DA 70+ Guest Post Placements – Elite Authority at Your Fingertips!

DA 70+ Guest Post Placements – Elite Authority at Your Fingertips!

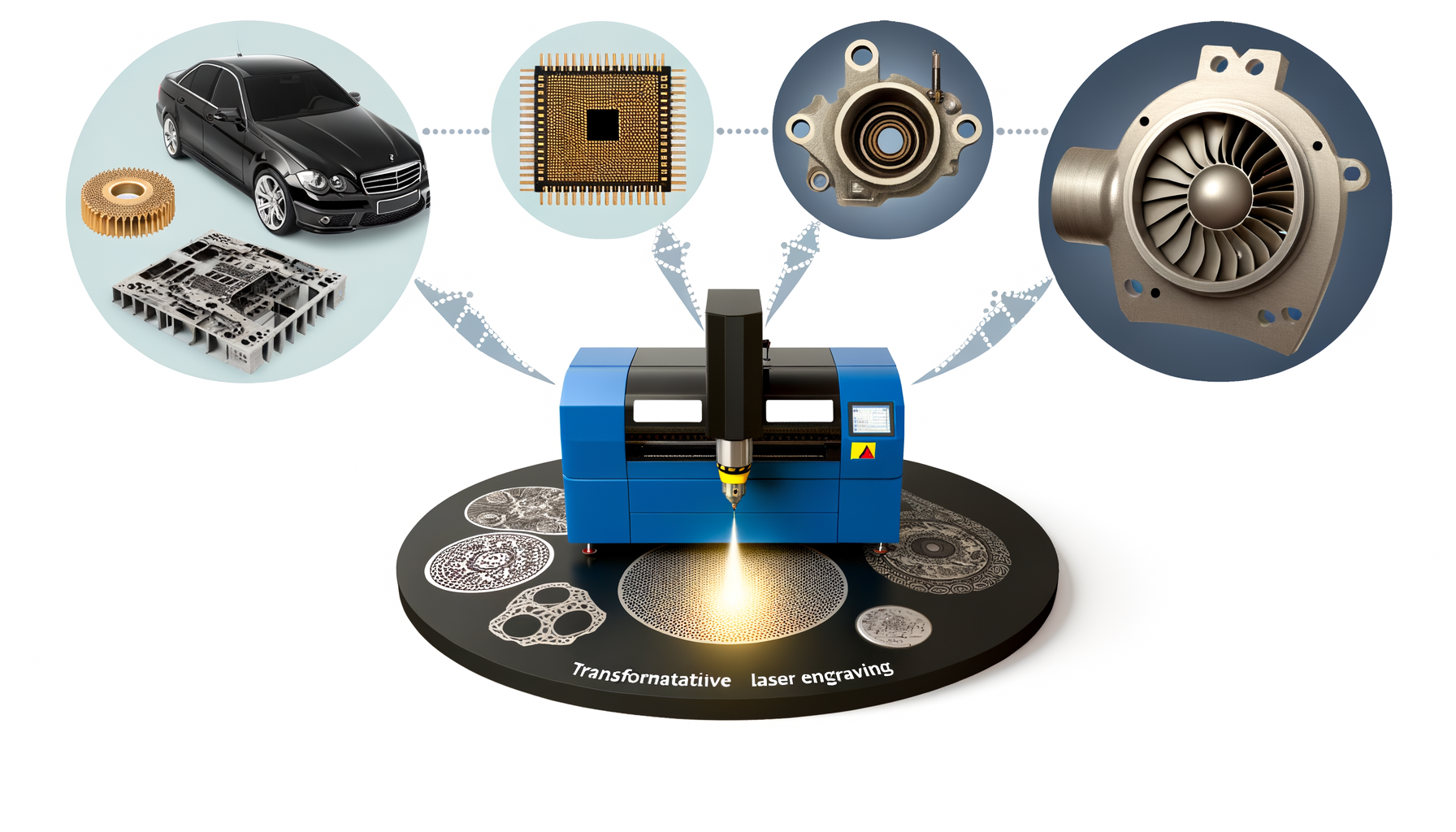

Harnessing Laser Engraving: Industry Transformations in Aerospace, Automotive, and Electronics

Written by Shraddha Shinde » Updated on: June 17th, 2025

Laser engraving machines have been pivotal in enhancing manufacturing precision and efficiency across various industries. The aerospace, automotive, and electronics sectors are leading the charge in innovation and application, driving substantial market growth. This article delves into the expanding applications of laser engraving machines in these sectors, illustrating how they are shaping the future of technology and industry service. We'll explore the transformative impact these machines are having by enhancing product reliability, reducing production times, and fostering sustainable practices.

