How Diaphragm Pumps Boost Performance in Industrial Business Settings

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

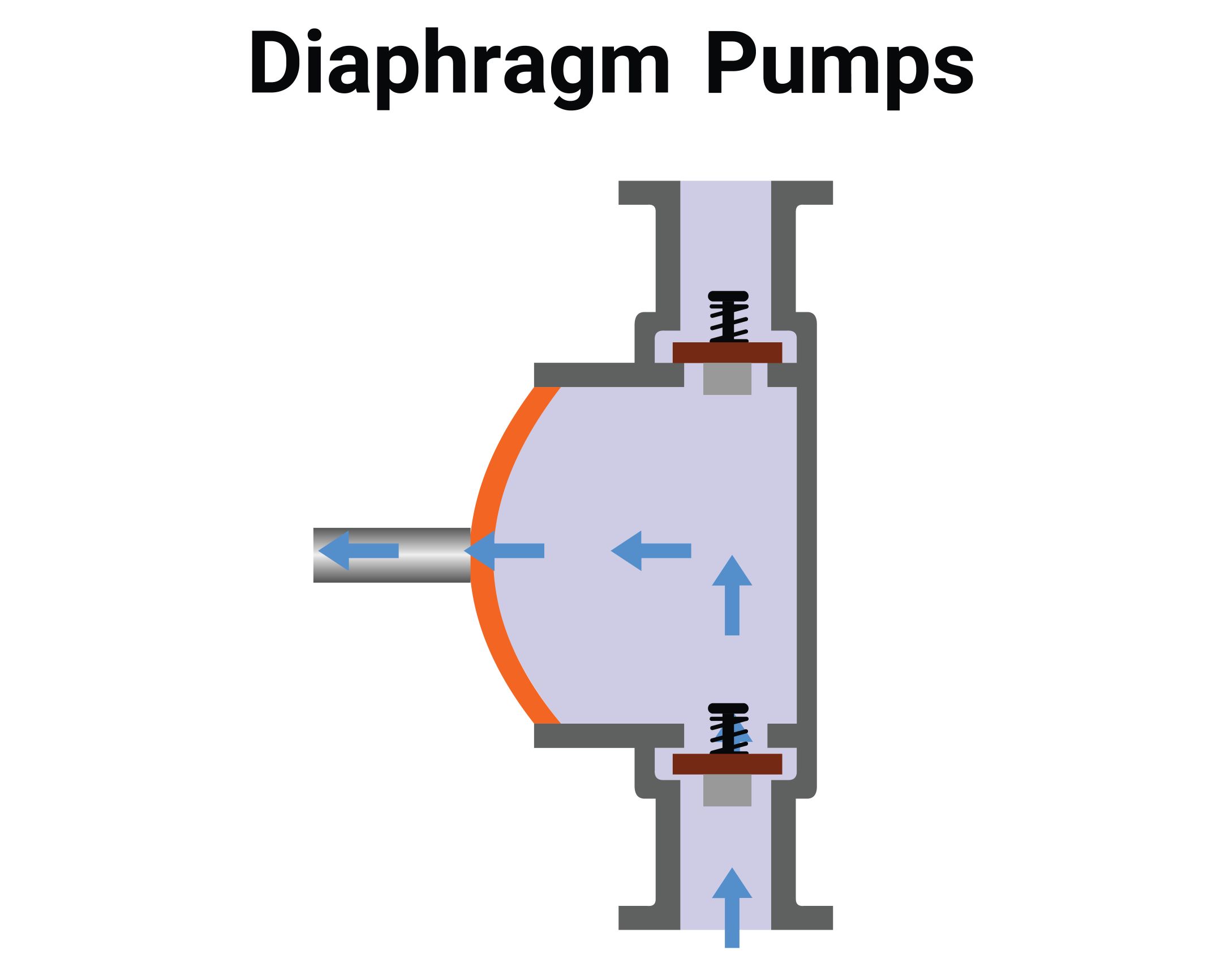

Diaphragm pumps, unique operating mechanisms, and diverse capabilities have emerged as valuable assets in industrial business goals. These pumps utilize a flexible diaphragm that reciprocates back and forth, creating a temporary chamber that draws in and expels fluid.

