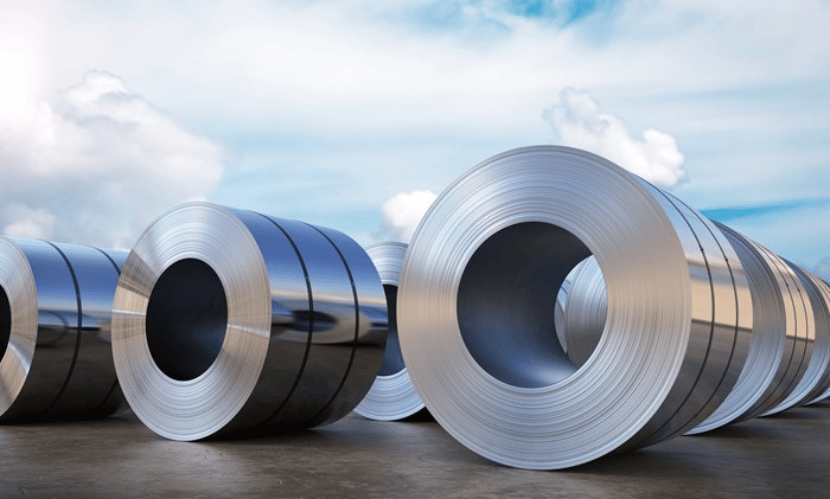

Electrical Steel Market Size, Share, Report & Forecast 2025-2034

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

According to a report by Expert Market Research, the global electrical steel market attained a value of about USD 46.43 billion in 2024. With rising energy demands and increased infrastructure development, the market is projected to grow at a compound annual growth rate (CAGR) of 7.20% between 2025 and 2034. By the end of the forecast period, the global electrical steel market is expected to reach approximately USD 93.06 billion. The industry's growth is fueled by expanding power generation, rising electric vehicle production, and the global push for energy efficiency.

What is Electrical Steel?

Electrical steel, also known as lamination steel or silicon steel, is a specialty steel tailored for its magnetic properties. These steels are primarily used in applications requiring high magnetic permeability and low core loss, making them essential in the production of electric motors, transformers, and generators. By reducing energy loss, electrical steel helps improve energy efficiency across various industries.

Electrical steel is typically categorized into two main types:

- Grain-oriented electrical steel (GOES) – optimized for high efficiency in transformers.

- Non-grain-oriented electrical steel (NGOES) – used in rotating machinery like motors and alternators.

Key Market Drivers

1. Growing Demand for Transformers and Electric Motors

Transformers and electric motors are fundamental to power transmission and industrial automation. With a growing emphasis on upgrading aging grid infrastructure, especially in developing countries, the demand for energy-efficient transformer core materials like grain-oriented electrical steel is accelerating. Electric motors, used in household appliances, HVAC systems, and manufacturing equipment, also contribute significantly to market growth.

2. Surge in Electric Vehicle (EV) Production

The rise of the electric vehicle industry has become a major catalyst for the electrical steel market. EV motors require high-grade, non-grain-oriented electrical steel to ensure performance, reduce losses, and maintain optimal torque. As automakers scale up production of battery electric vehicles (BEVs) and hybrid electric vehicles (HEVs), demand for high-efficiency steel is set to soar.

3. Energy Efficiency Regulations and Sustainable Practices

Governments worldwide are imposing stringent energy efficiency standards to reduce carbon emissions. Transformer and motor manufacturers are now compelled to use electrical steel with lower core losses. Additionally, the move towards renewable energy, such as wind and solar power, requires the installation of transformers and inverters—further driving the use of electrical steel.

4. Smart Grid and Electrification Projects

Electrification of rural and semi-urban areas, especially in Asia-Pacific and Africa, is driving the installation of power distribution systems. Smart grids, designed for real-time energy monitoring and demand-side management, rely on advanced transformers and power distribution units made with electrical steel laminations. As smart grid adoption increases, so will the market for electrical steel.

Market Segmentation

By Product Type

• Grain-Oriented Electrical Steel (GOES)

GOES is engineered with a specific grain structure to reduce hysteresis loss in transformer cores. It is mainly used in large power and distribution transformers. The growing focus on energy-saving and environmental sustainability in power infrastructure is boosting demand for GOES across developed and emerging economies.

