Global Insulation Coating Market Trends, Growth, and Demand Analysis

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

The global insulation coating market is experiencing rapid growth, driven by increasing demand for energy efficiency, corrosion protection, and sustainability across various industries. Insulation coatings play a crucial role in reducing heat loss, improving safety, and extending the lifespan of equipment and infrastructure. These coatings are widely used in automotive, aerospace, industrial, oil & gas, construction, and marine applications, making them an essential part of modern industrial operations.

Get the full access on Global Insulation Coating Market Research Report by Ken Research!

With advancements in nanotechnology, eco-friendly formulations, and high-performance coatings, the market is set to witness significant expansion. The growing adoption of insulation coatings for fire protection, thermal management, and corrosion resistance is further fueling demand.

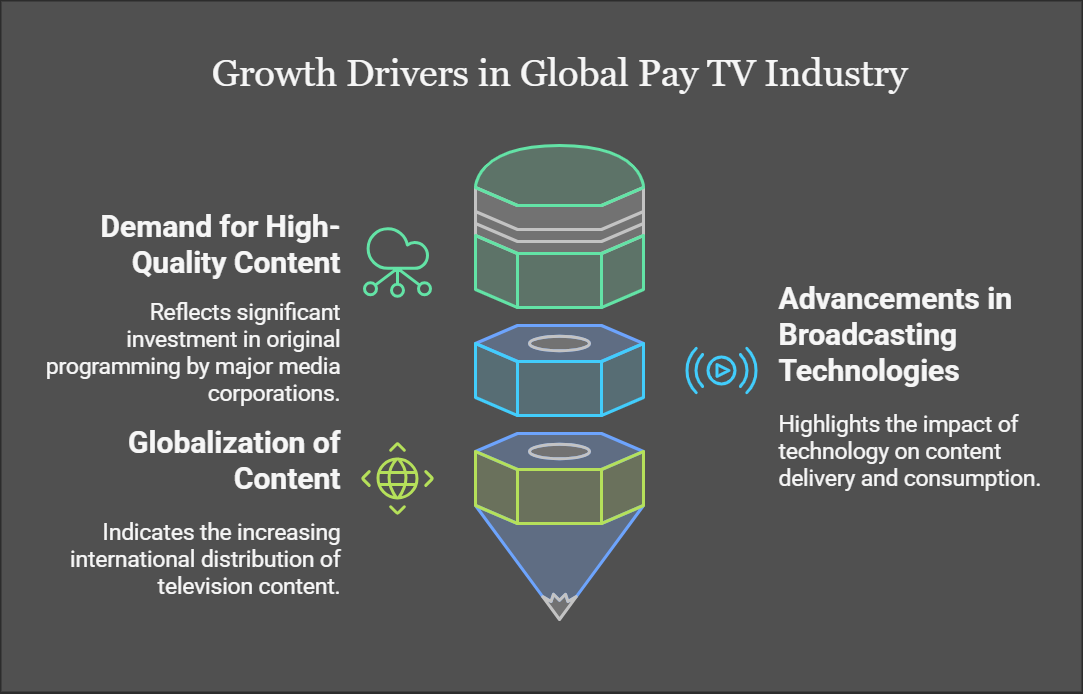

Market Trends in the Global Insulation Coating Industry

1. Rising Focus on Energy Efficiency and Sustainability

Governments and industries worldwide are emphasizing energy efficiency to reduce carbon emissions and operational costs.

Eco-friendly insulation coatings, made from low-VOC and bio-based materials, are gaining traction in compliance with global environmental regulations.

The shift towards green buildings and energy-saving infrastructure is increasing the use of high-performance insulation coatings in construction.

2. Increasing Adoption in the Automotive and Aerospace Sectors

Lightweight and high-heat-resistant coatings are being integrated into electric vehicles (EVs) and fuel-efficient aircraft.

Automakers and aircraft manufacturers are using insulation coatings to improve fuel efficiency and protect components from extreme temperatures.

The rapid expansion of the EV industry is driving demand for thermal barrier coatings that enhance battery performance and safety.