Aerospace: Reaching New Heights

The aerospace sector is both a pioneer and beneficiary of laser engraving technology. Given the industry's demanding standards for precision and durability, laser engraving boasts distinct advantages:

1. Component Identification:

Laser engraving is used extensively for marking pivotal information on components such as serial numbers and part identifications. This precision is crucial in ensuring the traceability and authenticity of parts.

2. Surface Texturing:

Engraving allows for detailed surface texturing that enhances the aerodynamic efficiency of aircraft parts. This has been known to improve fuel efficiency and reduce emissions.

3. Durability and Weight Reduction:

Unlike traditional methods that might compromise material integrity, laser engraving maintains the unchanged mass balance of components while offering long-lasting markings resistant to extreme temperatures and friction.

Enhancing Safety and Compliance

Engraving essential data on parts ensures safety protocols are met and facilitates regulatory compliance. This plays a vital role in averting malfunctions and elongating the lifecycle of the aircraft.

Automotive: Driving Innovation Forward

The automotive industry continues to integrate laser technology for its capability to provide faster, more reliable, and cost-efficient solutions:

1. Part Identification and Serialization:

Laser engraving enables the serial marking of thousands of parts in a rapid, efficient manner. This process is crucial for inventory management and counteracting counterfeit issues.

2. Enhanced Aesthetic Design:

From dashboard elements to exterior decorations, laser engraving provides unparalleled customization options for vehicle manufacturers.

3. Customization and Branding:

Brands like Tesla and BMW are adopting laser engraving to personalize vehicles with model-specific engravings, fostering brand loyalty and exclusivity.

Boosting Production Line Efficiency

The automation capability of laser engraving machines reduces turnaround time and workforce demand, thereby cutting production costs and enhancing overall workflow processes.

Electronics: Precision in Micro-Machining

The ever-evolving electronics sector relies heavily on laser engraving for micro-machining, which is crucial in maintaining the miniaturization of devices without sacrificing detail or quality:

1. Micro-Engraving:

Laser technology is pivotal in marking intricate circuit boards and chips, which conventionally would be impossible with other techniques.

2. Data Matrix and QR Codes:

Laser engraving can efficiently engrave tiny QR codes and data matrix codes vital for traceability and quality control.

3. Produce Mass Miniaturization:

Ensuring precision on a miniature scale is essential for component integrity and functionality in electronics, an area where laser engraving excels.

Efficiency and Reliability

The non-contact nature of laser processes ensures that fragile components are marked without damage, significantly reducing the risk of product malfunction and increasing lifespan.

The Future Outlook: Sustainable Growth and Beyond

The emerging trends and burgeoning applications in laser technology herald a promising horizon. As industries globally work towards sustainability, the eco-friendly nature of laser engraving will become an even greater benefit. Traditional marking methods, often waste-heavy and chemical-dependent, face displacement by laser engraving solutions that offer:

1. Reduced Waste and Energy Usage:

Laser technology eliminates the need for consumable marking materials and operates with lower power consumption, aligning with eco-conscious movements.

2. Extended Lifespan and Reduced Costs:

Markings are resilient, reducing litter from replacements and enhancing product lifespan—a direct boon to cost efficiency and sustainability.

Conclusion: A Unified Technological Force

Industries are increasingly recognizing the unparalleled advantages offered by laser engraving machines. With their expanding applications, these machines stand ready to redefine manufacturing paradigms across the aerospace, automotive, and electronics sectors. As technological advancements continue, the potential for expanded uses grows setting the stage for continued innovation and market growth beyond today's benchmarks. By embracing this transformative technology, these industries are paving the way for a future where excellence and sustainability are not merely goals, but standards.

Explore Comprehensive Market Analysis of Laser Engraving Machines Market

SOURCE -- @360iResearch

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.