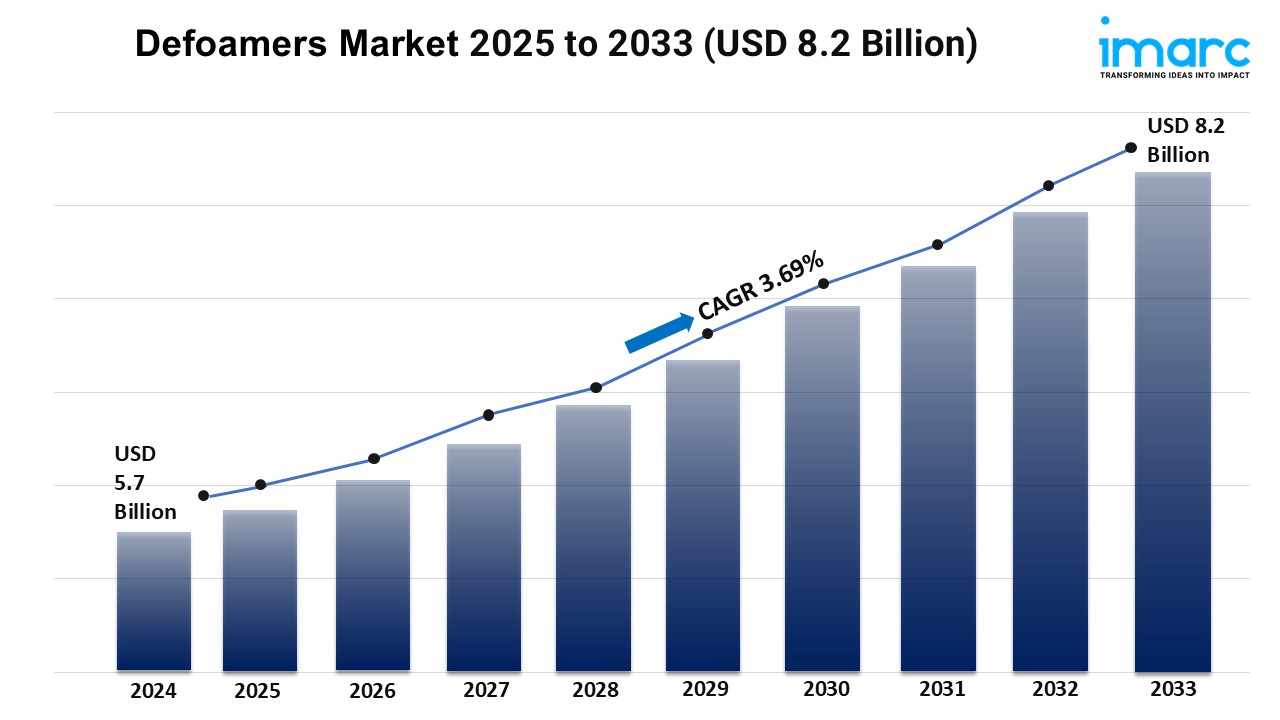

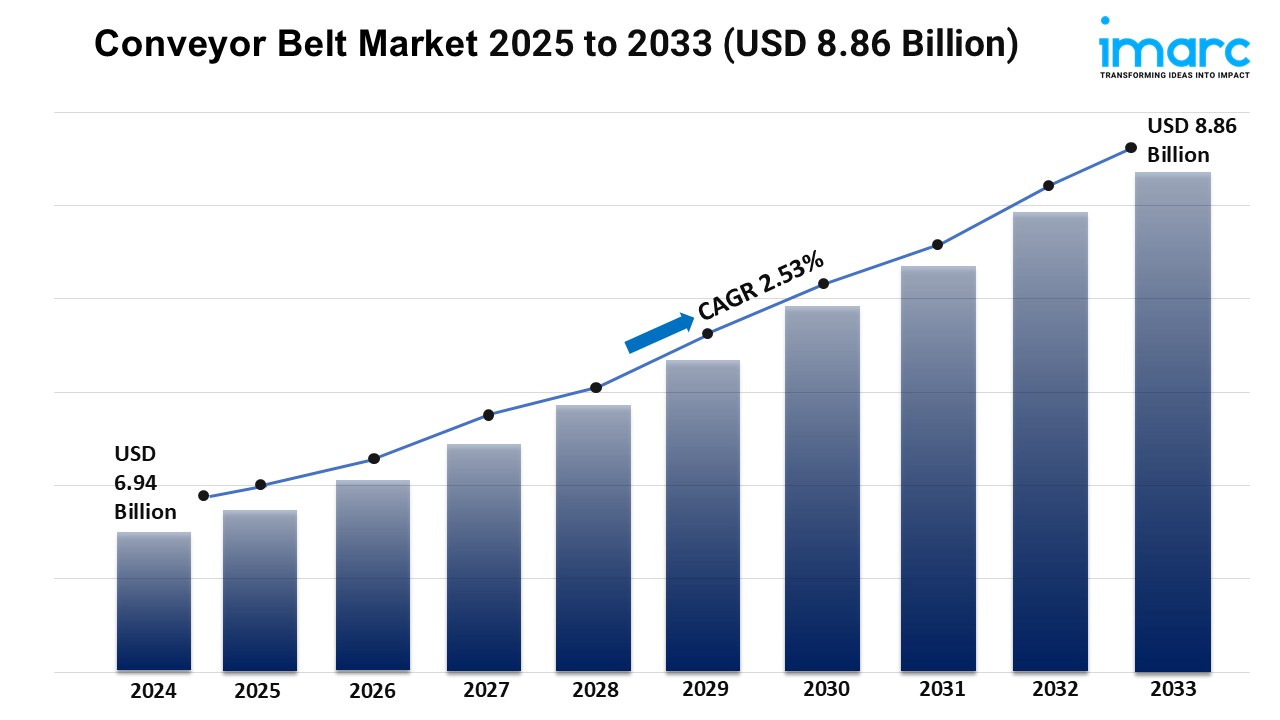

Conveyor Belt Market Growth, Size, Trends, and Forecast 2025-2033

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Market Overview:

The conveyor belt market is experiencing rapid growth, driven by rising drug safety concerns, outsourcing to specialized providers, and ai and automation adoption. According to IMARC Group's latest research publication, ”Conveyor Belt Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033″,The global conveyor belt market size was valued at USD 6.94 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 8.86 Billion by 2033, exhibiting a CAGR of 2.53% during 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Download a sample PDF of this report: https://www.imarcgroup.com/conveyor-belt-market/requestsample

Our report includes:

- Market Dynamics

- Market Trends And Market Outlook

- Competitive Analysis

- Industry Segmentation

- Strategic Recommendations

Conveyor Belt Market: Growth Factors and Key Trends

The conveyor belt market stands as a cornerstone of modern industrial operations, enabling the seamless and efficient transportation of diverse materials and products. From heavy-duty mining applications to precise handling in food processing, conveyor systems are indispensable for optimizing logistics and production workflows. This market's trajectory is influenced by broad economic shifts, technological advancements, and the specific demands of a wide array of end-use industries, making it a dynamic and evolving sector to observe.

Growth Factors

- Escalating Demand for Automation Across Industries:

