Google Ads Done Right – More Clicks, Less Waste!

Google Ads Done Right – More Clicks, Less Waste!

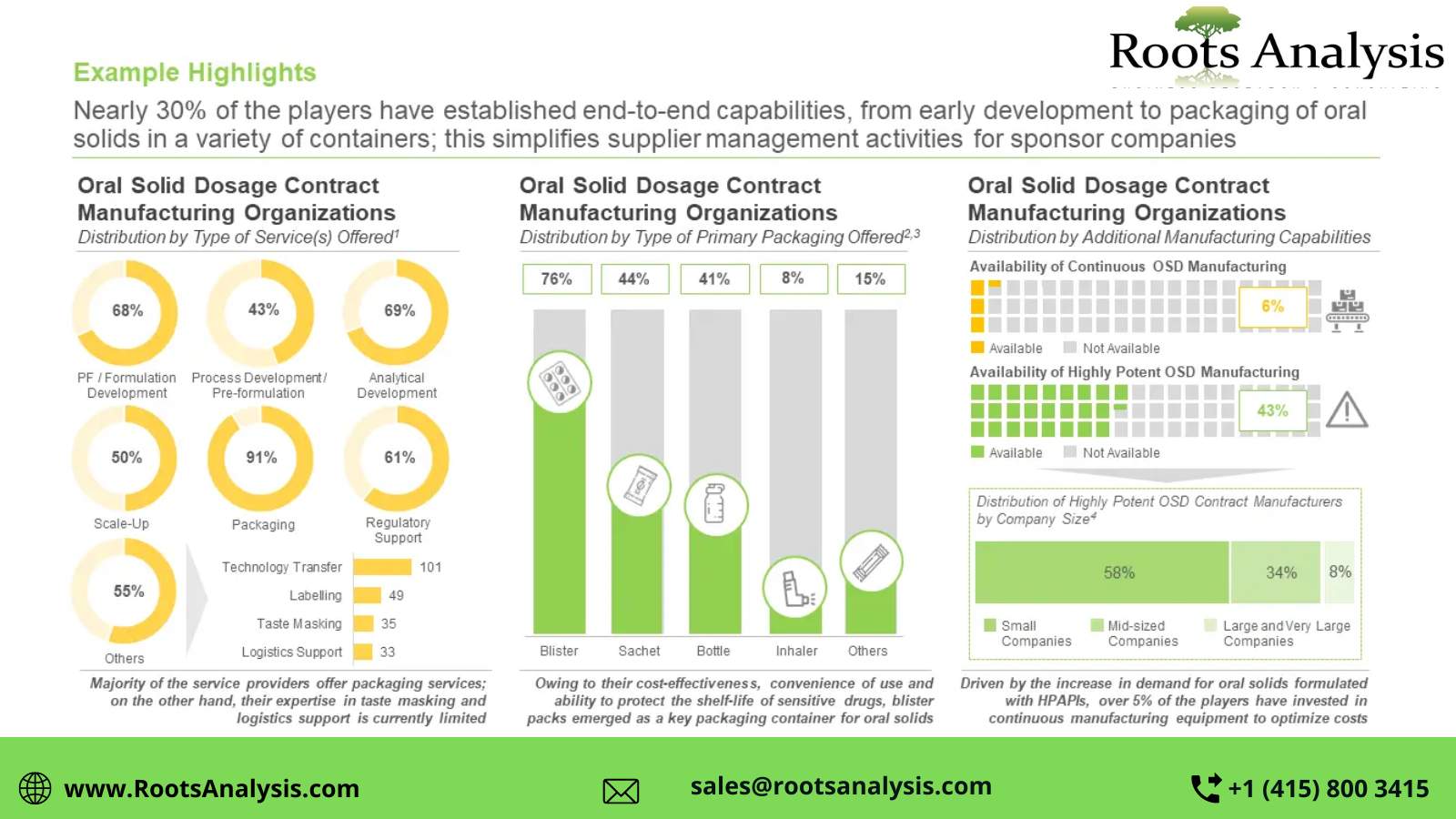

Ceramic Fiber Market Analysis, Dynamics, Forecast and Supply Demand 2031

Written by Shweta Dixit » Updated on: June 17th, 2025

The global ceramic fiber market is set to experience significant growth over the coming years. Projected to reach a market size of US$2.9 billion by 2030, up from US$1.6 billion in 2023, the market is expected to register a compound annual growth rate (CAGR) of 7.6% from 2023 to 2030.

For Full Industry Insights: https://www.fairfieldmarketresearch.com/report/ceramic-fiber-market

The ceramic fiber market is experiencing robust growth, driven by increasing demand across various industries. Key applications include aerospace, petrochemicals, and manufacturing, which are fostering market expansion. Continuous research and development (R&D) efforts have led to innovations in ceramic fiber materials, enhancing their thermal insulation and mechanical properties. These advancements contribute to the material's versatility and broad application spectrum.

Growing industrialisation in emerging economies amplifies the global demand for ceramic fiber, with Asia-Pacific emerging as a major market player due to its flourishing manufacturing sector. The ceramic fiber's role in promoting energy efficiency and reducing carbon footprints is a pivotal driver, aligning with global sustainability goals. Despite the market's positive trajectory, challenges such as volatile raw material prices and regulatory constraints pose potential obstacles to sustained growth. Intense competition prevails among key market players, prompting innovations and strategic collaborations to gain a competitive edge.