The versatility, efficiency, and safety features of diaphragm pumps contribute significantly to increased performance across a wide range of industries. Whether it's the ability to handle challenging fluids, reduce downtime, or ensure safe operation in hazardous environments, these pumps offer compelling benefits that translate to improved business productivity and profitability.

The following sections discuss how diaphragm pumps enhance industrial operations and boost business performance.

Versatility in Handling Diverse Fluids

One of the most significant advantages of diaphragm pumps is their exceptional versatility in handling a wide range of fluids. Unlike other pump types that may be limited to specific viscosities or material compatibilities, diaphragm pumps can effectively handle fluids with varying properties.

This includes viscous liquids like adhesives and paints, abrasive slurries containing solids, and even corrosive chemicals. This versatility makes them invaluable in chemical processing, mining, and wastewater treatment industries, where fluids vary significantly in composition and characteristics.

For instance, in the chemical industry, diaphragm pumps can transfer highly corrosive acids and bases without damage, thanks to their chemically resistant diaphragms and valve components. Leading manufacturers like knf.com/en/in offer a wide range of moisture-resistant diaphragm pumps, provide excellent sealing, and prevent contamination. They are designed for challenging chemical applications, ensuring safe and efficient fluid transfer.

Enhanced Efficiency and Productivity

Diaphragm pumps are designed to deliver high flow rates and operational efficiency, contributing to increased productivity in industrial settings. Their ability to generate strong suction and discharge pressures ensures rapid fluid transfer, minimizing processing time and maximizing output.

Moreover, diaphragm pumps are self-priming, meaning they can draw fluid into the pump without manual priming or pre-filling. This eliminates downtime associated with priming procedures, allowing for quicker start-up and continuous operation.

Additionally, unlike other pump types requiring constant fluid flow to prevent overheating, many diaphragm pumps can dry-running without damage. This feature further reduces downtime and maintenance requirements, as the pump can continue to operate even if the fluid supply is temporarily interrupted.

Safety and Reliability in Demanding Environments

Safety is paramount in industrial environments, and diaphragm pumps provide reliable and safe operation, even in demanding conditions. They use excellent sealing to achieve a leak-free design, which ensures that hazardous or sensitive fluids are contained within the pump, preventing spills and contamination. This is crucial in medical devices, chemical processing, and oil and gas, where leaks can have severe environmental and safety consequences.

