Emerging Innovations and Strategies of Hirata Corporation in the U.S. Wafer Handling Robots Market

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Introduction

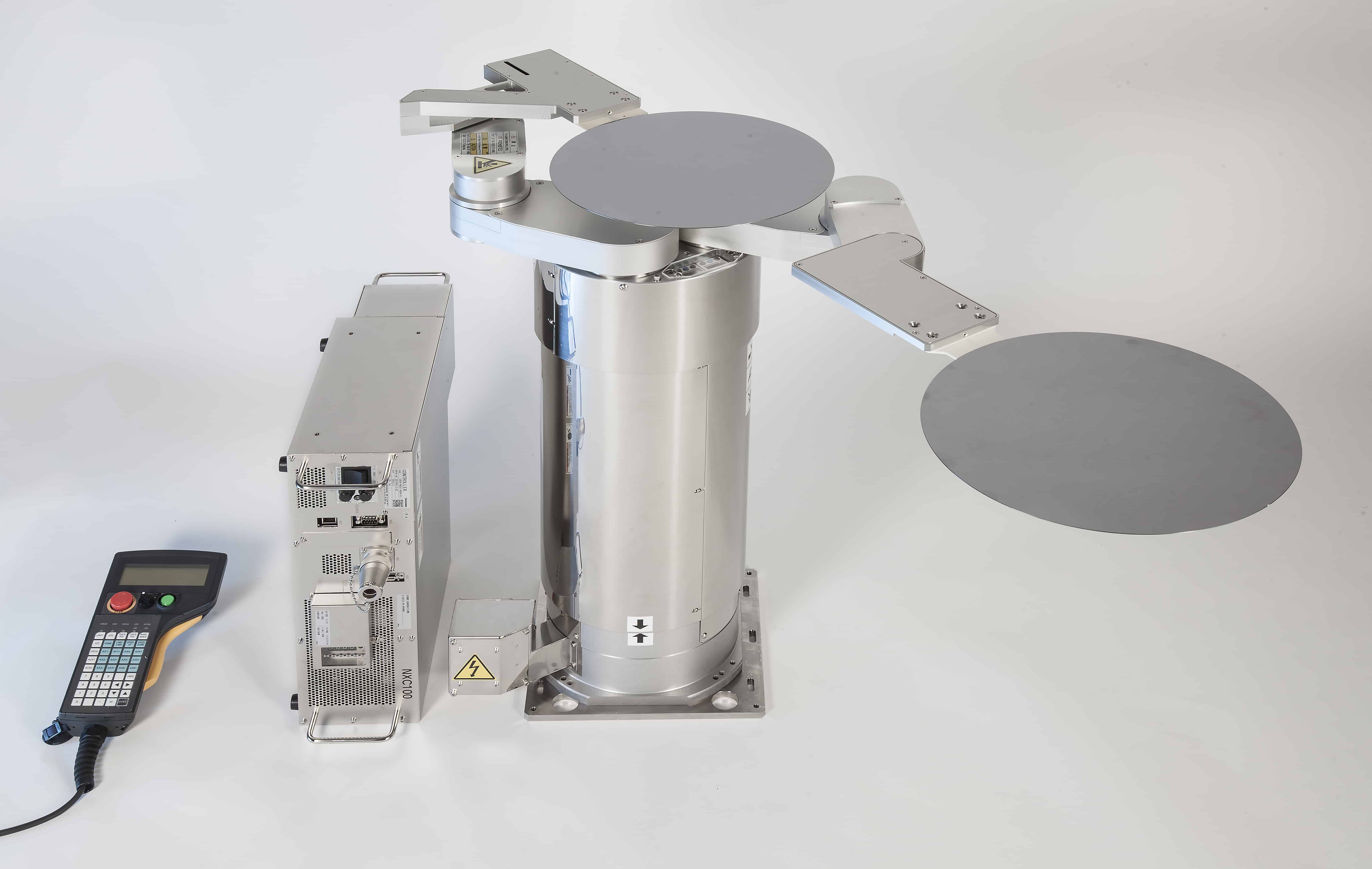

Hirata Corporation, a global leader in automation technology, has been significantly contributing to the advancements in the wafer handling robots sector. Their involvement in the U.S. Wafer Handling Robots Market is marked by a series of strategic moves, innovations, and developments that have enhanced their position in this competitive space. As industries such as semiconductor manufacturing continue to evolve, Hirata’s commitment to innovation and quality positions it as a critical player in meeting the increasing demands for precision and automation. This article delves into the company's strategies and emerging trends in the wafer handling robots market.

Hirata Corporation: A Pioneer in Automation

Founded in 1977, Hirata Corporation is renowned for its cutting-edge automation solutions, particularly in semiconductor manufacturing and wafer handling. With a strong focus on robotics, Hirata has developed high-precision systems that enhance productivity and operational efficiency for various industries, especially in the semiconductor sector.