Key Growth Determinants

Growing Industrialisation and Infrastructure Development

The ceramic fiber market is propelled by the relentless pace of global industrialisation and infrastructure development. As emerging economies invest heavily in construction, manufacturing, and energy projects, the demand for high-performance materials like ceramic fibers has surged. These fibers find extensive use in insulation for high-temperature applications, lining for industrial furnaces, and other critical processes in sectors ranging from petrochemicals to power generation. The expansion of industries necessitates efficient and durable materials, positioning ceramic fibers as a key component in modern industrial applications.

Increasing Emphasis on Energy Efficiency

In a world increasingly focused on sustainability and energy conservation, ceramic fibers emerge as vital contributors to enhanced energy efficiency. With exceptional thermal insulation properties, these fibers play a pivotal role in reducing heat loss across various industrial processes. Governments, environmental agencies, and industries worldwide are actively promoting energy-efficient solutions. As a result, ceramic fibers are in high demand for applications where precise temperature management is essential. Their ability to minimise thermal conductivity and withstand high temperatures positions them as integral components in the pursuit of eco-friendly and energy-conserving industrial practices.

Aerospace and Automotive Innovation

The ceramic fiber market experiences a substantial boost from continuous innovation in the aerospace and automotive industries. As these sectors evolve, there is a growing demand for advanced materials that contribute to lightweight, improved performance, and enhanced durability. Ceramic fibers, characterised by their high strength-to-weight ratio, exceptional thermal resistance, and resistance to chemical corrosion, align perfectly with the stringent requirements of aerospace and automotive applications. The ongoing pursuit of innovation in these industries, driven by the need for fuel efficiency, reduced emissions, and enhanced functionality, ensures a sustained demand for ceramic fibers. These materials play a crucial role in the development of cutting-edge components for aircraft, automobiles, and other transportation systems.

Major Growth Barriers

High Cost of Production and Raw Materials

One significant restraint in the ceramic fiber market is the high cost associated with both the production process and the raw materials used. The manufacturing of ceramic fibers involves advanced technologies and energy-intensive processes, contributing to elevated production costs. Additionally, the raw materials required, such as alumina and silica, can be expensive. The overall cost structure poses challenges to market growth, especially in price-sensitive industries, limiting the widespread adoption of ceramic fibers.

Health and Safety Concerns

Certain types of ceramic fibers, particularly those containing refractory ceramic fibers (RCFs), raise health and safety concerns. Prolonged exposure to airborne respirable fibers during handling and installation can potentially lead to respiratory issues, including lung diseases. Occupational health and safety regulations in various regions impose strict guidelines on the handling, use, and disposal of these materials. Compliance with such regulations adds operational complexities and costs for industries utilising ceramic fibers, influencing decision-making and potentially hindering market expansion.

Key Trends and Opportunities

Increasing Demand in the Renewable Energy Sector

The ceramic fiber market is witnessing a trend of growing demand in the renewable energy sector, particularly in applications related to solar power and energy storage. Ceramic fibers are valued for their high-temperature resistance and thermal insulation properties, making them suitable for use in components like solar panels and energy storage systems. As the renewable energy industry continues to expand, the demand for ceramic fibers in these applications is expected to rise.

Advancements in Nanotechnology for Enhanced Properties

Ongoing research in nanotechnology is influencing the ceramic fiber market, with a focus on enhancing the properties of these fibers. Nanomaterials are being incorporated into ceramic fibers to improve strength, thermal conductivity, and other performance characteristics. This trend not only contributes to the development of more advanced ceramic fiber products but also opens up new possibilities for applications in cutting-edge technologies.

Sustainable and Eco-friendly Products

The trend toward sustainability and eco-friendly practices is impacting the ceramic fiber market. Manufacturers are increasingly focusing on developing sustainable alternatives, such as bio-based or recycled ceramic fibers. This shift is driven by both regulatory pressures and consumer preferences for environmentally friendly products. As sustainability becomes a key consideration across industries, the adoption of eco-friendly ceramic fibers is likely to gain momentum.

Regional Frontrunners

Asia Pacific Holds a Commanding Share

The Asia Pacific region continues to assert itself as the largest revenue-contributing region in the global ceramic fiber market. This dominance is driven by the region's robust industrial growth, particularly in sectors that heavily rely on ceramic fiber applications, such as manufacturing, construction, and petrochemicals. In countries like China and India, the expanding manufacturing and construction activities, coupled with a burgeoning petrochemical industry, have significantly increased the demand for ceramic fibers. The construction boom in the Asia Pacific region, driven by urbanisation and infrastructure development, has led to a substantial uptick in the use of ceramic fibers for applications like insulation in buildings and high-temperature materials in construction projects.

North America Likely to Witness Significant Growth

The forecast for the ceramic fiber market in North America indicates a significant growth trajectory, underlining the region's potential for increased sales in the coming periods. This growth is attributed to several factors that contribute to the heightened demand and adoption of ceramic fiber products across various industries in North America. One key driver is the region's emphasis on industrial innovation and technological advancements. As industries seek more efficient and high-performance materials, ceramic fibers, known for their thermal insulation and high-temperature resistance, become increasingly essential. Applications in sectors such as manufacturing, aerospace, and petrochemicals are likely to contribute to the surge in sales.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.