Cellulose Acetate Powder Manufacturing Plant 2024: Detailed Project Report, Cost Analysis and Raw Materials Requirement

Cellulose acetate powder is a bio-based, biodegradable, and versatile material derived from natural cellulose, primarily obtained from wood pulp or cotton fibers. This fine powder is a modified cellulose form, created by acetylation, which replaces some of the hydroxyl groups in the cellulose molecule with acetyl groups. As a result, the powder exhibits improved properties such as enhanced durability, flexibility, and resistance to moisture and chemicals. It finds extensive applications in various industries, including textiles, plastics, films, coatings, and even pharmaceuticals. Its utility ranges from forming the base of bioplastics to acting as a crucial additive in the manufacturing of eco-friendly products.

The cellulose acetate powder market is primarily driven by the growing emphasis on sustainable materials as industries and consumers pivot towards environmentally responsible practices. The increasing use of cellulose acetate in bioplastics, which are vital for reducing plastic pollution, is a significant driver. Additionally, its application in textiles as a replacement for synthetic fibers and its role in creating biodegradable filters for cigarettes further boosts market growth. The rising demand for eco-friendly coatings and films in the packaging and construction sectors also supports the expansion of this market.

IMARC Group’s report titled “Cellulose Acetate Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” offers a comprehensive guide for setting up a cellulose acetate powder manufacturing plant.

The report includes the following information:

Market Analysis:

The material's properties, such as biodegradability and renewability, resonate with governmental regulations and corporate sustainability goals, further enhancing its adoption. The future of the cellulose acetate powder market is shaped by several emerging trends, most notably the development of advanced bioplastics and green technologies. Innovations in enhancing the material's performance for industrial uses, such as improved thermal stability and extended shelf-life for packaging applications, are expected to propel its demand. The growing consumer preference for eco-conscious products in cosmetics and personal care, where cellulose acetate is used as a binding agent, is another notable trend.

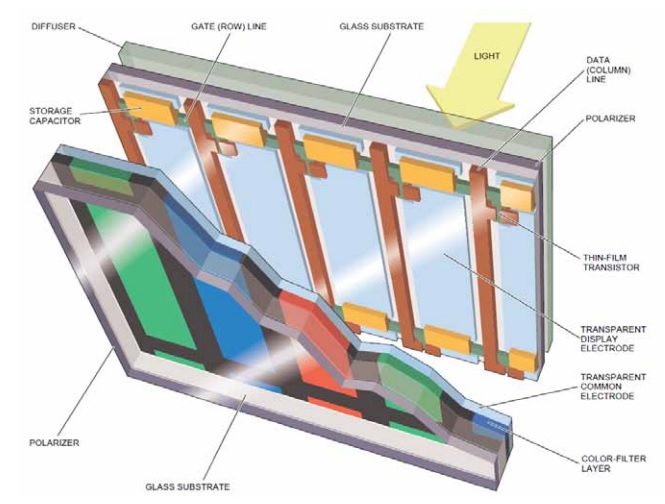

Furthermore, research and development focused on creating high-strength and multi-functional cellulose acetate blends are paving the way for its application in niche markets like electronics and advanced composites. As industries worldwide strive to meet stringent environmental regulations, the cellulose acetate powder market is poised for sustained growth, driving a transition toward a more sustainable future.

Market Trends

Market Breakup by Segment

Market Breakup by Region

Price Analysis

Impact of COVID-19

Market Forecast

Request for a Sample Report: https://www.imarcgroup.com/cellulose-acetate-powder-manufacturing-plant-project-report/requestsample

Project Overview

This section offers detailed information related to the process flow and several unit operations involved in a cellulose acetate powder manufacturing plant project. Moreover, information related to raw material requirements and mass balance has further been provided in the report with a list of necessary technical tests as well as quality assurance criteria.

Product Overview

Unit Operations Involved

Mass Balance and Raw Material Requirements

Quality Assurance Criteria

Technical Tests

Key Requirements and Costs

This section provides an analysis encompassing insights, including land location, selection criteria, location significance, environmental impact, and expenditure for cellulose acetate powder manufacturing plant setup. Besides this, the report further offers information related to plant layout and factors influencing the same. Additionally, other expenditures and requirements related to packaging, utilities, machinery, transportation, raw materials, and human resources have also been included in the report.

Land, Location, and Site Development

Plant Layout

Machinery Requirements and Costs

Raw Material Requirements and Costs

Packaging Requirements and Costs

Transportation Requirements and Costs

Utility Requirements and Costs

Human Resource Requirements and Costs

Project Economics:

This section covers a comprehensive analysis of the project economics for setting up a cellulose acetate powder manufacturing plant. This comprises the analysis and detailed understanding of capital expenditure (CapEx), operating expenditure (OpEx), taxation, depreciation, profitability analysis, payback period, NPV, income projections, liquidity analysis, uncertainty analysis, and sensitivity analysis.

Capital Investments

Operating Costs

Expenditure Projections

Revenue Projections

Taxation and Depreciation

Profit Projections

Financial Analysis

Browse the Full Report with the Table of Contents: https://www.imarcgroup.com/cellulose-acetate-powder-manufacturing-plant-project-report

Customization Available:

Production Capacity: Draft the machinery selection and plant layout to align with the expected scale of production, which can range from small-scale operations to large industrial setups.

Automation Levels: Modify the level of automation based on labor availability, budget constraints, and technical expertise from semi-automated processes to fully automated systems.

Location Adaptation: Customize the plant’s location to strategically align with local market demand, ensure efficient access to raw materials, utilize available labor resources, and adhere to regional regulatory requirements, thereby maximizing operational efficiency and cost-effectiveness.

Product Flexibility: Encompass processes and machinery that can handle numerous product variations. This, in turn, can enable the plant to cater to diverse market demands.

Sustainability Features: Incorporate various cellulose acetate powder options, including renewable energy integration, waste management systems, energy-efficient machinery, etc., to meet sustainability goals.

Raw Material Sourcing: Tailor the supply chain strategy to enable cost-effective and reliable access to raw materials specific to client requirements or the region.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company excel in understanding its client’s business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.