High-Quality Injection Molding Services by Precious3D

Understanding Delrin, Polycarbonate, and Nylon Injection Molding – Precious3D

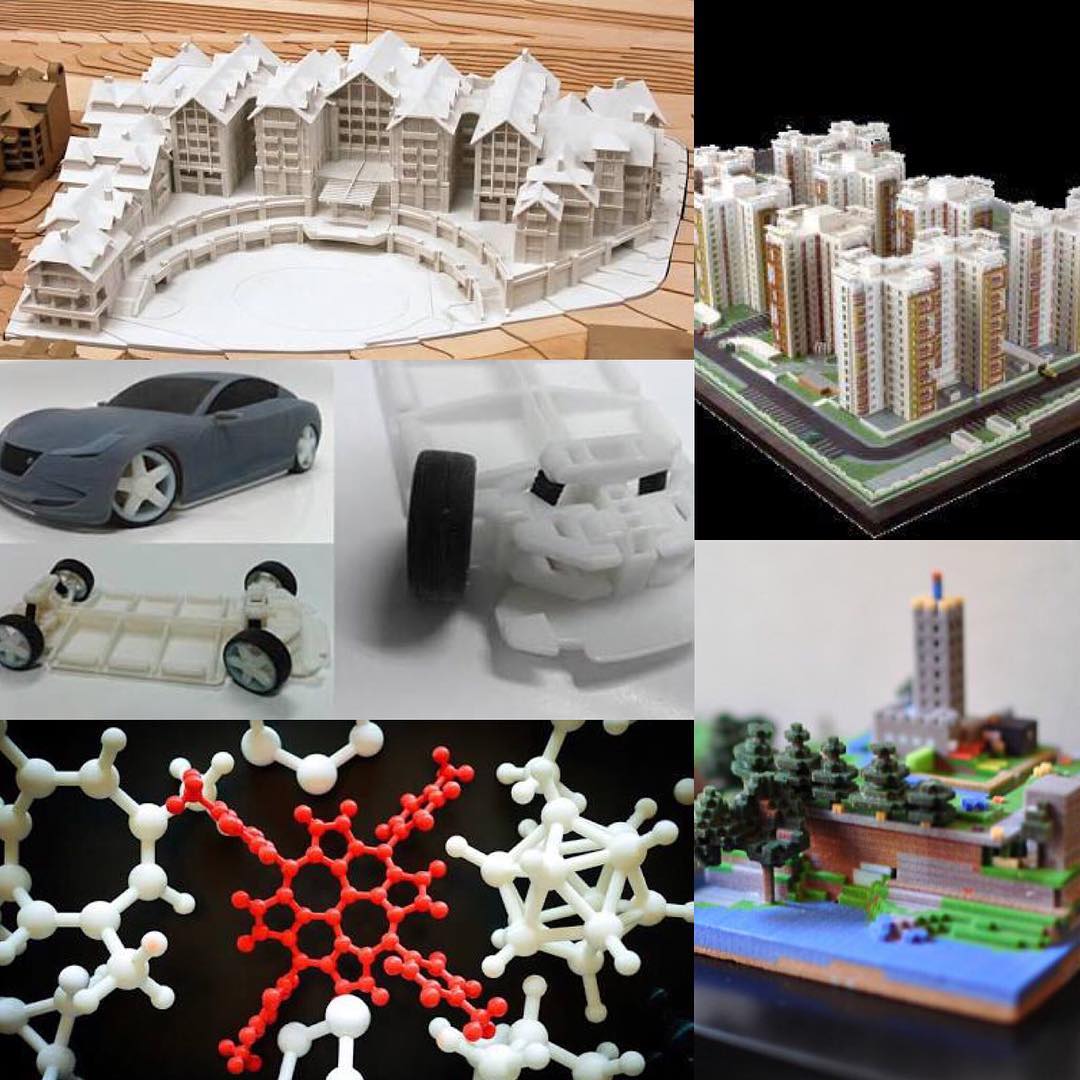

Injection molding is a widely used manufacturing process for producing plastic components with high precision and efficiency. Among the many materials available, Delrin injection molding, polycarbonate injection molding, and nylon injection molding are three common techniques that offer distinct advantages depending on the application. At Precious3D, we specialize in delivering high-quality molded parts tailored to meet industry-specific needs.

Delrin Injection Molding

Delrin injection molding utilizes Delrin, a high-performance acetal resin known for its excellent mechanical properties, durability, and low friction. Delrin is widely used in precision engineering applications due to its:

High stiffness and strength – Ensures reliable structural integrity.

Low friction and wear resistance – Ideal for moving parts such as gears and bearings.

Chemical and moisture resistance – Suitable for harsh environments, including automotive and industrial applications.

At Precious3D, we ensure optimal processing conditions for Delrin, preventing defects such as warping and shrinkage, which are common in acetal-based materials. With Delrin injection molding, we provide components for industries like medical devices, consumer electronics, and automotive manufacturing.

Polycarbonate Injection Molding

Polycarbonate injection molding is another widely used process that offers exceptional clarity, impact resistance, and heat resistance. Polycarbonate is preferred for applications requiring transparency, such as:

Optical components – Lenses, safety glasses, and LED covers.

Automotive parts – Headlight covers and dashboards.

Electronic housings – Protective casings for electrical devices.

At Precious3D, we use polycarbonate injection molding to create strong and durable parts with precise dimensions. Our expertise in processing polycarbonate ensures resistance to cracking and high-temperature distortion. We also offer customized polycarbonate formulations, including flame-retardant and UV-resistant variants, depending on the application.

Nylon Injection Molding

Nylon injection molding is widely used in industrial, automotive, and consumer applications due to nylon’s exceptional strength, toughness, and resistance to abrasion. Key benefits of nylon injection molding include:

High mechanical strength – Excellent durability for structural applications.

Wear and chemical resistance – Suitable for automotive and industrial parts.

Lightweight yet strong – Ideal for reducing material weight in engineering applications.

At Precious3D, we leverage nylon injection molding for producing components such as gears, bushings, and fasteners. Our advanced molding techniques ensure superior performance, dimensional stability, and long service life.

Why Choose Precious3D?

At Precious3D, we take pride in offering Delrin injection molding, polycarbonate injection molding, and nylon injection molding solutions with unmatched quality and precision. Here’s why our customers trust us:

Advanced Manufacturing Technology – We utilize cutting-edge injection molding machines with high accuracy and repeatability to ensure consistent quality.

Material Expertise – Our team understands the unique properties of Delrin, polycarbonate, and nylon, optimizing the molding process to prevent defects and enhance durability.

Custom Design & Engineering Support – We work closely with clients to develop tailored molding solutions, assisting in material selection, mold design, and production strategies.

Scalability & Efficiency – Whether you need small batch production or large-scale manufacturing, we ensure cost-effective and timely delivery without compromising quality.

Strict Quality Control – Our rigorous quality assurance processes, including dimensional inspections and performance testing, guarantee defect-free components.

Industry-Specific Applications – We cater to automotive, medical, consumer electronics, industrial, and aerospace sectors, ensuring that every product meets industry regulations and standards.

Eco-Friendly Practices – We prioritize sustainable manufacturing by optimizing material usage, reducing waste, and offering recyclable plastic options.

Whether you need custom-molded components or mass production of plastic parts, Precious3D guarantees the highest standards of quality and reliability. Contact us today for tailored solutions in Delrin, polycarbonate, and nylon injection molding.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.