From Model to Reality: How Revit Prefabrication Drawings Drive Faster Builds

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

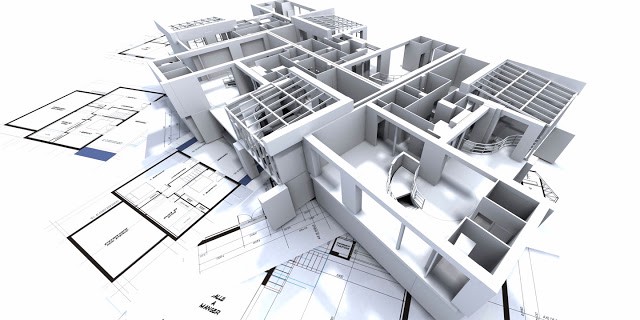

In today’s fast-paced construction world, time, accuracy, and efficiency are everything. Traditional methods often lead to errors, delays, and rework that drain budgets and push deadlines. This is exactly where Revit Prefabrication Drawing Services come into play—bridging the gap between digital models and real-world construction with precision and speed.

At Silicon Valley, we’ve seen firsthand how leveraging Revit for prefabrication not only streamlines the construction process but also helps clients achieve faster, smoother, and more cost-effective builds. Let’s explore how Revit Prefabrication Drawings turn models into reality—and why this approach is transforming the industry.

What Are Revit Prefabrication Drawing Services?

Revit Prefabrication Drawing Services involve generating highly accurate, fabrication-ready drawings directly from Building Information Models (BIM) created in Autodesk Revit. These detailed drawings guide offsite manufacturing of building components, including HVAC systems, MEP modules, structural frames, wall panels, piping, and ductwork.

Unlike traditional 2D drafting, Revit Prefabrication Drawings are derived from intelligent 3D models. These models are rich with data, offering insights on dimensions, materials, quantities, and installation requirements.

Why Prefabrication Matters More Than Ever

Prefabrication is not a trend—it’s the future of construction. Offsite fabrication reduces on-site congestion, lowers labor costs, minimizes waste, and speeds up the assembly process. However, prefabrication only works efficiently when it’s backed by precise and detailed drawings. That’s where Revit Prefabrication Drawing Services become essential.

How Revit Prefabrication Drawings Drive Faster Builds

1. Accurate, Data-Driven Models for Fabrication

Revit models are more than just 3D visuals—they contain all the necessary data to guide manufacturing. From precise dimensions to material specifications, the prefabrication drawings generated from Revit ensure every component is produced exactly as needed. This accuracy eliminates guesswork, reduces fabrication errors, and speeds up the production process.

2. Seamless Clash Detection Before Fabrication

Clash detection is a key advantage of Revit BIM. Before any part is manufactured, the system identifies spatial conflicts between elements—such as HVAC ducts intersecting with structural beams or plumbing lines. This proactive error detection means that problems are solved in the digital environment, not on the job site—saving time, money, and labor.

3. Faster Turnaround from Model to Manufacturing

Traditional drafting requires manual generation of multiple views and sections. With Revit, prefabrication drawings are automatically extracted from the model with high accuracy. This significantly reduces the turnaround time from the design phase to the manufacturing stage, enabling contractors to start fabrication sooner.

4. Standardization for Speed

Revit supports the use of standardized parts, assemblies, and families. This means repetitive elements like duct runs, piping, or wall panels are modeled once and reused across the project. Prefabrication drawings generated from these standardized models ensure consistency, speed up manufacturing, and reduce errors.

5. Real-Time Updates and Change Management

Any changes made in the Revit model are instantly reflected in the prefabrication drawings. This dynamic link between the model and documentation ensures that manufacturers always have the latest information, avoiding costly errors caused by outdated drawings.

6. Reduced On-Site Labor and Installation Time

With precisely fabricated components delivered to the site, installation becomes faster and more predictable. Fewer field adjustments are needed because everything is designed to fit perfectly. This reduction in on-site labor accelerates project timelines considerably.

7. Improved Collaboration Across Teams

Revit enables cloud-based collaboration, allowing architects, engineers, contractors, and fabricators to work together in real-time. This shared environment minimizes communication gaps, ensures alignment, and speeds up decision-making—all of which contribute to faster builds.

Real-World Applications of Revit Prefabrication Drawings

- MEP Systems: Accurate shop drawings for ductwork, piping, plumbing, and electrical trays, ready for prefabrication.

-

Structural Components: Fabrication drawings for steel frames, precast concrete panels, beams, and columns.

-

Modular Construction: Prefabricated modules for bathrooms, kitchens, and medical units, delivered with precision.

-

HVAC Systems: Detailed duct fabrication drawings with hanger layouts, insulation details, and joint specifications.

Key Benefits for Stakeholders

- Contractors: Faster installation, less downtime, fewer site errors.

- Fabricators: Accurate drawings reduce waste, improve efficiency, and streamline production.

- Owners: Projects are delivered faster with better quality and reduced costs.

- Design Teams: Changes are easier to manage, and coordination improves across disciplines.

Why Choose Silicon Valley for Revit Prefabrication Drawing Services?

At Silicon Valley, we combine 20+ years of experience in BIM solutions with a commitment to quality, precision, and client satisfaction. Our Revit Prefabrication Drawing Services help clients worldwide achieve smooth fabrication and faster project delivery.

Our offerings include:

- BIM Fabrication Services for accurate, build-ready models.

- BIM Prefabrication Outsourcing Services for cost-effective, remote support.

- Revit MEP Prefabrication Drawing Services for HVAC, plumbing, and electrical systems.

- Structural and Architectural Prefabrication Drawings for modular builds, precast, and steel fabrication.

Additionally, we support digital transformation with NodeJS Development Services, Full Stack Development Services, and PHP Development Services, helping clients accelerate their growth in both the construction and digital landscapes.

Conclusion

The future of construction is faster, smarter, and more precise—and Revit Prefabrication Drawing Services are a key driver of that future. By bridging the gap between virtual models and physical reality, these services enable quicker fabrication, smoother installations, and better project outcomes.

Partner with Silicon Valley to turn your models into reality—and watch your projects move from concept to completion at record speed.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.