Exploring the Versatility of Polycarbonate: Applications, Manufacturing, and Advantages of Polycarbonate (2023-2034)

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Polycarbonate is a common polymer which finds applications from automotive to consumer goods. In this blog, we'll dive into the fascinating world of polycarbonates. We'll explore its unique properties, its manufacturing process, and its range of applications that make it popular in the world of polymers. The global Polycarbonate market is likely to flourish at a moderate CAGR of 4.32% by the year 2034.

Here are some of the main topics we'll cover in this blog:

The Properties: Get to know the details of polycarbonate's remarkable properties like toughness, clarity, and heat resistance.

Applications: Explore the applications of polycarbonate, from lifesaving medical devices to everyday consumer products.

Introduction

Polycarbonate (PC) stands out as a high-performance thermoplastic polymer. Its molecular structure comprises organic functional groups connected by carbonate groups (–O–(C=O)–O–), granting it a distinctive array of properties. Due to its remarkable compatibility with certain polymers, polycarbonate finds extensive use in blends like PC/ABS, PC/PET, and PC/PMMA. This versatile material is employed in various applications, including compact discs, safety helmets, bulletproof glass, car headlamp lenses, baby feeding bottles, roofing, glazing, and more. With its exceptional toughness, transparency, and thermoplastic nature, polycarbonate remains a sought-after choice across industries, offering a balance of strength, durability, and optical clarity. Its ability to withstand impact, coupled with its transparent quality, renders it indispensable in safety-critical applications like protective gear and automotive components. Moreover, its versatility allows for diverse applications, ranging from consumer products to architectural solutions. Its properties include:

Transparency: PC boasts high transparency, facilitating superior light transmission. It is commonly utilized in applications necessitating optical clarity, like eyeglass lenses and transparent protective shields.

Impact resistance: A standout characteristic of PC is its outstanding resistance to impact. It is virtually indestructible, making it ideal for safety-critical applications such as bulletproof glass, safety goggles, and automotive headlight lenses.

Heat resistance: PC can endure high temperatures without melting or distorting. Its elevated glass transition temperature renders it suitable for applications requiring exposure to heat, such as microwave-safe cookware and LED light covers.

Lightweight: Despite its strength, PC is relatively lightweight. This property makes it favored for weight reduction in industries such as aerospace and automotive.

UV resistance: PC exhibits good resistance to ultraviolet (UV) radiation, making it suitable for applications like greenhouse panels or protective covers for outdoor equipment.

Manufacturing Process

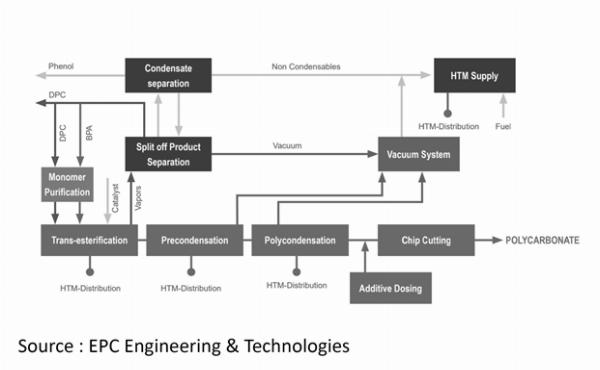

VARIPLANT Process is the main process used to produce Polycarbonate. This process initiates Bisphenol A (BPA) and Diphenyl carbonate (DPC) melting which are then introduced into a raw material melt mixing tank. To ensure high-purity monomer essential for polycarbonate production, purification methods like filtration and impurity removal through stripping are applied. The pre-heated raw materials are then delivered in liquid form into the transesterification reactor. During the initial reaction phase, the raw material melt is combined with catalysts and heated to the specified transesterification temperature, adjusting a specific pre-conversion rate. As monomer and polymer chains develop, phenol begins to separate. Upon completion of transesterification, the produced oligomers are continuously discharged and directed to the prepolycondensation I reactor for the subsequent reaction phase.

