Common Issues in Embroidery Digitizing Services and Solutions

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

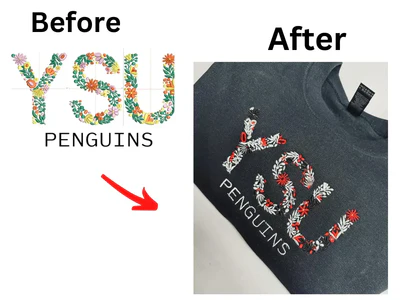

Embroidery digitizing is a critical process that transforms artwork into digital stitch files for embroidery machines, enabling the creation of stunning designs on fabric. While it’s a powerful tool for businesses and creatives, digitizing can encounter challenges that affect the quality of the final product. Understanding these issues and their solutions is essential for achieving professional results. At iDigitize, we specialize in delivering high-quality digitizing solutions to overcome these hurdles. This article explores the most common issues in embroidery digitizing services, their causes, and practical solutions to ensure flawless embroidery.

What is Embroidery Digitizing?

Embroidery digitizing converts designs—logos, patterns, or artwork—into digital stitch files that guide embroidery machines in stitching patterns onto fabric. This process involves defining stitch types, directions, density, and sequence to replicate the design accurately. However, even with advanced technology, digitizing can go wrong without proper expertise, leading to issues that compromise quality. Addressing these challenges ensures your embroidered products meet professional standards.

Common Issues in Embroidery Digitizing

Embroidery digitizing is complex, and several issues can disrupt the process. Below are the most frequent problems encountered and their impacts.

1. Puckering of Fabric

Issue: Puckering occurs when the fabric around the embroidery distorts or wrinkles, creating an uneven surface. This is often caused by excessive stitch density or improper stabilization.

Impact: Puckered fabric looks unprofessional and can ruin the appearance of uniforms, apparel, or merchandise.

Solutions:

-

Use appropriate backing or stabilizer for the fabric type (e.g., tear-away for stable fabrics, cut-away for stretchy materials).

-

Reduce stitch density to minimize tension on the fabric.

-

Adjust underlay stitches to provide a stable base for the design.

-

Ensure proper hooping to keep the fabric taut without stretching.

2. Misaligned or Distorted Designs

Issue: The embroidered design may appear stretched, skewed, or misaligned compared to the original artwork, often due to incorrect pull compensation or improper digitizing settings.

Impact: Distorted designs fail to reflect the intended artwork, leading to brand inconsistency and wasted materials.

Solutions:

-

Apply accurate pull compensation to account for fabric stretch during embroidery.

-

Use high-resolution artwork to ensure precise digitizing.

-

Test the stitch-out on a sample fabric to verify alignment before full production.

-

Work with experienced digitizers who understand fabric behavior.

3. Thread Breaks or Gaps

Issue: Thread breaks during embroidery, leaving gaps or incomplete sections in the design. This can result from excessive stitch density, long stitches, or incorrect tension settings.

Impact: Gaps and breaks create an unfinished look, requiring time-consuming repairs or re-embroidery.

Solutions:

-

Optimize stitch length and density to reduce strain on the thread.

-

Use appropriate needle and thread types for the fabric and design.

-

Incorporate lock stitches to secure thread ends and prevent unraveling.

-

Regularly maintain embroidery machines to ensure proper tension and performance.

4. Poor Color Matching

Issue: The embroidered design’s colors don’t match the original artwork, often due to inaccurate thread selection or lack of color calibration.

Impact: Incorrect colors undermine brand identity, especially for logos, and can lead to customer dissatisfaction.

Solutions:

-

Use Pantone or thread color charts to match threads to the design’s palette.

-

Provide color codes or samples with the artwork for accurate reference.

-

Request a test stitch-out to verify color accuracy before production.

-

Choose high-quality threads that maintain vibrancy after washing.

5. Excessive Stitch Density

Issue: Too many stitches in a small area cause the design to become stiff, bulky, or puckered, often due to poor digitizing planning.

