chromate-treated SECC electro galvanized steel sheet

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

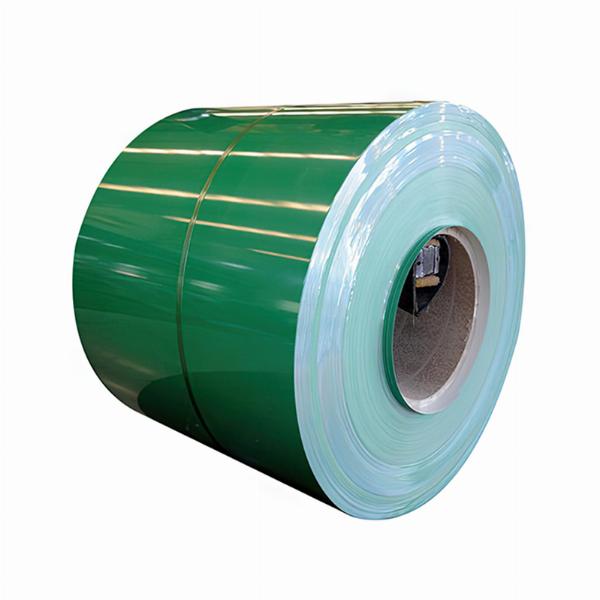

SECC electro galvanized steel sheet is a cold rolled steel sheet with a galvanized surface, which is usually manufactured by continuous electro galvanizing process. It has excellent corrosion resistance and processability, so it has a wide range of applications in several fields, including automotive, construction, home appliances and furniture. The width is 600-1800 mm and the thicknesses is 0.4 -3 mm or according to customers’ requirement.

For refrigerators, SECC electro galvanized steel sheet is mainly used as a shell material. Its surface is smooth, flat and has a metallic luster, which is not only aesthetically pleasing but also effective in resisting corrosion. In addition, SECC electro galvanized steel sheet also has good processing performance, which can meet various complex processing and molding needs in the manufacturing process of refrigerators. Particularly worth mentioning is the chromate treatment, which is a commonly used surface treatment method for steel sheets. Chromate coating can improve the corrosion and abrasion resistance of the steel sheet, and at the same time enhance its adhesion to the paint, making the coating more durable and beautiful. Therefore, the chromate-treated SECC electro galvanized steel sheet not only inherits the excellent corrosion resistance and processing performance of the original steel sheet, but also further improves its surface performance, which makes it more suitable for the manufacture of refrigerators and other household appliances. In addition, the price of SECC electro galvanized steel sheet is relatively economical compared to other high-grade metal materials, making it suitable for mass production and application. This makes it an ideal choice for refrigerator manufacturers in their quest for aesthetically pleasing, durable and cost-effective products.

All in all, used in refrigerator chromate SECC electro galvanized steel coil/sheet is a metal material with excellent corrosion resistance, processability, and economy that meets the high standards required for refrigerator manufacturing and provides a strong guarantee of the quality and performance of refrigerator products. Of course, the quality of our products is unquestionable. We have obtained ISO and SGS international certifications. And our production efficiency is also very high, with a monthly output of about 5000 tons. And single package size is 10X10X10 cm and single gross weight is 0.500 kg. In general, our delivery time is within 20-35 days, and may be delayed if the demand is extremely large or special circumstances occur. For the packaging methods, we choose suitable package and reinforce for various steel products when loading and transport. Usually wooden tray, iron wrapper, waterproof paper. If you have any further questions about this product, please don’t hesitate to contact us.

SECC electro galvanized steel sheet is a cold rolled steel sheet with a galvanized surface, which is usually manufactured by continuous electro galvanizing process. It has excellent corrosion resistance and processability, so it has a wide range of applications in several fields, including automotive, construction, home appliances and furniture. The width is 600-1800 mm and the thicknesses is 0.4 -3 mm or according to customers’ requirement.