• Non-Grain-Oriented Electrical Steel (NGOES)

NGOES is isotropic and used where the direction of magnetic flux constantly changes, such as in electric motors, generators, and alternators. With the increasing adoption of electric mobility and industrial automation, non-grain-oriented steel is expected to witness rapid growth.

By Application

• Transformers

Electrical steel is a core material in the transformer industry due to its low core loss and high magnetic permeability. As utilities and industrial players continue to upgrade their power infrastructure, transformer demand is likely to grow steadily, boosting the electrical steel market.

• Motors

Electric motors rely on NGOES to enhance magnetic performance and reduce energy loss. The global shift toward energy-efficient appliances and electric mobility has made motors one of the most significant applications of electrical steel.

• Inductors and Generators

These components require efficient magnetic materials for effective operation. Electrical steel improves the energy transfer rate and reduces heat losses in these components, making it an indispensable material in power electronics and renewable energy systems.

• EV Components

Traction motors, power converters, and charging infrastructure components in EVs are increasingly using high-grade NGOES. This application segment is projected to expand rapidly with the global push toward electric mobility.

Regional Insights

Asia-Pacific

Asia-Pacific dominates the global electrical steel market due to its strong manufacturing base, rising energy needs, and rapid urbanization. China and India are the leading markets, supported by large-scale grid modernization, electric vehicle policies, and expanding industrial sectors. Japan and South Korea are also key players, especially in supplying NGOES for high-performance EV motors.

North America

The North American market is characterized by aging grid systems and the need for modern, energy-efficient transformers and smart grids. The U.S. government’s infrastructure investment plans are expected to support the domestic demand for electrical steel, particularly for energy-efficient power transformers.

Europe

Europe has a well-established market with a strong emphasis on green energy and energy efficiency. The region is focusing on electrifying transportation and modernizing its power grids to support clean energy targets. The automotive industry in Germany, France, and the UK is also contributing to increased demand for NGOES.

Middle East & Africa

In the Middle East and Africa, increasing investments in power generation and transmission infrastructure are propelling market growth. Governments are focusing on improving electricity access in underserved regions, which will drive the demand for cost-effective and efficient electrical steel.

Latin America

Latin America is seeing moderate growth due to grid expansion projects and industrial development in countries like Brazil and Mexico. Electrical steel suppliers are also expanding their footprint in the region to meet rising demand for electric appliances and infrastructure upgrades.

Key Industry Trends

1. Emphasis on High-Performance Grades

Manufacturers are developing electrical steel grades with reduced core loss, higher permeability, and improved magnetic saturation. These advancements help achieve better motor and transformer performance, contributing to energy conservation and operational efficiency.

2. Vertical Integration by Producers

Leading electrical steel producers are investing in backward integration of raw materials like iron ore and silicon to ensure consistent quality and control over supply chains. This strategic move also helps reduce costs and manage price fluctuations.

3. Rise of Green Steel

Sustainable steel production using hydrogen instead of coke is gaining attention. Several producers are exploring green steel initiatives, aligning with environmental goals and future regulatory compliance.

4. Strategic Mergers and Capacity Expansions

Key players are expanding production capacities, acquiring regional suppliers, and investing in R&D to maintain competitiveness. New production lines for GOES and NGOES are being established to meet the growing global demand, particularly from the electric vehicle sector.

Competitive Landscape

The electrical steel market is moderately consolidated, with global manufacturers competing on the basis of innovation, cost efficiency, and geographic reach. Leading companies include:

- Nippon Steel Corporation

- Baowu Steel Group Corporation Limited

- Tata Steel

- ArcelorMittal

- POSCO

- JFE Steel Corporation

- United States Steel Corporation

- Thyssenkrupp AG

- Voestalpine AG

- AK Steel Holding Corporation

These players focus on developing premium grades of electrical steel and establishing long-term contracts with power equipment manufacturers and EV OEMs.

Future Outlook

With demand surging from renewable energy, electric vehicles, and smart grid development, the global electrical steel market is poised for significant expansion over the next decade. Governments and industries are expected to continue investing in energy-efficient technologies and sustainable infrastructure, creating long-term opportunities for electrical steel suppliers.

Manufacturers that can innovate, maintain quality consistency, and align with ESG standards will stand out in a highly competitive market. The increasing adoption of AI and automation in electrical machinery will also require enhanced materials, further strengthening the demand for premium electrical steel.

Media Contact:

Company Name: Claight Corporation

Email: [email protected]

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: https://www.expertmarketresearch.com

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.