Impact: Overly dense designs are uncomfortable to wear, damage delicate fabrics, and increase production costs.

Solutions:

-

Optimize stitch count to balance detail and fabric compatibility.

-

Use lighter fill stitches or open patterns for large areas to reduce density.

-

Adjust underlay stitches to support the design without adding bulk.

-

Test designs on similar fabrics to ensure comfort and flexibility.

6. Incompatibility with Embroidery Machines

Issue: The digitized file may not work with the client’s embroidery machine due to incorrect file formats or unsupported settings.

Impact: Incompatible files delay production and require additional conversions, disrupting workflows.

Solutions:

-

Provide stitch files in multiple formats (e.g., DST, PES, JEF) to ensure compatibility.

-

Confirm the client’s machine specifications before digitizing.

-

Use industry-standard digitizing software to create universally compatible files.

-

Offer technical support to assist with file setup and machine settings.

Why Professional Digitizing Services are Essential

While DIY digitizing software is available, professional Idigitize services offer expertise and tools to prevent and resolve these issues. Here’s how professionals ensure quality:

-

Experienced Digitizers: Skilled professionals understand stitch types, fabric properties, and machine capabilities, minimizing errors.

-

Advanced Software: Tools like Wilcom or Pulse enable precise stitch mapping and optimization, reducing issues like puckering or thread breaks.

-

Quality Control: Test stitch-outs and rigorous checks catch problems before production, ensuring consistent results.

-

Customer Collaboration: Professionals work closely with clients to understand project needs, offering revisions and guidance to achieve the desired outcome.

Tips for Avoiding Digitizing Issues

To ensure smooth embroidery projects, consider these proactive steps:

-

Submit High-Quality Artwork: Provide clear, high-resolution designs (e.g., vector files like AI or EPS) to enable accurate digitizing.

-

Specify Project Details: Share information about fabric types, machine models, and design placement for tailored stitch files.

-

Request Test Stitch-Outs: Verify the design on a sample fabric to catch issues like puckering or misalignment early.

-

Choose Reputable Providers: Partner with experienced digitizing services with a proven track record of quality and reliability.

-

Communicate Clearly: Provide color codes, brand guidelines, or specific preferences to align the design with your vision.

The Impact of Resolving Digitizing Issues

Addressing common digitizing issues ensures your embroidery projects are professional, durable, and visually stunning. For businesses, this means branded uniforms or merchandise that enhance credibility and customer trust. For individuals, it delivers personalized designs that exceed expectations. By partnering with quality digitizing services, you minimize errors, save time and costs, and achieve results that elevate your embroidery projects.

Conclusion

Embroidery digitizing is a complex process that can encounter challenges like puckering, thread breaks, or poor color matching. However, with the right solutions—such as optimized stitch files, fabric-specific adjustments, and rigorous testing—these issues can be prevented or resolved. Quality digitizing services, like those offered by iDigitize, provide the expertise and tools needed to deliver flawless embroidery. Whether you’re creating uniforms, promotional items, or custom designs, understanding and addressing common digitizing issues ensures your projects shine with precision and professionalism, stitch by stitch.

Frequently Asked Questions (FAQs)

What causes puckering in embroidered designs?

Puckering is caused by excessive stitch density, improper stabilization, or incorrect hooping, which distorts the fabric.

How can I prevent thread breaks during embroidery?

Optimize stitch length and density, use appropriate needles and threads, and maintain proper machine tension to reduce thread breaks.

Why don’t my embroidered colors match my artwork?

Poor color matching results from inaccurate thread selection or lack of color references; providing Pantone codes or samples helps ensure accuracy.

Can digitizing issues be fixed after production starts?

Some issues can be resolved with adjustments, but it’s best to test stitch-outs before production to catch problems early and avoid costly reworks.

Why choose professional digitizing services to avoid issues?

Professional services offer expertise, advanced software, and quality control to prevent common issues, ensuring high-quality, consistent embroidery results.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.