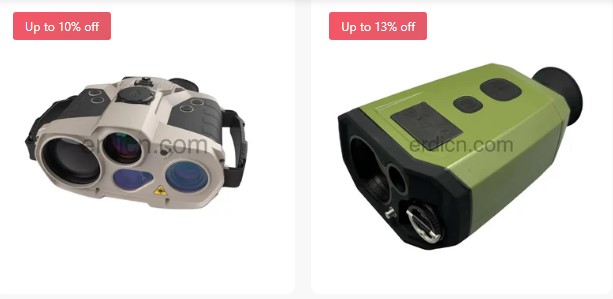

Erdi Laser: Revolutionizing Precision Cutting in Modern Industries

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In the fast-evolving world of manufacturing, precision is the name of the game. Whether it’s automotive, aerospace, electronics, or even artistic endeavors, the demand for accuracy and efficiency has never been greater. Enter Erdi Laser, a cutting-edge solution that has transformed the way industries approach precision cutting. With its advanced technology, versatility, and unmatched efficiency, Erdi Laser is a standout choice for industries worldwide.

What is Erdi Laser?

Erdi Laser is a high-performance laser cutting and engraving technology known for its exceptional accuracy and speed. By harnessing the power of laser beams, Erdi Laser systems can cut through and engrave a wide variety of materials, including metals, plastics, glass, and even organic materials like wood and leather. The technology operates by focusing a high-energy laser beam on a specific point of the material, creating a heat-affected zone that allows for precise cutting or engraving without damaging surrounding areas.

Key Features of Erdi Laser

High Precision and Accuracy

The standout feature of Erdi Laser is its ability to deliver high-precision cuts with minimal tolerance. This makes it ideal for industries where even the slightest error can result in costly setbacks, such as aerospace or medical device manufacturing.

Versatility in Materials

Erdi Laser systems are compatible with a wide range of materials, including stainless steel, aluminum, acrylic, and more. This versatility enables businesses to handle diverse projects with a single machine, reducing the need for multiple cutting tools.

Eco-Friendly Technology

Laser cutting produces less waste compared to traditional cutting methods, as it minimizes material loss. Moreover, Erdi Laser machines often incorporate energy-efficient designs, making them an environmentally conscious choice for businesses aiming to reduce their carbon footprint.

User-Friendly Interface

Despite being a sophisticated piece of technology, Erdi Laser machines are designed with user-friendly interfaces. This ensures that operators can quickly learn to use the machines, thereby increasing productivity and minimizing downtime.

Customization Capabilities

Erdi Laser allows for intricate designs and detailed engravings, making it a favorite among industries such as jewelry making, signage, and custom packaging.

Applications of Erdi Laser in Various Industries

1. Automotive Industry

Erdi Laser plays a critical role in the automotive sector, where precision is paramount. It is used to cut and engrave metal components, ensuring that parts fit together seamlessly. Additionally, it is employed for engraving serial numbers and logos, contributing to both functionality and branding.

2. Electronics Manufacturing

In the electronics industry, where components are often minuscule, Erdi Laser is a game-changer. Its precision ensures that delicate parts such as circuit boards are cut and engraved without damage.

3. Medical Industry

Medical equipment and devices require the highest level of accuracy. Erdi Laser is used to manufacture surgical instruments, implants, and other medical devices with exact specifications, ensuring reliability and safety.

4. Art and Design

For artists and designers, Erdi Laser opens up a world of creative possibilities. Its ability to create intricate patterns and detailed engravings makes it ideal for producing unique art pieces, custom furniture, and decorative items.

5. Aerospace Industry

The aerospace sector relies on Erdi Laser for precision cutting of lightweight yet durable materials like titanium and carbon fiber. This ensures that aircraft components meet stringent safety and performance standards.

Advantages Over Traditional Cutting Methods

Compared to traditional cutting techniques such as mechanical cutting or waterjet cutting, Erdi Laser offers several distinct advantages:

Non-Contact Cutting: The laser beam does not physically touch the material, reducing the risk of contamination and wear on tools.

Faster Processing Times: High-speed lasers enable quicker project completion, boosting overall productivity.

Minimal Material Waste: The precise nature of laser cutting minimizes scrap material, making it more cost-effective.

Enhanced Safety: Modern Erdi Laser systems come equipped with safety features that protect operators from laser exposure.

Future of Erdi Laser Technology

As industries continue to innovate, the demand for advanced laser technology like Erdi Laser is expected to grow. Future advancements may include AI-driven systems for even greater precision, enhanced energy efficiency, and expanded material compatibility. These developments will further solidify Erdi Laser’s position as a leader in the laser cutting industry.

Conclusion

Erdi Laser represents the pinnacle of precision cutting technology, delivering unparalleled accuracy, versatility, and efficiency. From automotive to art, its applications are virtually limitless, making it an indispensable tool for modern industries. By investing in Erdi Laser technology, businesses not only enhance their production capabilities but also gain a competitive edge in their respective fields.

If precision, efficiency, and versatility are what your business needs, Erdi Laser is the solution that delivers on all fronts. With its proven track record and cutting-edge advancements, Erdi Laser is shaping the future of manufacturing one precise cut at a time.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.