Exploring the Benefits of Professional Assembly Detail Drawing Services

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

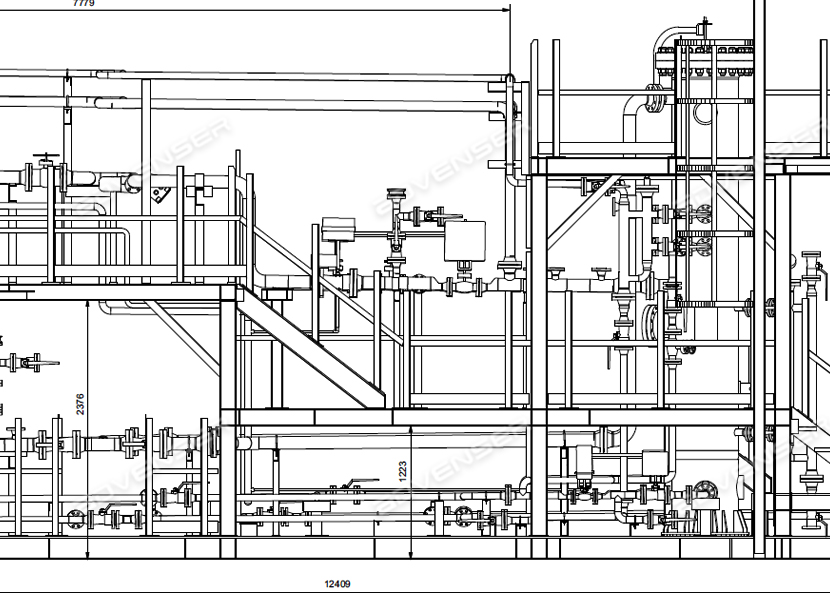

In today's fast-paced manufacturing environment, professional assembly detail drawing services have become indispensable for companies seeking to maintain a competitive edge. These comprehensive technical documents serve as the backbone of product development, bridging the gap between design concepts and physical production. We specialize in creating precise, standardized assembly drawings that significantly enhance manufacturing efficiency, reduce errors, and ultimately lower production costs.

Understanding Assembly Detail Drawings

Assembly detail drawings are comprehensive technical illustrations that provide:

- Complete Dimensional Specifications: Every component is meticulously detailed with dimensions that ensure proper fit and function.

- Exact Placement and Orientation of Parts: Clear indications of how each part should be positioned during assembly.

- Proper Fastening and Joining Methods: Specifications for screws, bolts, welds, or adhesives to be used.

- Material Specifications and Tolerances: Information on the materials used and acceptable tolerances for each component.

- Clear Instructions for Assembly Sequences: Step-by-step guidance on how to assemble the product efficiently.

These drawings serve as the universal language between designers, engineers, and production teams, ensuring everyone works from the same accurate information.

Why Professional Drawing Services Make the Difference

Precision Engineering for Flawless Assembly Our team of certified drafters and engineers creates assembly drawings with exacting precision using advanced CAD software. We go beyond basic dimensions to include:

- Critical Tolerance Analysis: Ensuring that parts fit together correctly under various conditions (+/- 0.005" standard).

- Surface Finish Requirements: Specifying the necessary surface treatments to enhance durability and aesthetics.

- Heat Treatment Specifications: Detailing any heat treatment processes required for specific materials.

- Protective Coating Instructions: Guidelines for coatings that prevent corrosion or wear.

This level of detail ensures components fit together perfectly the first time, eliminating costly rework.

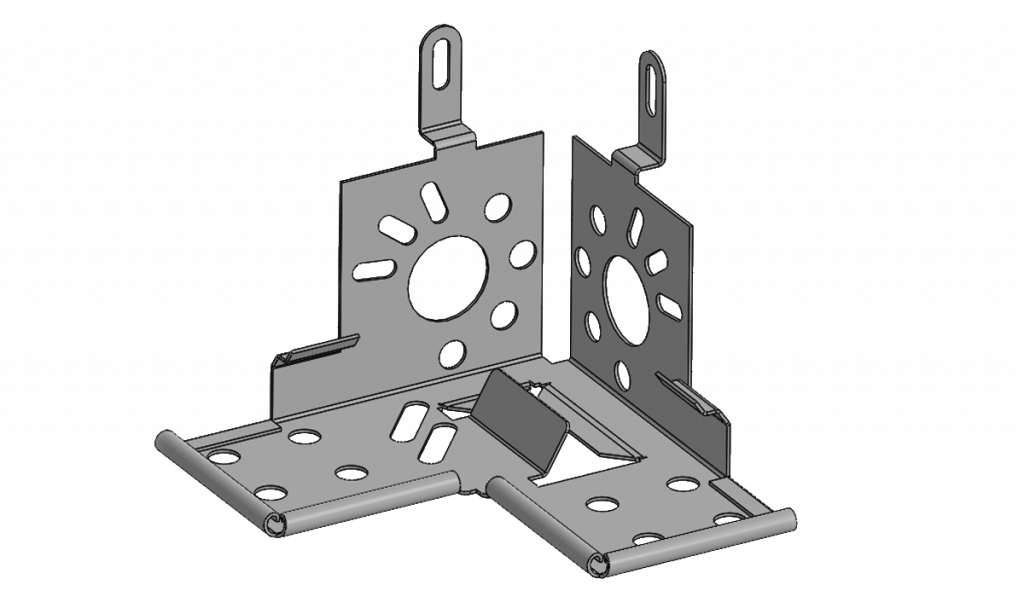

3D Visualization for Proactive Problem Solving Through our advanced 3D modeling capabilities, we can:

- Create Exploded Views: Showing all components in relation to each other, making it easier to understand assembly.

- Generate Animated Assembly Sequences: Visualizing the assembly process to identify potential issues.

- Perform Digital Interference Checking: Ensuring that parts do not conflict during assembly.

- Simulate Maintenance and Disassembly Procedures: Providing insights into how the product can be serviced in the future.

These visual tools help identify potential issues before manufacturing begins, saving time and resources.

Industry-Specific Expertise We customize our approach based on your sector:

- Automotive: Emphasizing vibration resistance and thermal expansion factors to ensure reliability.

- Aerospace: Focusing on lightweighting and stress analysis to meet stringent safety standards.

- Medical Devices: Prioritizing cleanability and biocompatibility to comply with health regulations.

- Industrial Equipment: Ensuring durability under heavy loads and harsh conditions.

Our specialized knowledge allows us to address the unique challenges of each industry effectively.

Key Benefits for Manufacturers

Reduced Production Costs

- 30-50% Fewer Assembly Errors: Accurate drawings lead to fewer mistakes during assembly.

- 25% Faster Assembly Times: Streamlined processes result in quicker turnaround.

- 40% Less Material Waste: Precise specifications minimize excess material usage.

- Elimination of Costly Prototyping Iterations: By getting it right the first time, you save on additional labor and material costs.

Enhanced Quality Control

- Standardized Inspection References: Clear criteria for quality assurance teams to follow.

- Visual Guides for Quality Assurance: Easy-to-understand drawings that help maintain high standards.

- Consistent Documentation for Audits: Well-documented processes that facilitate compliance checks.

Improved Supply Chain Coordination

- Precise Specifications for Vendors: Clear requirements that help suppliers deliver the right materials.

- Standardized Part Numbering: Simplifying inventory management and tracking.

- Clear Packaging and Handling Instructions: Ensuring that parts arrive in good condition.

- Accurate Bill of Materials (BOM): Comprehensive lists that prevent shortages or overages.

Regulatory Compliance Assurance

- Documentation for ISO 9001 Compliance: Ensuring that all processes meet international quality standards.

- Traceability Records: Keeping track of materials and processes for accountability.

- Material Certifications: Providing proof that materials meet required specifications.

- Safety Factor Calculations: Ensuring that products are safe for use under expected conditions.

Knowledge Preservatio

- Detailed Assembly Records for Future Production Runs: Creating a repository of knowledge that can be referenced later.

- Training Materials for New Employees: Simplifying onboarding processes with clear documentation.

- Reference Documents for Product Improvements: Allowing for continuous enhancement of designs.

- Historical Documentation for Warranty Claims: Providing evidence in case of disputes.

Our Advanced Technical Capabilities

We leverage the latest technologies to deliver superior results:

- Parametric Modeling: Allows for quick design iterations and adjustments based on client feedback.

- GD&T Implementation: Ensures functional fit regardless of manufacturing variations, enhancing quality.

- PLM Integration: Maintains version control across global teams, ensuring everyone is working with the latest information.

- Augmented Reality Overlays: Provides assembly guidance on the shop floor, improving efficiency and accuracy.

Case Study: Automotive Component Manufacturer

- Reduced Assembly Time by 35%: Streamlined processes led to faster production.

- Decreased Warranty Claims by 62%: Improved quality control measures resulted in fewer defects.

- Improved First-Time Quality to 99.8%: Accurate drawings ensured that parts fit correctly on the first attempt.

- Standardized Drawings Across 14 Global Facilities: Consistency in documentation improved communication and efficiency.

Conclusion: The Smart Choice for Manufacturing Excellence

Professional assembly detail drawing services represent a strategic investment that pays dividends throughout the product lifecycle. By partnering with our experienced team, manufacturers gain:

- Faster Time-to-Market: Accelerated production processes lead to quicker product launches.

- Lower Production Costs: Reduced errors and waste translate to significant savings.

- Higher Product Quality: Enhanced accuracy and quality control measures ensure superior products.

- Reduced Warranty Exposure: Fewer defects lead to lower warranty claims and improved customer satisfaction.

- Improved Supplier Coordination: Clear specifications facilitate better communication with suppliers.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.