Float Glass Market: Technological Advancements Transforming Manufacturing Processes

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Float glass, a fundamental product in the glass industry, has undergone significant transformations due to technological advancements that have revolutionized manufacturing processes. This blog explores how innovations in technology have reshaped the float glass market, enhancing efficiency, product quality, and sustainability across the global glass manufacturing sector.

Understanding Float Glass

Float glass is a type of flat glass produced by floating molten glass on a bed of molten metal, typically tin, which results in a smooth and uniform surface. This method allows for the production of large, thin sheets of glass that are used in various applications such as windows, facades, automotive glass, and solar panels.

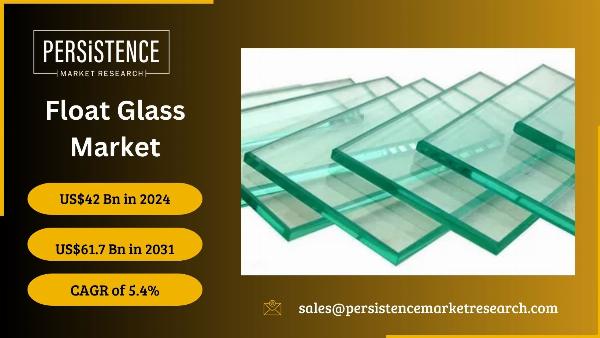

Market Overview and Growth Trends

The global float glass market has experienced steady growth, driven by urbanization, infrastructure development, and the expanding automotive and construction industries PMR’s market research report foresees a CAGR of 5.4% for the float glass market between 2024 and 2031 as it eyes revenue worth US$61.7 Bn in 2031, up from US$42 Bn attained in 2023. Technological advancements play a pivotal role in shaping the market dynamics, offering new opportunities for manufacturers to innovate and improve their production capabilities.

Technological Advancements Transforming Float Glass Manufacturing

• Advanced Float Glass Production Lines: Modern float glass production lines have integrated advanced automation and control systems to enhance efficiency and reduce production costs. These systems monitor and optimize parameters such as glass thickness, quality, and energy consumption in real-time, ensuring consistent product quality.

• Energy-Efficient Melting Technologies: Innovations in glass melting technologies, such as oxy-fuel combustion and electric melting furnaces, have improved energy efficiency and reduced carbon emissions during the glass manufacturing process. This shift towards sustainable practices is driven by regulatory pressures and consumer demand for eco-friendly products.

• High-Performance Coatings and Treatments: The development of high-performance coatings and treatments for float glass has expanded its application scope. Anti-reflective coatings, low-emissivity (low-e) coatings, and self-cleaning treatments enhance the functional properties of glass, making it suitable for energy-efficient buildings and automotive glazing.

• Innovative Glass Compositions: Research and development efforts have focused on developing new glass compositions with enhanced mechanical strength, thermal resistance, and optical clarity. These advancements support the demand for specialty glass products in niche markets such as electronics, healthcare, and aerospace.

• Digitalization and Industry 4.0: Digitalization initiatives and Industry 4.0 technologies, including artificial intelligence (AI), Internet of Things (IoT), and data analytics, are being increasingly adopted in float glass manufacturing. These technologies optimize production processes, predict maintenance needs, and improve supply chain management, driving operational efficiency and productivity.

Benefits and Future Prospects

The integration of technological advancements in float glass manufacturing offers several benefits and future prospects:

• Improved Product Quality: Enhanced precision and control over production parameters result in higher-quality glass products with consistent performance characteristics.

• Cost Efficiency: Automation and energy-efficient technologies reduce operational costs associated with raw materials, energy consumption, and maintenance, improving profitability for manufacturers.

• Environmental Sustainability: Reduced carbon footprint through energy-efficient practices and sustainable manufacturing processes align with global environmental regulations and consumer preferences for eco-friendly products.

• Diversification of Applications: Advanced glass compositions and coatings expand the application possibilities of float glass, catering to evolving market demands in sectors such as architecture, automotive, electronics, and renewable energy.

Conclusion

Technological advancements continue to drive innovation and transformation in the float glass market, revolutionizing manufacturing processes and expanding the application potential of glass products worldwide. As manufacturers embrace digitalization, sustainable practices, and advanced materials science, they are well-positioned to capitalize on emerging opportunities and address challenges in a dynamic global market. The future of float glass lies in leveraging these advancements to deliver high-performance, eco-friendly solutions that meet the evolving needs of industries and consumers alike.

Follow Us: LinkedIn | Medium | Twitter

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.