The pervasive trend of industrial automation is a primary growth driver for the conveyor belt market. Industries globally are increasingly investing in automated solutions to enhance production efficiency, minimize human error, reduce labor costs, and improve overall operational throughput. Conveyor belt systems are fundamental to these automated processes, providing the backbone for continuous material flow in manufacturing assembly lines, packaging facilities, and large-scale distribution centers. For instance, in the automotive sector, conveyor belts are integral to the sequential assembly of vehicles, ensuring components move precisely from one workstation to the next. Similarly, in the pharmaceutical industry, automated conveyor systems guarantee hygienic and precise handling of delicate products, reducing contamination risks and increasing production speeds. This widespread embrace of automation across a multitude of industries directly translates into a sustained and growing demand for reliable and advanced conveyor belt solutions.

- Rapid Expansion of E-commerce and Logistics Sectors:

The explosive growth of the e-commerce sector has significantly propelled the demand for conveyor belts, particularly in warehousing and logistics operations. As online shopping continues to proliferate, there is an unprecedented need for efficient and high-speed order fulfillment processes. Large-scale fulfillment centers, like those operated by major online retailers, rely heavily on intricate networks of conveyor belts to sort, transport, pick, and pack millions of items daily. These systems facilitate rapid throughput, minimize manual handling, and ensure quick delivery times, which are crucial for customer satisfaction in the fast-paced e-commerce environment. Beyond e-commerce, the broader logistics and supply chain industry is also undergoing significant modernization, with investments in automated sorting facilities and distribution hubs that extensively utilize conveyor technology to streamline material flow from inbound receiving to outbound shipping. This continuous need to move vast volumes of diverse goods efficiently underscores the critical role of conveyor belts in the modern economy.