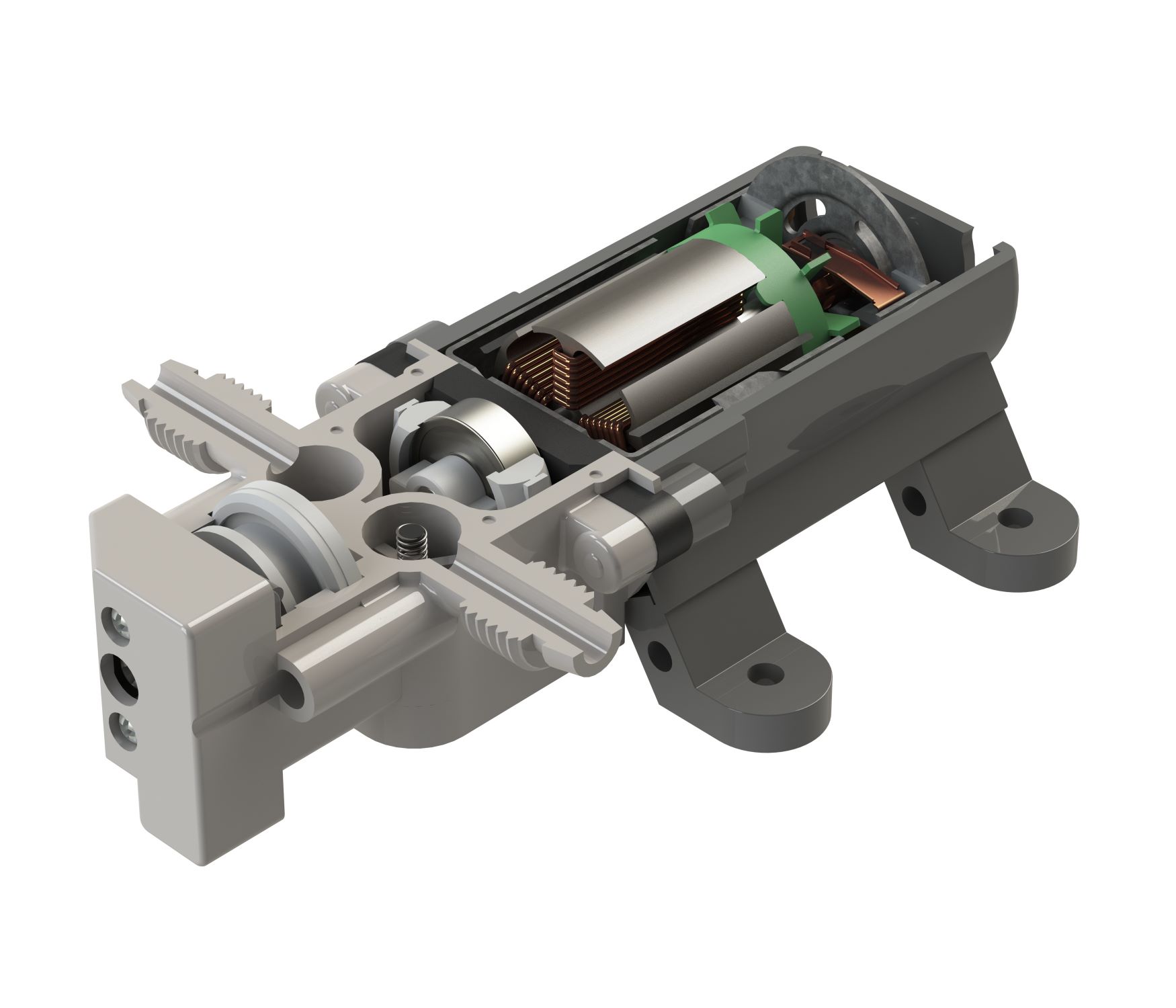

Furthermore, diaphragm pumps are built to withstand harsh conditions, including high temperatures, corrosive environments, and abrasive fluids. Their robust construction, often featuring durable materials like stainless steel or PTFE, ensures longevity and minimizes the risk of breakdowns.

The reduced maintenance needs of diaphragm pumps also contribute to their safety and reliability. With fewer moving parts than other pump types, they are less prone to wear and tear, reducing the frequency of repairs and maintenance interventions. This minimizes the risk of worker exposure to potentially hazardous fluids during maintenance procedures and ensures that the pump remains operational for extended periods.

Cost-Effectiveness and ROI

While the upfront cost of a diaphragm pump might be higher than some other pump types, it's can prove to be more cost-effective in the long-run. Their lower energy consumption, reduced maintenance needs, and increased productivity contribute to significant cost savings over the pump's lifespan.

For example, reduced energy consumption translates to lower electricity bills, which can be a significant expense for industrial businesses. Moreover, the extended lifespan and reduced maintenance requirements of diaphragm pumps minimize repair costs and downtime, further contributing to cost savings.

Adaptability and Customization Options

Diaphragm pumps offer high adaptability and customization, allowing businesses to tailor them to their needs and optimize performance in diverse industrial settings. This has seen their popularity grow, and they are expected to hit a market value of USD$7.6 billion by 2027.

One key aspect of this adaptability is the availability of various diaphragm materials. Different materials offer varying levels of chemical compatibility, temperature resistance, and flexibility, allowing businesses to select the most suitable diaphragm material for their specific fluid and operating conditions.

Furthermore, diaphragm pumps come in various sizes and configurations, from small, portable units to large, industrial-scale pumps. This allows businesses to choose the appropriate pump size and configuration to match their flow rate requirements and application demands.

Conclusion

Diaphragm pumps have proven to be a valuable asset in enhancing performance across various industrial business settings. Their versatility in handling diverse fluids, efficiency, safety features, and cost-effectiveness make them a compelling choice for businesses seeking to optimize their operations. As industries continue to evolve and face new challenges, the adaptability and reliability of diaphragm pumps will play an increasingly important role in driving business success.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.