3. Growth in Oil & Gas and Industrial Applications

High-temperature insulation coatings are widely used in refineries, petrochemical plants, and offshore platforms to prevent heat loss and corrosion.

Heat-resistant ceramic coatings are improving pipeline efficiency and extending the lifespan of industrial equipment.

The industrial sector's focus on corrosion resistance and fireproofing is increasing the demand for specialized insulation coatings.

4. Technological Advancements in Nano-Insulation Coatings

Nanotechnology-based coatings offer superior thermal resistance, lightweight properties, and enhanced durability.

These coatings are finding applications in electronics, medical devices, and space exploration.

Graphene-based insulation coatings are emerging as a next-generation solution, offering exceptional heat dissipation and electrical insulation.

5. Increasing Demand for Fireproof and Anti-Corrosion Coatings

Fire-resistant insulation coatings are becoming standard in construction, automotive, and marine applications.

Corrosion-resistant coatings are in high demand for bridges, railways, and marine vessels, ensuring long-term infrastructure durability.

Industries are investing in advanced ceramic and polymer-based coatings to protect equipment from moisture, chemicals, and extreme weather conditions.

Market Growth Drivers

1. Expanding Construction Industry and Smart Cities Development

The rise of smart cities and energy-efficient buildings is driving demand for insulation coatings in facades, roofing, and HVAC systems.

Governments are enforcing strict energy codes that promote the use of thermal insulation coatings in construction materials.

Reflective and cool-roof coatings are gaining popularity in hot climate regions, reducing energy consumption for cooling.

2. Increasing Investments in Renewable Energy Projects

Wind and solar energy industries are incorporating insulation coatings to enhance efficiency and protect components from harsh environmental conditions.

Heat-resistant and UV-resistant coatings improve the longevity of solar panels and wind turbine blades.

The shift toward carbon neutrality and green energy solutions is accelerating market expansion.

3. Growth in Industrial and Manufacturing Sectors

The rise in industrial automation and smart manufacturing is fueling demand for protective coatings in machinery and processing plants.

Anti-condensation coatings are being used in food processing, pharmaceutical, and chemical industries to maintain temperature stability and prevent corrosion.

