Zapier Automation – Automate Publishing. Free Your Time!

Zapier Automation – Automate Publishing. Free Your Time!

Driving Efficiency: Exploring the Chain Conveyor Systems Market and Its Global Impact

Written by jigar » Updated on: June 17th, 2025

Introduction

The Chain Conveyor Systems Market addresses a crucial need in material handling across a variety of industries. Chain conveyors, durable machines used for the continuous movement of goods, were developed to streamline manufacturing and logistics processes. The evolution of modern conveyor systems can be traced back to the late 19th century, during the industrial revolution. Pioneers like Richard Sutcliffe and Hymle Goddard played a key role in enhancing these systems to boost productivity, particularly in industries such as mining and automotive assembly. The chain conveyor emerged as an innovation aimed at providing more reliable and robust solutions for heavy loads and challenging operational conditions.

Evolution of the Chain Conveyor Systems Market

Over the years, the Chain Conveyor Systems Market has seen significant transformations. Originally designed as basic mechanisms for transporting bulk materials like coal, today’s chain conveyors are sophisticated systems that are engineered for precision and versatility. Technological advancements have introduced automated, computer-controlled systems that reduce manual labor and optimize production efficiency. The market has expanded into industries like food and beverage, pharmaceuticals, and electronics, where high precision and hygiene standards are crucial. This versatility and the ability to meet the unique requirements of different sectors demonstrate the ongoing innovation in the Chain Conveyor Systems Market.

Why Use Chain Conveyor Systems?

Chain Conveyor Systems have become indispensable in modern manufacturing and distribution. One of their primary advantages is durability and reliability. They are designed to handle a wide variety of products, from light to heavy or bulky items, which makes them suitable for applications that belt conveyors may struggle with. Chain conveyors are also highly versatile, able to be customized with different attachments and configurations to handle specific materials, whether they are bottles, pallets, or automotive parts. Efficiency is another key factor, as chain conveyors facilitate the continuous and rapid movement of goods, which is essential in high-volume production settings. Safety is another advantage. Chain conveyors minimize manual handling, thus reducing the risk of workplace accidents and ensuring safer operations.

Leading Manufacturers in the Chain Conveyor Systems Market

The production of Chain Conveyor Systems is a global industry, with major manufacturers located in key industrial regions. Stuttgart in Germany is recognized for its engineering expertise, and the city is home to some of the most innovative conveyor system manufacturers in the world. Detroit, USA, with its rich automotive history, also plays a significant role in the development and production of heavy-duty conveyor systems. Meanwhile, Shanghai in China, as a major logistics and manufacturing hub, contributes significantly to advancements in conveyor technology. These cities represent the major players in the global Chain Conveyor Systems Market, driving both innovation and production.

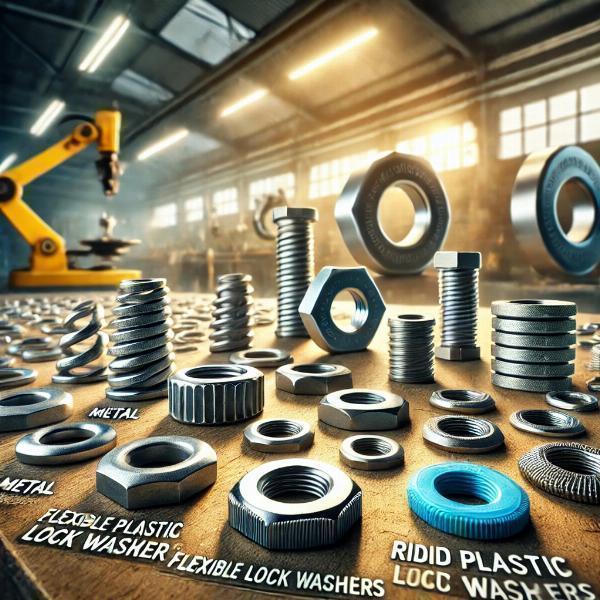

Chain Conveyor Systems Market By Type

In the Chain Conveyor Systems Market, different types of conveyors cater to a range of operational needs. Flexible plastic chain conveyors are typically used in applications that require lightweight products to be transported through tight turns. Rigid plastic chains, on the other hand, are designed for scenarios where higher strength and minimal maintenance are key priorities. Metal chain conveyors are preferred in environments that demand durability, such as heavy-duty industrial settings. In addition, newer materials are being developed to further optimize the weight and efficiency of these systems, ensuring that the market continues to evolve to meet modern demands.

Chain Conveyor Systems Market By Application

Chain conveyors are applied in numerous industries, each with its own specific requirements. In manufacturing, chain conveyors are used to streamline the assembly and handling of products, especially in industries like automotive and electronics, where precision is critical. The food and beverage industry also relies on these systems, particularly for packaging and distribution, where both speed and hygiene are paramount. In the pharmaceutical sector, chain conveyors ensure that sensitive products are handled with care during manufacturing and packaging. Warehousing and distribution centers use chain conveyor systems to streamline storage and the shipment of goods, ensuring efficient management of large inventories. These various applications highlight the importance of chain conveyors in ensuring smooth operations across a range of industries.

Conclusion

The Chain Conveyor Systems Market is expected to experience sustained growth over the next five years. This growth will be fueled by several key factors. First, ongoing technological advancements in automation and materials science will make these systems even more efficient and adaptable to different industrial needs. Second, the expansion of manufacturing and logistics sectors, driven by globalization and increasing trade volumes, will create a greater demand for efficient conveyor systems that can handle high throughput. Lastly, industries are becoming more focused on productivity and workplace safety, and advanced chain conveyor systems provide the necessary solutions to meet these goals.

The future of the Chain Conveyor Systems Market looks promising, driven by its ability to adapt to the changing needs of industries worldwide. As companies continue to innovate and invest in new technologies, the demand for high-quality, efficient chain conveyor systems will grow, ensuring that the market remains a vital component of global manufacturing and distribution networks. With the expansion of industries such as food and beverage, pharmaceuticals, and e-commerce, chain conveyors are set to play an increasingly important role in optimizing operations and driving efficiency in the years to come.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.