DAIHEN Corporation's Strategic Role in the Netherlands Wafer Handling Robots Market

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Introduction

The Netherlands Wafer Handling Robots Market is witnessing remarkable growth, fueled by the increasing demand for automation in semiconductor manufacturing. As the country continues to solidify its position as a leader in the global semiconductor industry, the market for wafer handling robots has become an essential component in enhancing production efficiency and minimizing human intervention in the wafer handling process. With projections indicating substantial growth over the next few years, the Netherlands' wafer handling robots market is expected to see a significant surge in value, growing from millions in 2023 to a more than doubled amount by 2030.

This surge in market demand is being driven by several key factors, such as advancements in automation technologies, increased production requirements for semiconductor devices, and the consistent push from the Dutch government and private companies to innovate and modernize their manufacturing capabilities. Among the companies capitalizing on these trends is DAIHEN Corporation, a renowned player in the field of wafer handling systems. With a strong presence across the globe, DAIHEN's strategies, innovations, and developments in the wafer handling robot sector are poised to shape the future of the Netherlands Wafer Handling Robots Market.

Download Free Sample

DAIHEN Corporation: Innovating Wafer Handling Solutions

DAIHEN Corporation has established itself as a leader in the wafer handling robot industry. With a robust revenue stream of USD 188 billion and a dedicated workforce of 4,669 employees in 2023, the company operates across multiple global regions, including Japan, North America, Asia, and other areas.

In May 2022, DAIHEN acquired the German system integrator Femitech, enhancing its system integration capabilities and expanding its range of robot-related products . This acquisition aligns with the company's strategy to provide comprehensive solutions that cater to the evolving needs of customers worldwide.