By employing elevated temperatures and reduced vacuum conditions, mid-size chain length molecules are formed. Following the prepolycondensation I reactor (PP I), and depending on the plant's production rate design, the system can be configured with one, two, or three polycondensation lines in parallel. This allows for the simultaneous production of up to three distinct product grades. The product from PP I is then transferred to the prepolycondensation II reactor for further chain growth, and subsequently to the final polycondensation reactors. The final polycondensation reactor plays a crucial role in achieving the desired polymer chain length, thereby attaining the targeted properties of the Polycarbonate. Both the horizontal prepolycondensation II stage and the final reactor are equipped with a disc-ring agitator, ensuring significant surface area for efficient mass transfer and chemical reactions.

Applications of Polycarbonate

Electricals & Electronics

Polycarbonate and their blends find application in various appliances like refrigerators, air conditioners, coffee machines, and washing machines. Their utilization enables design flexibility due to a diverse range of mechanical properties, enhancing product durability and aesthetic appeal.

Automotive

Polycarbonate (PC), known for its lightweight and transparent nature, contributes to eye-catching vehicle designs and enhances efficiency by reducing weight without compromising durability or aerodynamics. Its exceptional heat resistance makes it ideal for light housing, headlamp bezels, and lenses. PC blends offer optimal rigidity and excellent creep resistance, making them suitable for both interior and exterior car body parts.

Construction

PC serves as a viable substitute for glass in diverse glazing applications including agricultural structures, industrial and public buildings, facades, security windows, shelters, and skylights. Its attributes of high impact strength, transparency, UV light resistance, and weatherability make it an ideal choice for such purposes.

Consumer goods

Polycarbonate's minimal birefringence, low internal stress, and precise dimensional accuracy make it ideal for CD/DVD manufacturing. Its exceptional transparency enables innovative designs for everyday items like safety goggles, ophthalmic lenses, and large-volume water bottles. Additionally, its optical clarity lends itself to applications such as shatterproof sunglasses, face shields, and bulletproof windows.

Market Outlook:

The automotive sector serves as the primary driver for the global Polycarbonate market, with its utilization in lightweight exterior and interior parts. Polycarbonate's unique properties enable sleek designs while reducing component weight by up to half, particularly in applications like automotive glazing, panoramic roof panels, and backlights. Additionally, its high impact resistance extends its usage to electronic devices, meeting the demand for durable and technologically advanced gadgets. The growing consumer preference for stylish automotive designs and innovative electronics further propels the demand for Polycarbonate, positioning it as a pivotal material in driving industry innovation and meeting evolving market demands. The global Polycarbonate market is anticipated to reach approximately 8.5 million tonnes by 2034.

Polycarbonate Major Manufacturers

Significant companies in the Global Polycarbonate market are Covestro AG, SABIC, Mitsubishi Engineering-Plastics Corporation, Lotte Chemical Corporation, LG Chem, Formosa Chemicals & Fibre Corp., Teijin Limited, Chi Mei Corporation, Idemitsu Kosan Co. Ltd. (Japan), Zhongsha (Tianjin) Petrochemical, SABIC-Sinopc JV, SHELL-CNOOC, LG Dow polycarbonate, Lutianhua Zhonglan New Materials, Wanhua Chemical, and Others.

Polycarbonate market restraints

The Polycarbonate market faces several restraints as well. These are as follows:

Fluctuating Raw Material Prices: Polycarbonate production relies on raw materials like bisphenol A and phosgene, the prices of which are subject to market volatility. Fluctuations in raw material costs can affect the overall production costs and profit margins for Polycarbonate manufacturers.

Environmental Concerns: The production process of Polycarbonate involves the use of chemicals and solvents that can have environmental implications. Stringent environmental regulations aimed at reducing emissions and waste disposal pose challenges for Polycarbonate manufacturers in terms of compliance and operational costs.

Competitive Pressure: The Polycarbonate market faces competition from alternative materials such as acrylics, polyethylene terephthalate (PET), and polystyrene (PS). These materials may offer similar properties at lower costs, posing a threat to Polycarbonate's market share.

Conclusion:

The global Polycarbonate demand, closely tied to Electrical and Electronics, Automotive, and Construction industries, has experienced strong growth in the past few years. Polycarboante’s distinct characteristics, including lightweight nature, high resilience, and resistance to chemicals, suggest an anticipated expansion of the Polycarbonate market in the forecast period. With urbanization activities on the rise, increasing demand for modern electronic devices, and heightened vehicle sales projected, there is expected to be a surge in demand for Polycarbonate by the year2034.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.