For refrigerators, SECC electro galvanized steel sheet is mainly used as a shell material. Its surface is smooth, flat and has a metallic luster, which is not only aesthetically pleasing but also effective in resisting corrosion. In addition, SECC electro galvanized steel sheet also has good processing performance, which can meet various complex processing and molding needs in the manufacturing process of refrigerators. Particularly worth mentioning is the chromate treatment, which is a commonly used surface treatment method for steel sheets. Chromate coating can improve the corrosion and abrasion resistance of the steel sheet, and at the same time enhance its adhesion to the paint, making the coating more durable and beautiful. Therefore, the chromate-treated SECC electro galvanized steel sheet not only inherits the excellent corrosion resistance and processing performance of the original steel sheet, but also further improves its surface performance, which makes it more suitable for the manufacture of refrigerators and other household appliances. In addition, the price of SECC electro galvanized steel sheet is relatively economical compared to other high-grade metal materials, making it suitable for mass production and application. This makes it an ideal choice for refrigerator manufacturers in their quest for aesthetically pleasing, durable and cost-effective products.

All in all, used in refrigerator chromate SECC electro galvanized steel coil/sheet is a metal material with excellent corrosion resistance, processability, and economy that meets the high standards required for refrigerator manufacturing and provides a strong guarantee of the quality and performance of refrigerator products. Of course, the quality of our products is unquestionable. We have obtained ISO and SGS international certifications. And our production efficiency is also very high, with a monthly output of about 5000 tons. And single package size is 10X10X10 cm and single gross weight is 0.500 kg. In general, our delivery time is within 20-35 days, and may be delayed if the demand is extremely large or special circumstances occur. For the packaging methods, we choose suitable package and reinforce for various steel products when loading and transport. Usually wooden tray, iron wrapper, waterproof paper. If you have any further questions about this product, please don’t hesitate to contact us.

SECC electro galvanized steel sheet is a cold rolled steel sheet with a galvanized surface, which is usually manufactured by continuous electro galvanizing process. It has excellent corrosion resistance and processability, so it has a wide range of applications in several fields, including automotive, construction, home appliances and furniture. The width is 600-1800 mm and the thicknesses is 0.4 -3 mm or according to customers’ requirement.

For refrigerators, SECC electro galvanized steel sheet is mainly used as a shell material. Its surface is smooth, flat and has a metallic luster, which is not only aesthetically pleasing but also effective in resisting corrosion. In addition, SECC electro galvanized steel sheet also has good processing performance, which can meet various complex processing and molding needs in the manufacturing process of refrigerators. Particularly worth mentioning is the chromate treatment, which is a commonly used surface treatment method for steel sheets. Chromate coating can improve the corrosion and abrasion resistance of the steel sheet, and at the same time enhance its adhesion to the paint, making the coating more durable and beautiful. Therefore, the chromate-treated SECC electro galvanized steel sheet not only inherits the excellent corrosion resistance and processing performance of the original steel sheet, but also further improves its surface performance, which makes it more suitable for the manufacture of refrigerators and other household appliances. In addition, the price of SECC electro galvanized steel sheet is relatively economical compared to other high-grade metal materials, making it suitable for mass production and application. This makes it an ideal choice for refrigerator manufacturers in their quest for aesthetically pleasing, durable and cost-effective products.

All in all, used in refrigerator chromate SECC electro galvanized steel coil/sheet is a metal material with excellent corrosion resistance, processability, and economy that meets the high standards required for refrigerator manufacturing and provides a strong guarantee of the quality and performance of refrigerator products. Of course, the quality of our products is unquestionable. We have obtained ISO and SGS international certifications. And our production efficiency is also very high, with a monthly output of about 5000 tons. And single package size is 10X10X10 cm and single gross weight is 0.500 kg. In general, our delivery time is within 20-35 days, and may be delayed if the demand is extremely large or special circumstances occur. For the packaging methods, we choose suitable package and reinforce for various steel products when loading and transport. Usually wooden tray, iron wrapper, waterproof paper. If you have any further questions about this product, please don’t hesitate to contact us.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.