Inquire Before Buying

Advanced Product Offerings for the Semiconductor Industry

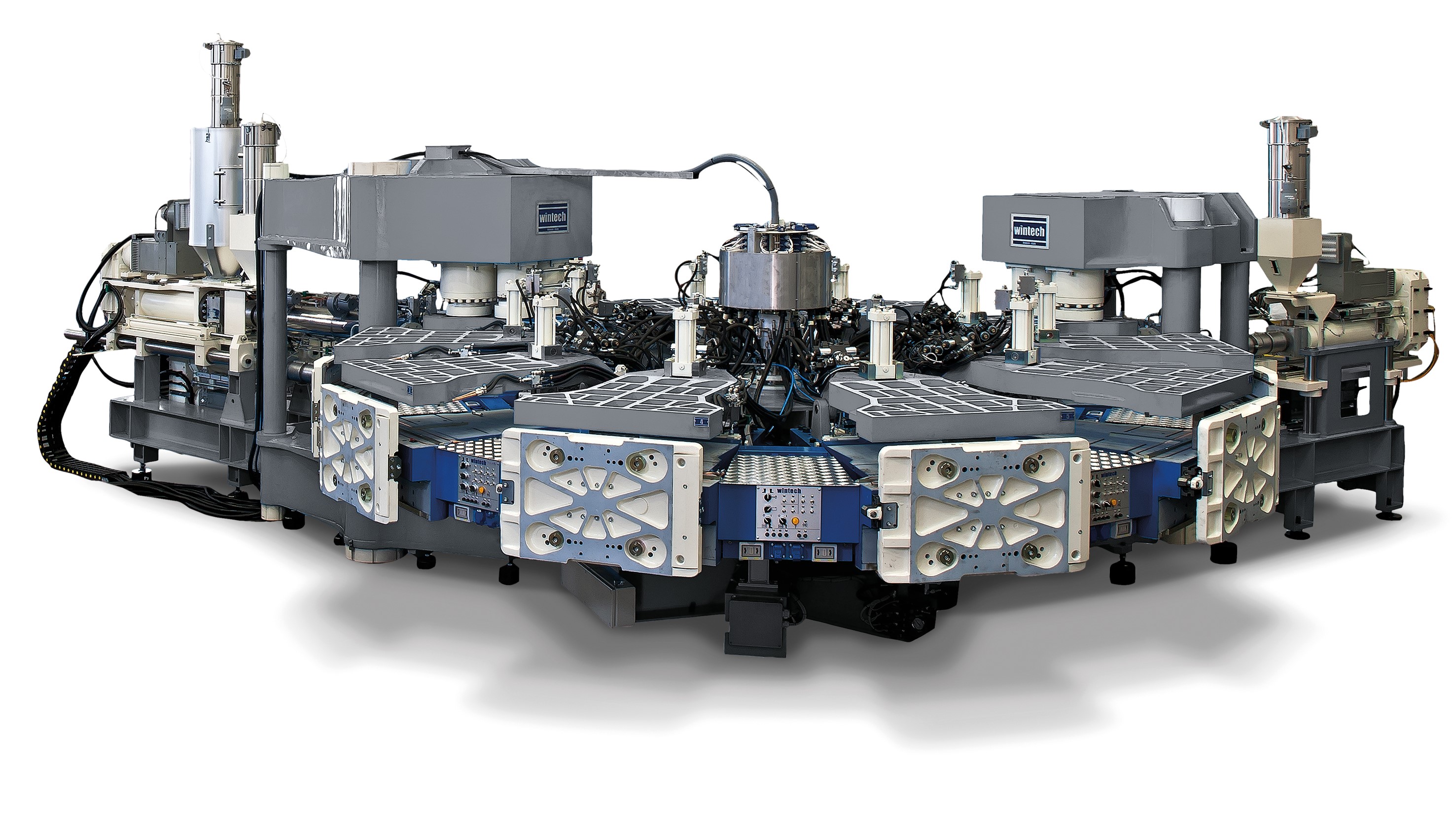

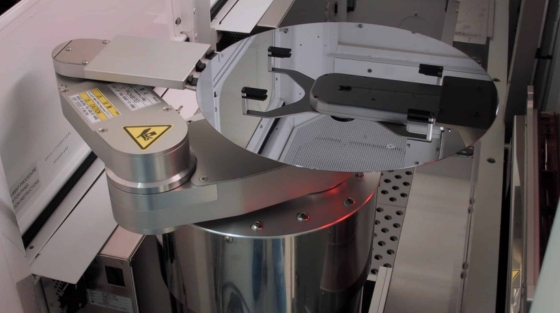

DAIHEN's ACTRANS series of wafer handling robots are designed to meet the stringent requirements of semiconductor manufacturing. These robots are capable of handling wafers up to 300mm and are available in both vacuum and atmospheric environments. Notable models include:

• UT-VSW3000NS: A double-handled vacuum robot with a SCARA arm, contributing to space-saving in vacuum transfer areas

• UT-VDX3000NS: A high-precision vacuum robot for single-arm type equipped with a direct drive motor to significantly reduce vibration.

• UT-VDW3000HS: A high-speed, low-vibration double-arm vacuum robot that achieves a significant improvement in equipment throughput by 650 wafers per hour.

• UT-AXW3000NS: A vertically articulated SCARA arm robot for atmospheric environments, contributing to space-saving in transfer areas.

Strategic Alignment with the Netherlands Market

The Netherlands' commitment to advancing its semiconductor industry presents a promising opportunity for DAIHEN. In May 2023, the Dutch government allocated $1 billion over the next seven years to establish the country as Europe's primary high-tech cluster, focusing on sectors such as agrifood, biomedical production technology, energy, composites, laser-satellite communication, and semiconductors.

This initiative aims to enhance the Netherlands' semiconductor production capabilities, positioning it as a global leader in high-tech innovation and entrepreneurship. DAIHEN's advanced wafer handling solutions are well-suited to support this vision, offering precision, efficiency, and scalability to meet the growing demands of the semiconductor manufacturing sector.

Technological Innovations Driving Market Growth

The integration of advanced technologies such as Artificial Intelligence (AI), computer vision, and the Internet of Things (IoT) into wafer handling robots is revolutionizing the industry. These innovations enable robots to optimize processes, enhance operational efficiency, and facilitate predictive maintenance. AI algorithms play a crucial role in refining robot movements, improving quality control by detecting defects in real-time, and forecasting maintenance needs. Computer vision ensures precise handling of wafers and accurate object recognition, even in complex operational environments. Meanwhile, IoT connectivity allows for real-time monitoring, data exchange, and predictive maintenance, ultimately reducing downtime.

Addressing Market Challenges

Despite the promising growth prospects, the high initial investment required for wafer handling robots poses a significant challenge to market expansion. The costs associated with acquiring, integrating, and maintaining these advanced automation systems can be a financial burden for companies, particularly those with limited budgets. Overcoming this barrier is essential to encourage broader adoption and realize the full potential of the wafer handling robots market.

Conclusion

DAIHEN Corporation's strategic initiatives, innovative product offerings, and alignment with the Netherlands' semiconductor industry objectives position it as a key player in the evolving wafer handling robots market. By leveraging advanced technologies and addressing market challenges, DAIHEN is poised to contribute significantly to the growth and advancement of semiconductor manufacturing in the Netherlands and beyond.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.