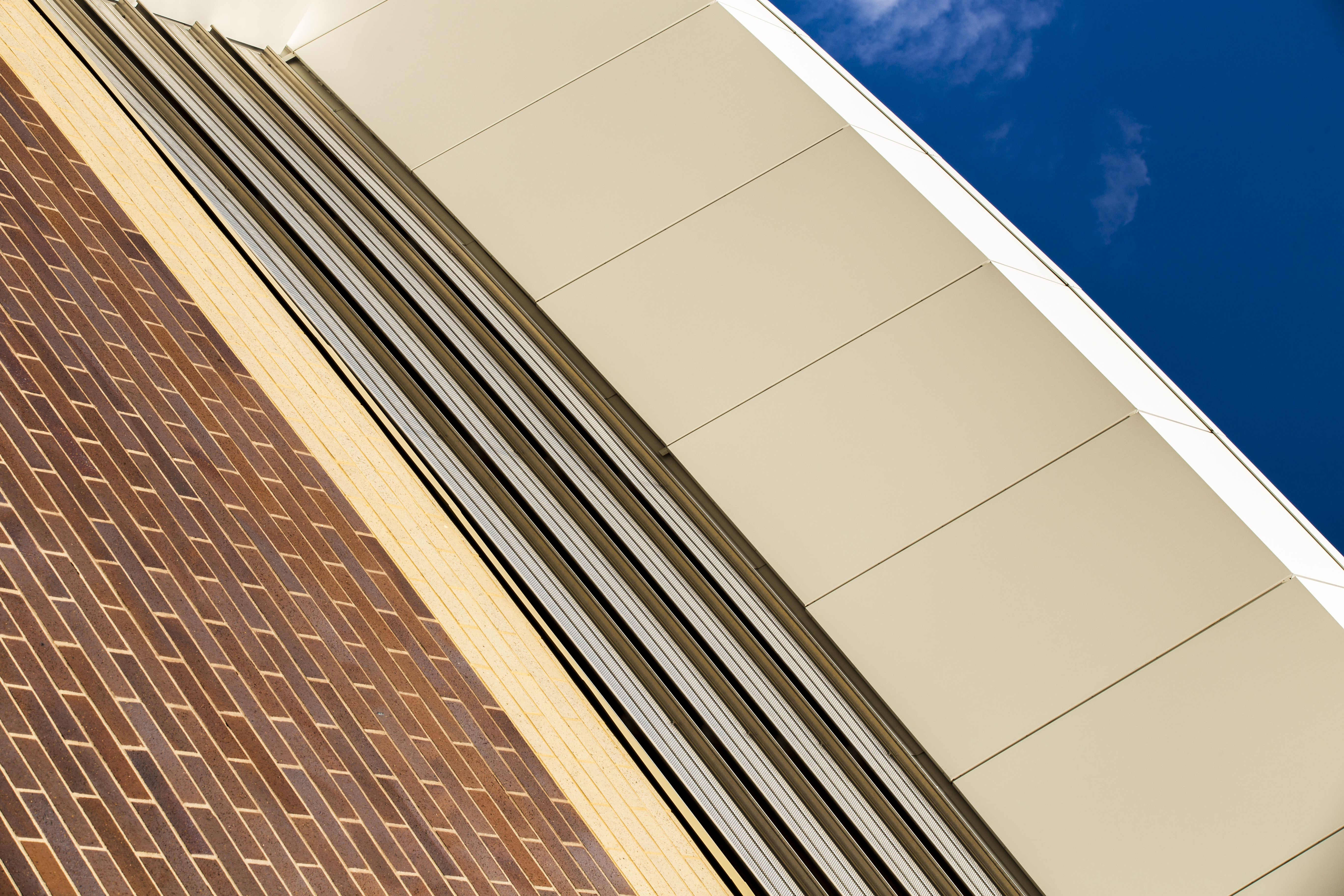

BIPV Cladding Advantages and Applications in Modern Architecture

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Building-integrated photovoltaics (BIPV) cladding combines solar energy technology directly into the exterior surfaces of buildings, allowing structures to generate electricity while serving as protective and aesthetic facades. BIPV cladding replaces traditional cladding materials with solar panels, offering a dual function that can reduce energy costs and carbon footprints.

This innovation integrates seamlessly with architectural designs, making it an attractive solution for sustainable construction without compromising style or function. It appeals to those focused on energy efficiency, sustainability, and modern building practices.