The company’s deep expertise in wafer handling robots positions it at the forefront of automation in the semiconductor manufacturing process. Wafer handling robots are integral in semiconductor fabrication, providing solutions for material transportation, alignment, and processing. As the demand for smaller and more powerful chips rises, wafer handling robots need to become faster, more precise, and capable of working in environments that require ultra-clean conditions.

Strategic Focus on the U.S. Market

Hirata’s strategy in the U.S. wafer handling robots market has been to continually enhance the adaptability and efficiency of its products. The company has achieved this through an increased focus on customer-specific solutions, offering flexibility in the integration of its systems with existing production lines. By providing tailored solutions that address the specific challenges faced by U.S. semiconductor manufacturers, Hirata has cemented itself as a trusted partner for automation in the wafer handling space.

One of Hirata’s primary strategies involves forming strong local partnerships with U.S.-based semiconductor manufacturers, including those focused on advanced chip production. This collaboration helps Hirata tailor its robots and systems to meet the unique demands of the U.S. market, which is driven by rapid innovation cycles and high-performance standards in semiconductor technology.

Emerging Innovations in Wafer Handling Robotics

Hirata is heavily investing in emerging innovations within the wafer handling robots sector. The company is advancing its technologies to meet the growing need for automation in semiconductor fabrication plants. Some key innovations include:

1. AI and Machine Learning Integration: Hirata’s robots are increasingly incorporating artificial intelligence (AI) and machine learning to optimize wafer handling. These technologies allow robots to learn from past operations, predict system failures, and enhance the overall efficiency of wafer processing.

2. Enhanced Precision and Speed: Wafer handling robots must be able to handle wafers with extreme precision, particularly as wafers become smaller and more sensitive. Hirata’s latest robots offer higher accuracy and faster cycle times, ensuring that semiconductor manufacturers can keep pace with the demand for advanced chips.

3. Cleanroom Compatibility: The semiconductor industry requires environments with strict cleanliness standards. Hirata’s wafer handling robots are designed with advanced materials and sealing mechanisms to function effectively in cleanrooms, maintaining the required sterility and preventing contamination.

4. Modular Designs: One of the key trends in robotics is modularity, and Hirata’s robots reflect this shift. Modular systems enable manufacturers to adapt and scale their operations more easily, providing a flexible solution to meet future production needs.

5. Collaborative Robots (Cobots): As industry trends shift towards greater flexibility and collaboration in manufacturing processes, Hirata is focusing on the development of collaborative robots (cobots). These robots can work alongside human operators, enhancing productivity while maintaining safety and flexibility in wafer handling.

Developments and Achievements in the U.S. Wafer Handling Market

Hirata’s role in the U.S. wafer handling robots market is underscored by its continuous development of new systems and solutions aimed at improving production efficiency and flexibility. Some key developments include:

1. Increased Automation in U.S. Semiconductor Plants: As the demand for semiconductors continues to rise, U.S. semiconductor manufacturers are pushing for higher levels of automation in their plants. Hirata’s wafer handling robots are designed to seamlessly integrate into existing production lines, enabling U.S. companies to meet the growing demand for more advanced chips.

2. Custom Solutions for U.S. Clients: Recognizing the need for tailored solutions, Hirata offers custom configurations to meet the specific needs of U.S. semiconductor producers. These solutions often include unique handling capabilities, speed optimizations, and the ability to work with new materials and wafer sizes.

3. Sustainability Initiatives: As part of a broader global trend toward sustainability, Hirata has made strides in designing energy-efficient systems that reduce the environmental impact of semiconductor production. The company’s robots are built to consume less power, contributing to overall energy savings and sustainability efforts within the semiconductor manufacturing process.

4. Collaborations with Major U.S. Tech Firms: Hirata has established strategic collaborations with leading U.S. tech companies, providing them with innovative wafer handling robots and automation systems. These partnerships have not only strengthened Hirata’s presence in the U.S. market but also allowed the company to stay ahead of emerging technological trends.

Challenges and Future Outlook

Despite its strong position, Hirata faces several challenges in the highly competitive U.S. wafer handling robots market. These challenges include dealing with rapidly changing customer demands, technological advancements, and global supply chain disruptions. However, the company’s emphasis on research and development, coupled with its deep understanding of the semiconductor industry’s needs, positions it well for continued growth.

Looking forward, Hirata’s future in the U.S. wafer handling robots market seems promising. The company’s focus on developing more advanced, intelligent, and modular systems will allow it to adapt to new manufacturing trends and meet the evolving needs of semiconductor producers. With its deep industry expertise and commitment to innovation, Hirata is poised to continue driving the evolution of wafer handling robots in the U.S. market.

Conclusion

Hirata Corporation has firmly established itself as a leader in the U.S. wafer handling robots market by leveraging its innovative solutions and strong strategic initiatives. The company’s ability to provide customized automation solutions, integrate emerging technologies, and form valuable partnerships has enabled it to cater to the needs of semiconductor manufacturers in the U.S. market. As the demand for more advanced and efficient wafer handling solutions continues to grow, Hirata’s commitment to innovation and technological advancement ensures that it will remain at the forefront of this rapidly evolving industry.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.