Clutch Actuator: The Unsung Hero of Automated Gear Shifting

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

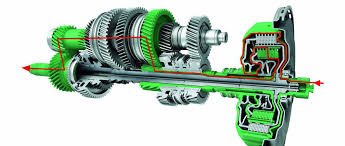

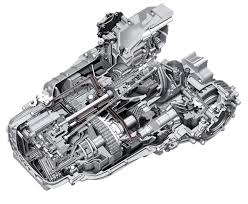

Despite its essential role in modern vehicles with automated manual transmissions (AMT) and semi-automatic gearboxes the clutch actuator remains a frequently neglected component. The clutch actuator takes over the task of engaging and disengaging the clutch that drivers must perform manually in traditional transmissions to enable smoother and more efficient gear changes.

When a clutch actuator begins to fail it causes poor driving performance and jerky gear shifts which can eventually result in transmission failure. By learning about the clutch actuator's operation and maintenance methods drivers can preserve its function and prevent operational issues.

What Exactly Does a Clutch Actuator Do?

The clutch pedal must be pressed by the driver in a manual transmission car to disconnect the clutch which enables smooth gear transitions. The operation of disengaging the clutch in semi-automatic and automated manual transmissions becomes the responsibility of the clutch actuator through electronic or hydraulic means.

The actuator synchronizes with the gearbox control unit and obtains signals from sensors monitoring engine speed along with throttle position and driving conditions. The mechanism operates to engage or disengage the clutch at the perfect instant ensuring seamless gear transitions without requiring driver involvement.

Key Functions of a Clutch Actuator

Automating Clutch Control removes the requirement for a clutch pedal when using AMT and semi-automatic transmission systems.

The system enhances shift timing by coordinating with the vehicle's electronic control unit (ECU) to ensure smooth gear shifts.

The system optimizes gear transitions for smooth operation to lower unnecessary fuel consumption.

The minimisation of driver error through effective clutch control helps to extend the lifespan of the clutch system.

Types of Clutch Actuators

The two main types of clutch actuators operate through different mechanisms.

1. Hydraulic Clutch Actuator

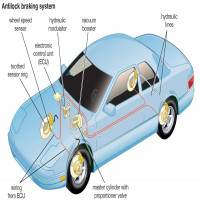

The hydraulic clutch actuator functions by applying hydraulic pressure to control the clutch similar to how braking systems work. The system operates through a master cylinder and slave cylinder while hydraulic fluid transfers the force required for its function.

Pros: The hydraulic clutch actuator offers smooth engagement combined with strong durability and protection against overheating.

Cons: This mechanism needs frequent fluid checks and can develop leaks over time.

2. Electronic Clutch Actuator

Electronic actuators operate clutch movement through integrated sensors and electric motors along with control modules. This device delivers accurate and immediate actions when interpreting signals from the ECU.

Pros: The device operates with minimal energy consumption while delivering quick reactions and needing less room to install.

Cons: The repair costs for this system can become expensive when electronic malfunctions arise.

Signs of a Failing Clutch Actuator

The clutch actuator is designed to function over long periods but eventually experiences problems like other mechanical or electronic parts. Identifying early warning indicators helps to avoid substantial transmission damage.

1. Hard or Delayed Gear Shifts

The actuator may not be working properly when gear shifts take more time than usual or feel rough.

2. Clutch Slipping

Clutch slipping happens when the clutch fails to engage completely which results in power reduction, engine RPM increase and weakened acceleration.

3. Jerky or Unstable Driving

When the clutch actuator malfunctions it leads to erratic gear changes which create a bumpy or unpredictable driving experience.

4. Dashboard Warning Light

The transmission or gearbox warning light activates in many current vehicles when there is a problem with the clutch actuator.

5. Unusual Noises During Gear Shifts

The presence of clicking, grinding and whining sounds during gear changes signifies internal actuator wear or failure.

6. Complete Clutch Failure

A defective clutch actuator may cause the clutch to remain either engaged or disengaged in serious cases which makes it impossible to operate the vehicle.

Common Causes of Clutch Actuator Failure

Different elements contribute to the malfunction of a clutch actuator.

Wear and Tear: With continuous usage, actuator components experience degradation over time.

Hydraulic Leaks: Hydraulic actuators that experience fluid leaks will suffer from reduced pressure and decreased clutch efficiency.

Electrical Malfunctions: Electronic actuators may stop working properly if they suffer from short circuits or have wiring problems or encounter sensor malfunctions.

Overheating: High temperatures can cause damage to actuator components which leads to reduced performance.

Contaminated Fluid: The performance of hydraulic actuators becomes impaired when dirty or degraded fluid leads to blockages within the system.

Steps to Maintain Clutch Actuator Functionality for Extended Performance

The lifespan of a clutch actuator increases with proper maintenance which helps avoid unplanned failures. The following practical steps will maintain your clutch actuator in optimal working condition.

1. Regularly Check Hydraulic Fluid Levels

The performance of hydraulic clutch actuators depends on correct fluid levels which maintain pressure and enable smooth operation.

2. Keep the Transmission System Clean

Actuator function can suffer from interference by dirt and debris so maintaining system cleanliness helps avoid operational problems.

3. Inspect Wiring and Sensors

Electronic actuators require intact sensors and wiring to avoid electrical malfunctions.

4. Avoid Aggressive Driving

The actuator experiences additional stress when the driver performs hard acceleration and sudden braking or uses the clutch excessively. Smooth driving can prolong its lifespan.

5. Schedule Routine Inspections

Routine maintenance helps find potential problems early to prevent major system failures.

Troubleshooting a Faulty Clutch Actuator

When your clutch actuator displays failure symptoms proceed with the following steps:

Step 1: Run a Diagnostic Scan

Check error codes related to the clutch actuator using an OBD-II scanner.

Step 2: Inspect Hydraulic System

For hydraulic actuators ensure there are no leaks present and verify the fluid levels are adequate.

Step 3: Examine Electrical Connections

Verify that wiring connections and function of fuses and sensors remain operational in electronic actuators.

Step 4: Perform a Reset

An ECU reset can recalibrate the clutch actuator to bring its operation back to normal functionality.

Step 5: Seek Professional Help

A qualified mechanic needs to examine the system and determine necessary replacements or repairs if the issue continues.

When to Replace a Clutch Actuator

Replacing a non-repairable clutch actuator remains the optimal solution to restore normal transmission operation. Here’s what the replacement process involves:

The mechanic conducts a diagnosis to confirm that the actuator is causing the problem.

The malfunctioning actuator needs to be detached from the transmission system during the replacement process.

The new actuator is properly installed into its designated position.

The ECU receives a reset to identify the newly installed component.

The system undergoes testing to verify that gear shifts operate smoothly and precisely.

Conclusion

The clutch actuator serves as an essential element in automated manual and semi-automatic transmissions enabling automatic gear transitions without driver involvement. The clutch actuator brings improved convenience and less wear to the clutch but eventually becomes susceptible to failure. You can achieve a reliable driving experience by identifying warning signs early and managing system maintenance effectively while solving problems in a timely manner. Quick diagnosis and repair of a failing clutch actuator can protect your transmission from additional damage and expensive repair fees.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.