- Growth in the Mining and Heavy Industries:

The robust growth of the mining sector, alongside other heavy industries such as cement, steel, and construction, remains a foundational driver for the conveyor belt market. These industries inherently involve the transportation of vast quantities of bulk materials, often over long distances and in challenging environments. Conveyor belts offer an unmatched solution for efficiently moving ores, coal, aggregates, and other raw materials from extraction sites to processing plants and loading terminals. They provide a continuous, high-capacity, and often more cost-effective and environmentally friendly alternative to traditional truck haulage. For example, large-scale open-pit mines rely on extensive overland conveyor systems to transport excavated materials across rugged terrains, significantly reducing operational costs and carbon emissions compared to a fleet of heavy-duty vehicles. The ongoing global demand for minerals and raw materials, driven by urbanization and infrastructure development, ensures that the need for durable and high-performance conveyor belts in these demanding applications will continue to be a significant growth factor.

Key Trends

- Emergence of Smart and IoT-Enabled Conveyor Systems:

A transformative trend in the conveyor belt market is the integration of smart technologies, particularly the Internet of Things (IoT). Modern conveyor systems are increasingly equipped with sensors and interconnected devices that enable real-time monitoring, predictive maintenance, and data-driven optimization. These intelligent systems can track various parameters such as belt speed, temperature, tension, and wear, alerting operators to potential issues before they escalate into costly breakdowns. For instance, an IoT-enabled conveyor in a manufacturing plant can detect unusual vibrations or temperature spikes, allowing maintenance teams to schedule interventions proactively, thereby minimizing downtime and extending the lifespan of the equipment. This move towards smart, connected conveyor systems enhances operational visibility, improves safety, and allows for more precise control and energy management, representing a significant shift towards Industry 4.0 principles in material handling.

- Increasing Adoption of Lightweight and Durable Materials:

The conveyor belt market is witnessing a strong trend towards the development and adoption of lightweight yet highly durable materials. This innovation is driven by the desire to reduce operational energy consumption, improve belt longevity, and enhance overall system efficiency. While traditional materials like rubber and PVC remain prevalent, there's a growing emphasis on advanced polymers such as polyurethane, polyester, and various composite fabrics. These newer materials offer superior resistance to abrasion, chemicals, and extreme temperatures, making them suitable for a wider range of challenging applications, from food processing with strict hygiene requirements to heavy-duty industrial environments. The reduced weight of these advanced belts also translates to lower energy demands for the conveyor system's motors and less wear on associated components, contributing to lower operating costs and a smaller environmental footprint over the lifetime of the belt.

- Focus on Modular and Customizable Solutions:

The market is increasingly trending towards modular and highly customizable conveyor belt solutions, moving away from rigid, one-size-fits-all designs. Industries now require greater flexibility and adaptability in their material handling systems to respond to evolving production needs, changing product lines, and dynamic facility layouts. Modular conveyor systems, which consist of standardized, interchangeable components, allow businesses to easily reconfigure, expand, or modify their conveyor lines with minimal disruption. This flexibility is invaluable in fast-paced sectors like packaging and logistics, where rapid adjustments to accommodate new product sizes or increased volumes are common. Furthermore, manufacturers are offering extensive customization options, allowing end-users to specify unique belt types, coatings, cleat configurations, and drive systems tailored to their precise operational requirements, ensuring optimal performance for specific materials and processes. This emphasis on modularity and customization provides businesses with agile and future-proof material handling infrastructure.

Leading Companies Operating in the Conveyor Belt Industry:

- Bando Chemical Industries, Ltd.

- Fenner

- Intralox

- Volta Belting Technology Ltd

- Fives

Conveyor Belt Market Report Segmentation:

By Type:

- Medium-Weight Conveyor Belt

- Light-Weight Conveyor Belt

- Heavy-Weight Conveyor Belt

Medium-weight conveyor belt dominates the market due to its versatility, making it suitable for a wide range of industries and applications, from manufacturing to warehousing.

By End-Use:

- Mining and Metallurgy

- Manufacturing

- Chemicals, Oils and Gases

- Aviation

- Others

Mining and metallurgy represented the largest segment due to the increasing reliance of the industry on conveyor belts for transporting ore, minerals, and raw materials efficiently.

Regional Insights:

- North America: (United States, Canada)

- Asia Pacific: (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe: (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America: (Brazil, Mexico, Others)

- Middle East and Africa

Asia Pacific’s dominance in the keyword market is attributed to its rapid industrialization, burgeoning manufacturing sector, and extensive infrastructure development.

Research Methodology:

The report employs a comprehensive research methodology, combining primary and secondary data sources to validate findings. It includes market assessments, surveys, expert opinions, and data triangulation techniques to ensure accuracy and reliability.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.