FTI Incorporation Introduces Advanced Visual Inspection Set in France, Enhances Vial Defect Detection and Upholds Global Visual Inspection Standards

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

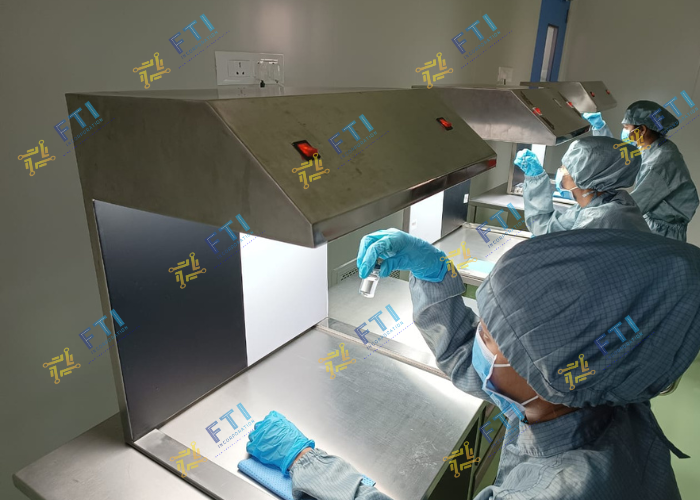

FTI Incorporation, a leader in forensic technological innovations, is proud to announce the launch of its Visual Inspection Set in France, designed to meet the stringent requirements of various industries, particularly pharmaceuticals and medical devices. Alongside this, FTI is also bringing its expertise in vial defect detection in France and continues to adhere to the highest visual inspection standards to ensure product safety and quality.

Visual Inspection Set in France: A New Standard for Quality Assurance

Visual inspection is a key process in industries such as pharmaceuticals, medical devices, and manufacturing, where product safety and quality are critical. FTI Incorporation’s Visual Inspection Set in France is engineered to help companies ensure that their products meet the highest safety and quality standards by detecting any visible defects or particle contamination.

What is a Visual Inspection Set?

A Visual Inspection Set includes the tools and equipment required to conduct manual or automated inspections of products to check for visible defects such as cracks, particles, discoloration, or structural flaws. The key features of FTI’s Visual Inspection Set include:

- High-Intensity Lighting: To make sure even the smallest particles and defects are visible, the inspection area is illuminated with lighting that ranges between 2000 and 3750 lux, following international guidelines.

- Magnification Tools: To assist inspectors in identifying defects that are not visible to the naked eye, the set comes with high-quality magnifying glasses and microscopes.

- Turntable for Rotation: The inspection set includes a turntable that rotates the product, ensuring that all sides are examined thoroughly during the inspection process.

- Vision Systems: FTI’s Visual Inspection Set in France also includes advanced automated vision systems with cameras and software, which automatically detect any defects, helping companies speed up the inspection process and increase accuracy.

The Visual Inspection Set in France is suitable for pharmaceutical companies, medical device manufacturers, and any other industries where visual inspection is a crucial part of quality assurance.

Vial Defect Detection in France: Ensuring the Safety of Sterile Products

FTI Incorporation has a deep understanding of the pharmaceutical industry's need for precise defect detection, especially when it comes to vials, which are commonly used to package sterile products like injectable medicines. FTI’s Vial Defect Detection in France ensures that pharmaceutical companies can detect defects in vials before they reach consumers, thus safeguarding patient safety and complying with regulatory requirements.

What Are the Common Defects in Vials?

Vials can develop a range of defects during the manufacturing process, including:

1. Cracks: Even small cracks in a vial can lead to contamination or leakage, making the product unsafe for use.

2. Particles: Foreign particles inside vials can pose serious health risks to patients, especially when the product is meant for injection.

3. Discoloration: Any change in the color of the vial or its contents can indicate contamination or chemical reactions, rendering the product unsafe.

4. Seal Defects: Improper seals can compromise the sterility of the vial’s contents, leading to potential health hazards.

Through advanced visual inspection and automated systems, FTI’s Vial Defect Detection in France helps pharmaceutical companies identify these defects early in the production process, ensuring that only high-quality, defect-free products reach the market.

Adhering to Global Visual Inspection Standards

At FTI Incorporation, we understand that maintaining compliance with global visual inspection standards is crucial for any company that wants to operate in highly regulated industries like pharmaceuticals, medical devices, and food production. We follow and implement international visual inspection standards to help our clients stay compliant with regulatory bodies such as the FDA and European Medicines Agency.

What Are Visual Inspection Standards?

Visual inspection standards are a set of guidelines and procedures that dictate how inspections should be carried out, ensuring consistency, safety, and quality in the products being inspected. The standards cover aspects like:

- Lighting Intensity: Standards require lighting in the range of 2000 to 3750 lux during visual inspection to ensure visibility of small particles and defects.

- Inspector Training: Only trained professionals are allowed to perform manual inspections to maintain a high level of accuracy.

- Inspection Environment: The environment must be clean and controlled to prevent external contaminants from affecting the results.

FTI Incorporation’s visual inspection processes are aligned with these global standards, ensuring that our clients’ products meet the highest levels of safety and quality.

Benefits of FTI Incorporation’s Visual Inspection Solutions

By choosing FTI Incorporation’s Visual Inspection Set in France and Vial Defect Detection in France, companies can benefit in multiple ways:

1. Improved Product Quality: Visual inspection helps in identifying and removing defective products before they reach the market, thus maintaining a company’s reputation for quality.

2. Regulatory Compliance: Adhering to global visual inspection standards ensures that products meet the necessary regulatory requirements for safety and quality.

3. Cost Savings: Early detection of defects can help companies avoid costly product recalls and legal liabilities.

4. Enhanced Safety: Visual inspection is essential in industries where product contamination or defects can have severe health consequences, such as in pharmaceuticals and medical devices.

FTI Incorporation: A Global Leader in Visual Inspection Technology

FTI Incorporation is a trusted name in visual inspection technology and has expanded its services to meet the growing demands of global markets. Our Visual Inspection Set in France and Vial Defect Detection in France are the latest additions to our portfolio, designed to offer cutting-edge solutions for industries that require precise and reliable quality control.

FTI Incorporation has offices in India and the USA, providing global support to clients across multiple sectors. Whether you are looking for visual inspection solutions in pharmaceuticals, medical devices, or manufacturing, FTI is here to help you meet your quality assurance needs.

Contact Details

For more information about our Visual Inspection Set in France, Vial Defect Detection in France, or our adherence to visual inspection standards, please contact us:

Phone: +91 8200487148 | +91 9638344845

Email: [email protected] | [email protected]

Indian Address:

Forensic Technological Innovation, Incubated at National Forensic Sciences University,

Sector 9, Gandhinagar, Gujarat 382007, India.

USA Office:

58 Albert Ct, City: Randolph,

State: New Jersey, Zip Code: 07869, USA.

FTI Incorporation continues to lead the way in forensic technology and visual inspection solutions, helping businesses worldwide ensure their products are safe, compliant, and of the highest quality.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.