China PCB Manufacturer Insights: Understanding Production Quality.

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

China PCB Manufacturer Insights: Understanding Production Quality

China's reputation as a global manufacturing hub extends deeply into the electronics industry, making it a top choice for printed circuit board (PCB) production. For businesses looking to partner with a Chinese PCB manufacturer, understanding the nuances of production quality is critical. With countless manufacturers offering competitive pricing, how do you ensure PCB Manufacturers China products meet your specific standards? Let's explore the key factors that define production quality and how to confidently navigate this dynamic market.

What Defines Production Quality in PCB Manufacturing?

When assessing a PCB manufacturer's production quality, it’s important to consider both technical precision and material integrity. A high-quality PCB ensures optimal circuit performance and long-term reliability. Here are some essential indicators of production quality:

• Manufacturing Accuracy

Precision is foundational in PCB production. This includes exact layer alignment, smooth edge finishing, and consistently accurate hole drilling to prevent electrical failure during device operation.

• Material Selection

Top-tier manufacturers source raw materials like copper foil, resin, and fiberglass from trusted suppliers. High-quality materials ensure excellent durability, thermal resistance, and conductivity.

• Inspection and Testing Protocols

Rigorous inspection processes—like automatic optical inspections (AOI) or electrical testing—help manufacturers catch defects before delivery, safeguarding against future product malfunctions.

Understanding the role these elements play will help you pinpoint manufacturers that prioritize industry-leading standards.

Key Features of High-Quality Chinese PCB Manufacturers

For businesses seeking a reliable manufacturing partner, knowing what to look for is invaluable. Trusted Chinese PCB manufacturers typically offer:

1. Certifications and Compliance

Look for ISO certifications (e.g., ISO 9001, 14001), RoHS compliance, and adherence to industry standards like IPC Class 2 or 3. Certifications reflect the manufacturer's commitment to maintaining quality at all stages of production.

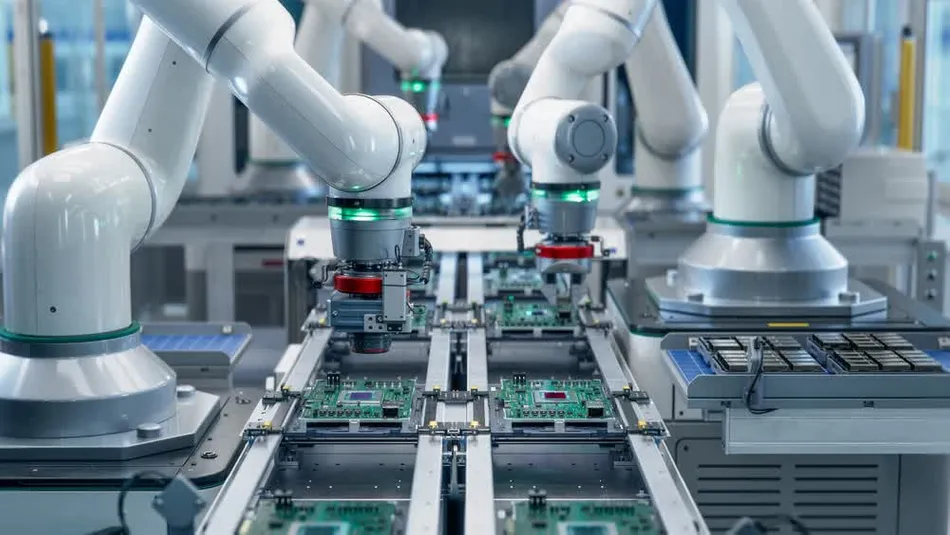

2. Advanced Technology

Leading manufacturers invest in state-of-the-art equipment for automated circuit printing, laser drilling, and error detection. Technology-backed workflows often result in more consistent performance and narrower tolerances.

3. Custom Capabilities

Whether you need multi-layer PCBs, HDI (high-density interconnect) boards, or flex-rigid PCBs, high-quality producers can customize designs to match your project’s specifications without compromising quality.

4. Transparent Communication

Quality manufacturers are upfront about processes, timelines, and costs. They’ll collaborate to understand your design requirements, helping you resolve potential issues before production begins.

5. Global Experience

Does the manufacturer serve international clients? Extensive global experience often translates to familiarity with export logistics, international quality standards, and consistent product reliability.

How to Vet a Chinese PCB Manufacturer for Quality

When partnering with a manufacturer, the following steps can help ensure product quality matches expectations:

• Request Samples

Before committing, ask for product samples to evaluate build quality, surface finish, and electrical capability. This physical evidence helps verify their standards.

• Perform Facility Audits

If possible, visit their production facility. Observing processes firsthand—like soldering, assembly, and testing—provides unmatched clarity about their quality controls.

• Review Reputation and Client Feedback

Look for reviews and case studies from current or past clients, especially those in the same industry. Positive feedback often indicates consistency and reliability.

• Evaluate Customer Support

A manufacturer with dependable customer service actively assists with revisions and troubleshooting. Their willingness to partner at every stage indicates their investment in your success.

• Seek Local Liaisons

Collaborate with a third-party quality control partner in China to assess suppliers if you can’t travel for in-person checks. These experts can help verify certifications and flag any potential production risks.

Emerging Trends Elevating PCB Quality in China

China's PCB sector continues to innovate, integrating cutting-edge technologies designed to improve quality while reducing turnaround times. Here are some trends shaping the industry:

• Smart Manufacturing

The adoption of IoT and AI-driven systems for proactive defect detection is ensuring a more streamlined and precise production process.

• Eco-Friendly Practices

A rising demand for green manufacturing—like lead-free solder and reduced hazardous chemicals—pushes manufacturers to adopt sustainable practices without sacrificing quality.

• Miniaturization and High-Density Designs

Increased global demand for compact electronics inspires manufacturers to excel at creating smaller, more complex PCBs with tighter tolerances.

Why Choose China for PCB Manufacturing?

China has cemented its position as a go-to destination due to its balance of affordability, scalability, and technological advancements. While some assume lower cost equates to lower quality, this stereotype is far from the truth when you work with the right manufacturer. China offers both high-volume production capacity and a robust infrastructure of skilled engineers.

Final Thoughts

Navigating China’s PCB manufacturing landscape requires careful attention to detail, but the rewards are worth the effort. By understanding the metrics of production quality and knowing how to vet potential partners, you’ll set your business up for success in securing high-quality components.

When in doubt, foster strong relationships with your manufacturing partners while consistently monitoring their performance standards. The outcome? Seamless production, reliable PCB quality, and a competitive edge in your market.

Whether you’re scaling a single product line or exploring intricate custom designs, the possibilities in China's PCB sector are enormous—are you ready to explore?

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.