Exploring the Encoder Market: Trends, Growth, and Future Forecast (2024-2032)

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

The global encoder market size attained a value of nearly USD 2.42 billion in 2023. The market is further expected to grow in the forecast period of 2024-2032 at a Compound Annual Growth Rate (CAGR) of 8%, reaching nearly USD 4.83 billion by 2032. This growth is fueled by the increasing demand for automation, precision control, and technological advancements across various industries. Encoders, essential components in motion control systems, are gaining widespread use in industries ranging from automotive to pharmaceuticals, industrial automation, and consumer electronics. In this blog post, we’ll delve into the key trends, technologies, end-use applications, and regional dynamics driving the global encoder market’s expansion.

Market Overview: Understanding Encoders

At its core, an encoder is a device that converts mechanical motion into an electrical signal that can be interpreted by a machine or control system. Encoders are essential in applications where precise position, speed, or motion data is required. They are typically used in automation systems, robotics, elevators, CNC machines, and a variety of consumer and industrial applications.

Encoders are primarily categorized into two types: rotary and linear. The market for encoders can be segmented further by the type of technology used (optical, magnetic, photoelectric, and others) and by their end-use applications, which span a wide range of industries such as automotive, electronics, industrial automation, pharmaceuticals, and more.

Encoder Market by Type

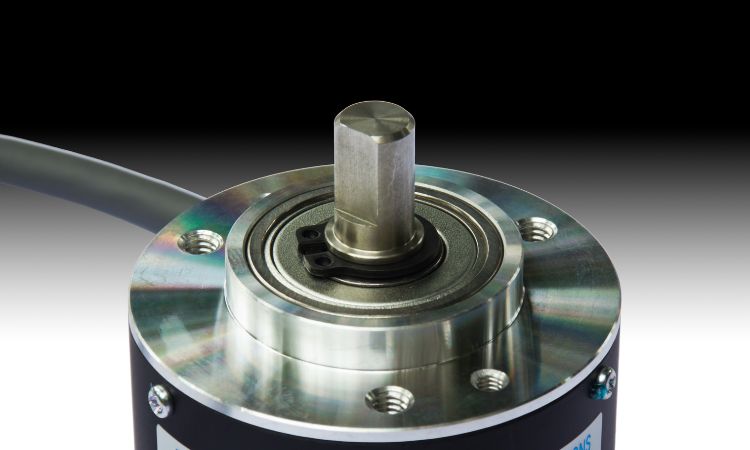

A. Rotary Encoders

Rotary encoders are among the most widely used types of encoders in the market. They measure the rotation of a shaft and convert it into a digital signal. These encoders are crucial in applications where rotational position or motion is needed, such as in motors, robotic arms, and industrial machinery.

In industries like automotive and robotics, rotary encoders are indispensable. For example, in automotive systems, rotary encoders are used for precise control of steering and engine components. The growth of the automotive sector, especially with the increasing focus on electric vehicles (EVs) and autonomous driving technologies, is expected to drive the demand for rotary encoders during the forecast period.

B. Linear Encoders

Linear encoders are designed to measure the position of an object in a straight line, offering extremely high precision. These encoders are widely used in applications requiring linear motion detection, such as in CNC machines, printing presses, and measuring systems.

The market for linear encoders is expected to grow significantly, especially in precision industries like electronics, textiles, and printing machinery. As manufacturing becomes more digitized and automated, the need for accurate position control is increasing, making linear encoders a key technology in these sectors.

Encoder Market by Technology

Encoders can also be classified by the technology they use to detect motion. The primary technologies include optical, magnetic, and photoelectric encoders.

A. Optical Encoders

Optical encoders work by using light to detect motion, offering high resolution and accuracy. These encoders are commonly used in environments that demand high precision and speed, such as in robotics, industrial automation, and aerospace.

Optical encoders are typically more expensive than other types due to their high performance, but their demand is expected to remain strong, particularly as industries like robotics and automation continue to evolve. Technological advancements, such as improvements in optical sensors and miniaturization, are also expected to drive the growth of this segment.

B. Magnetic Encoders

Magnetic encoders use magnetic fields to detect motion and position. These encoders are more durable than optical encoders and perform better in harsh environments, where dust, dirt, and moisture are common.

Magnetic encoders are expected to witness significant growth in applications requiring robust performance and durability, such as in automotive, industrial automation, and material handling equipment. Their resistance to environmental conditions and lower cost compared to optical encoders make them an attractive option for many industries.

C. Photoelectric Encoders

Photoelectric encoders operate similarly to optical encoders but use light interruption or reflection to measure motion. These encoders are particularly useful in applications requiring high resolution and non-contact measurement.

The demand for photoelectric encoders is expected to grow in industries such as printing and packaging, where precision and reliability are critical.

D. Other Technologies

In addition to the main encoder technologies, there are niche applications for other types of encoders, such as capacitive and inductive encoders. These are typically used in specialized environments where traditional technologies may not be suitable.

Encoder Market by End-Use Industry

A. Automotive

Encoders play a pivotal role in the automotive industry, particularly in the control of electric motors, actuators, and steering systems. With the rise of electric vehicles (EVs) and autonomous vehicles, the demand for precise control systems is growing, which in turn boosts the need for encoders.

Rotary encoders, in particular, are extensively used in automotive applications, from controlling the position of windows and seats to providing feedback in advanced driver-assistance systems (ADAS). As the automotive industry continues to embrace innovation, the encoder market in this sector is expected to witness strong growth.

B. Electronics

Encoders are widely used in electronics manufacturing, particularly in automated assembly lines, testing equipment, and robotics. With the growing trend of miniaturization and demand for higher precision in electronic components, the market for encoders in the electronics sector is expanding.

In consumer electronics, encoders are also used in input devices such as computer mice, joysticks, and rotary dials.

C. Industrial Automation

The industrial automation sector is one of the largest end-users of encoders. Encoders are used to monitor and control the motion of machinery and robotic systems in factories and warehouses. As industries continue to adopt Industry 4.0 technologies and automate their processes, the demand for encoders will grow.

Encoders ensure the smooth functioning of assembly lines, increase productivity, and improve system efficiency, making them an integral part of modern industrial operations.

D. Pharmaceuticals and Other Sectors

Encoders are increasingly being used in pharmaceutical manufacturing for quality control and process automation. They are also used in industries like textiles, printing, packaging, and food processing, where precise motion control is crucial.

Regional Analysis

The encoder market’s growth trajectory varies by region, with North America, Europe, and Asia-Pacific being the major players.

A. North America

North America holds a significant share of the encoder market due to the presence of major industrial automation and electronics companies. The growing adoption of robotics and smart manufacturing technologies is a key driver of encoder demand in this region.

B. Europe and Asia-Pacific

Europe and Asia-Pacific are also witnessing substantial growth in the encoder market. In Europe, advancements in manufacturing technologies and the rise of the automotive and aerospace industries are contributing to demand. Asia-Pacific, particularly countries like China and Japan, is seeing rapid growth driven by industrial automation and the expansion of the electronics sector.

Future Outlook and Market Forecast (2024-2032)

The global encoder market is poised for robust growth, with a forecasted CAGR of 8% from 2024 to 2032. Technological advancements, increasing automation, and the growing need for precision control in various industries will drive this expansion.

Emerging trends such as the integration of encoders with IoT devices, AI-powered motion control systems, and the adoption of encoders in smart manufacturing will continue to shape the market’s future.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.