Chumillas Technology: Driving Innovation and Development in the Sweden Ceramic Machinery Market

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Introduction:

Chumillas Technology, a leader in the design and manufacturing of equipment for the Sweden Ceramic Machinery Market, is a driving force behind the development and advancement of ceramic machinery. With over 40 years of experience, Chumillas Technology has become synonymous with precision, reliability, and cutting-edge solutions for ceramic production.

As the Sweden ceramic machinery market continues to evolve, the company has been at the forefront of incorporating new technologies, adopting sustainable practices, and offering solutions that address the growing demand for high-quality ceramic products. This article explores how Chumillas Technology is adapting to the dynamic landscape of the Sweden ceramic machinery market through strategic initiatives, emerging innovations, and developments.

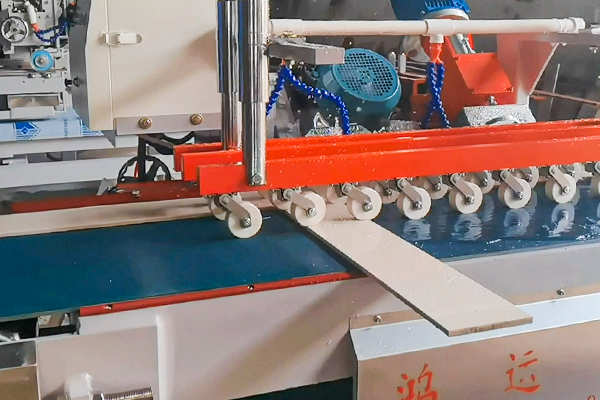

Chumillas Technology: A Global Leader in Ceramic Machinery Chumillas Technology is known for its expertise in producing high-performance machinery that serves various sectors of the ceramic industry, including tile production, sanitary ware, and technical ceramics. The company offers a wide range of machinery solutions, from grinding and mixing equipment to advanced presses, kilns, and drying systems. Their commitment to quality, sustainability, and technological innovation has allowed them to expand their presence globally, including in the Swedish market, where there is a growing demand for advanced ceramic production machinery.

Key Strategies Driving Chumillas Technology’s Success in Sweden

1. Embracing Industry 4.0 and Automation: Chumillas Technology is integrating automation and Industry 4.0 principles into its equipment offerings. The company is focused on producing smart machines capable of real-time data collection, process monitoring, and predictive maintenance. This shift toward automation is crucial for improving productivity, minimizing downtime, and enhancing the overall efficiency of ceramic production. In Sweden, where automation and digitalization are highly valued, Chumillas Technology’s advanced solutions resonate with local manufacturers who aim to reduce labor costs and increase precision.

2. Sustainability and Energy Efficiency: Sustainability is a key theme in the Swedish market, and Chumillas Technology is aligning its developments with Sweden’s commitment to reducing its carbon footprint. The company has been incorporating energy-efficient technologies into its machinery, focusing on reducing energy consumption in ceramic manufacturing processes. With a growing demand for eco-friendly production methods, Swedish ceramic manufacturers are seeking machinery that minimizes environmental impact without compromising on performance. Chumillas Technology’s solutions, such as energy-efficient kilns and low-emission drying systems, are tailored to meet these needs.

3. Customization and Flexibility in Product Design: Another strategy that has allowed Chumillas Technology to succeed in the Swedish ceramic machinery market is its emphasis on customization. Understanding that different ceramic producers have unique production requirements, Chumillas Technology provides tailored machinery solutions. Whether it's the design of specialized presses for intricate tile patterns or customized kilns for high-quality sanitary ware, the company’s ability to adapt its equipment to meet specific customer needs is a significant advantage in the Swedish market.

Emerging Innovations in Ceramic Machinery

1. Additive Manufacturing and 3D Printing: The ceramic industry is increasingly adopting additive manufacturing and 3D printing technologies, which offer new possibilities for design flexibility and product complexity. Chumillas Technology is actively exploring the integration of 3D printing technologies into its machinery lineup. This innovation allows for the production of intricate ceramic designs that would be impossible with traditional manufacturing methods. Swedish ceramic producers, known for their focus on design and aesthetics, have shown keen interest in these capabilities, further pushing the demand for such advanced machinery.

2. Artificial Intelligence and Machine Learning for Process Optimization: Another emerging innovation is the use of artificial intelligence (AI) and machine learning (ML) to optimize ceramic production processes. Chumillas Technology is incorporating AI-driven systems into its machinery to enhance decision-making capabilities. These intelligent systems can analyze data from the production line to optimize parameters such as firing temperatures, drying speeds, and material usage. In Sweden, where precision and quality control are critical in ceramic production, AI-powered machinery is gaining popularity as it provides manufacturers with real-time insights that can lead to improved quality and reduced waste.

3. Advanced Glazing and Surface Treatment Technologies: The Sweden ceramic market places a high premium on the aesthetic qualities of ceramic products, particularly in tile and sanitary ware production. Chumillas Technology has embraced this trend by developing advanced glazing and surface treatment technologies. Their machines allow for the application of intricate glazes with high precision, ensuring a flawless finish. This innovation addresses the growing demand for high-end ceramic products in the Swedish market, where design and quality are critical for success.

Adapting to Sweden’s Demanding Market Environment

The Swedish ceramic machinery market is characterized by a high demand for precision, quality, and sustainability. Chumillas Technology has adapted to these expectations by continuously innovating and offering solutions that not only meet but exceed local market requirements. The company’s approach focuses on understanding the specific needs of Swedish ceramic manufacturers, such as energy efficiency, customization, and technological advancements in automation.

Sweden’s strong environmental regulations and emphasis on sustainability are also factors driving the development of more eco-friendly technologies. Chumillas Technology has positioned itself as a partner for Swedish manufacturers looking to comply with these standards while also maintaining high production standards. The company’s focus on producing machinery that reduces energy consumption and waste has made it an attractive choice for Swedish businesses committed to sustainability.

Conclusion:

Chumillas Technology is making significant strides in the Swedish ceramic machinery market by implementing strategies that embrace the latest technological innovations and sustainability goals. By focusing on automation, energy efficiency, and customization, Chumillas Technology is well-positioned to meet the evolving needs of Swedish ceramic manufacturers.

The company’s commitment to innovation, coupled with its deep industry knowledge, ensures that it will remain a key player in the Swedish ceramic machinery market for years to come. As Sweden continues to lead in sustainability and technological advancements, Chumillas Technology will likely continue to play an essential role in shaping the future of ceramic manufacturing in the region.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.