As the demand for renewable energy solutions grows, BIPV cladding provides a practical way to harness solar power without additional space. Understanding its benefits and applications helps clarify why it is gaining momentum in the construction industry.

Core Concepts of BIPV Cladding

BIPV cladding combines photovoltaic technology with building envelope elements, transforming exterior surfaces into power-generating units. It involves various system types and materials designed to balance energy production and architectural function, focusing on performance and integration.

Definition and Functionality

Building-Integrated Photovoltaic (BIPV) cladding replaces or covers standard exterior walls with solar panels that generate electricity. Unlike traditional solar panels added to rooftops, BIPV cladding is part of the building’s skin, serving both structural and energy functions.

The cladding systems capture sunlight and convert it into electrical energy through photovoltaic cells embedded in or attached to the building façade. It also provides weather protection, thermal insulation, and aesthetic value.

Types of Photovoltaic Cladding Systems

BIPV cladding types include rigid panels, thin-film laminates, and semi-transparent modules. Rigid panels use crystalline silicon cells, notable for efficiency and durability. Thin-film options use materials like CIGS or CdTe, offering flexibility and lighter weight but typically lower efficiency.

Semi-transparent modules can integrate with windows or glass façades, allowing light while generating power. The choice depends on desired transparency, weight restrictions, and architectural design requirements.

Integration with Building Materials

BIPV cladding requires careful integration with materials such as glass, metal, or composite panels. It replaces traditional façade materials, so it must meet standards for fire resistance, wind load, and thermal performance.

Installation can occur as prefabricated panels or in situ applications. Interfaces with existing building systems, like electrical wiring and weatherproofing layers, are critical for long-term reliability.

Key Benefits and Performance Metrics

BIPV cladding reduces building energy costs by producing onsite solar power. It supports sustainability goals by lowering carbon footprint and enabling net-zero energy buildings.

Performance is measured by efficiency (percentage of sunlight converted to electricity), durability (weather resistance and lifespan), and integration quality (impact on building insulation and structural integrity). Optimal designs maximize power output without compromising façade functions.

Applications and Design Considerations

BIPV cladding serves multiple roles, combining structural, aesthetic, and energy-producing functions. Designers must address integration challenges, energy goals, mechanical installation, and legal standards to ensure performance and compliance.

Architectural Integration and Aesthetics

BIPV cladding can replace conventional facade materials, offering a sleek, modern look with integrated solar cells. It supports diverse designs, including flat panels, curved surfaces, and custom shapes to match architectural intent.

Colors and finishes vary, with options ranging from transparent to opaque and tinted modules, enabling seamless blending with building exteriors. The choice often balances light transmission and solar efficiency.

Designers must consider module size, orientation, and shading factors to maintain visual coherence and ensure maximum sunlight exposure. The cladding often becomes a defining element of the building’s exterior, requiring coordination with architects and facade engineers.

Energy Efficiency and Sustainability

BIPV cladding generates electricity on-site, reducing reliance on external power sources. It converts building surfaces into productive energy assets without additional space use.

Energy output depends on factors like panel efficiency, facade orientation, and climate. South-facing vertical claddings typically produce less energy than inclined roof panels but remain valuable for partial energy needs.

The integration of BIPV supports green building certifications such as LEED and BREEAM by improving energy profiles and reducing carbon footprints. It also contributes to thermal insulation when combined with appropriate backing materials.

Installation Requirements

Installing BIPV cladding demands specialized mounting systems that accommodate electrical wiring and ensure structural stability. The support framework must align with standard cladding systems yet provide access for maintenance.

Electrical connections require weatherproofing and must comply with building codes. Coordination between structural engineers, electricians, and contractors is critical to avoid delays.

Weight considerations are essential; the cladding should not overload the supporting walls. Fire safety and impact resistance are also evaluated during the selection of materials and installation methods.

Regulatory Compliance and Certification

BIPV cladding must meet building codes related to structural integrity, fire resistance, and electrical safety. It often requires approval from local authorities before installation.

Certifications such as IEC 61215 (solar module performance) and UL 1703 (safety standards) validate product reliability. Compliance with energy codes like the International Energy Conservation Code (IECC) is mandatory in many jurisdictions.

Proper documentation and testing ensure the system qualifies for government incentives or rebates. Understanding regional regulations helps avoid legal issues and supports project financing.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.