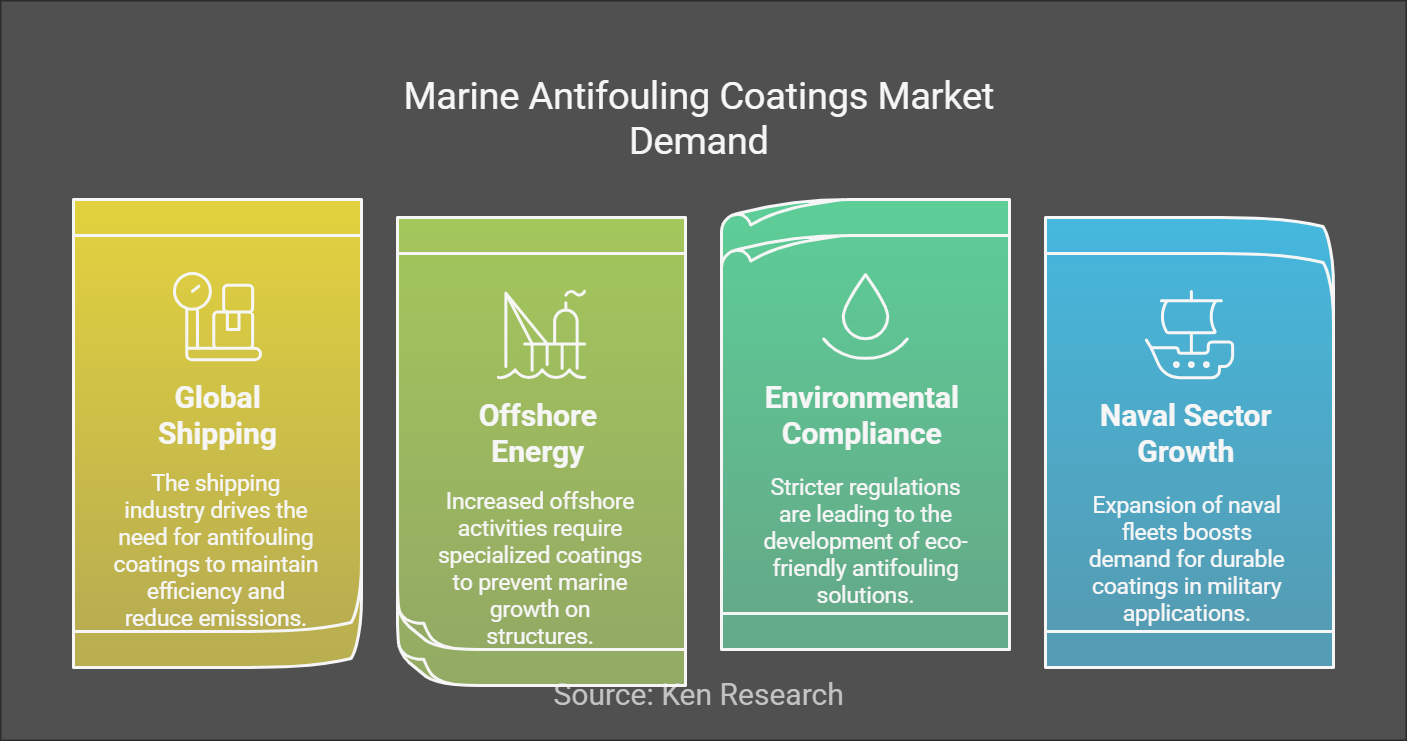

4. Rising Demand for High-Performance Insulation in Defense and Marine Applications

The defense sector is utilizing thermal barrier coatings in military vehicles, ships, and aircraft for protection against extreme environments.

Marine insulation coatings are crucial for shipbuilding and offshore platforms, preventing heat loss and corrosion in high-salinity conditions.

Demand Analysis in the Global Insulation Coating Market

1. Regional Market Insights

North America: Leading the market due to strict energy efficiency regulations, high R&D investments, and demand from the aerospace and automotive industries.

Europe: Growth driven by EU sustainability policies, rising adoption of electric vehicles, and expansion in the renewable energy sector.

Asia-Pacific: Fastest-growing market due to rapid industrialization, booming construction sector, and increasing infrastructure projects in China, India, and Japan.

Middle East & Africa: Rising investments in oil & gas, commercial buildings, and transportation infrastructure are boosting market demand.

2. Industry Segmentation

By Material Type: Ceramic, Epoxy, Acrylic, Polyurethane, and Nanotechnology-based coatings.

By End-Use Industry: Construction, Automotive, Aerospace, Oil & Gas, Industrial, Marine, and Energy.

By Application: Thermal insulation, Anti-corrosion, Fireproofing, Electrical insulation, and Soundproofing.

Future Outlook for the Insulation Coating Market

By 2028, the global insulation coating market is expected to witness:

Higher adoption of nano-insulation coatings for high-performance applications in electronics, space, and defense sectors.

Expansion in the use of smart coatings, integrating self-healing, self-cleaning, and temperature-adaptive functionalities.

Advancements in eco-friendly and bio-based insulation coatings to comply with global sustainability goals.

Growth in customized solutions for extreme environments, including cryogenic storage and high-altitude aerospace applications.

Increased investment in R&D by key players to develop ultra-thin, lightweight, and high-durability coatings.

Conclusion

The global insulation coating market is on a growth trajectory, fueled by technological advancements, increasing energy efficiency mandates, and the rise of eco-friendly solutions. As industries prioritize thermal management, corrosion resistance, and fireproofing, the demand for high-performance insulation coatings will continue to rise.

Companies that innovate in sustainable, nano-based, and multifunctional coatings will dominate the market in the coming years. With strong investments in industrial applications, renewable energy, and smart infrastructure, the future of insulation coatings looks promising for both manufacturers and end-users worldwide.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.