How Does a Drop Impact Tester Help Prevent Product Damage in Transit?

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In today’s fast-paced e-commerce and manufacturing landscape, ensuring your product reaches the customer intact is just as important as the product itself. Every day, thousands of packages are shipped, stacked, and handled under various conditions. Even the most carefully designed packaging may fail if it hasn’t been rigorously tested. That’s where a drop tester—specifically a drop impact tester—comes into play.

This blog explores how drop testers work, why drop tests are critical, the importance of drop test standards, and how investing in the right equipment can significantly improve your product’s durability and customer satisfaction.

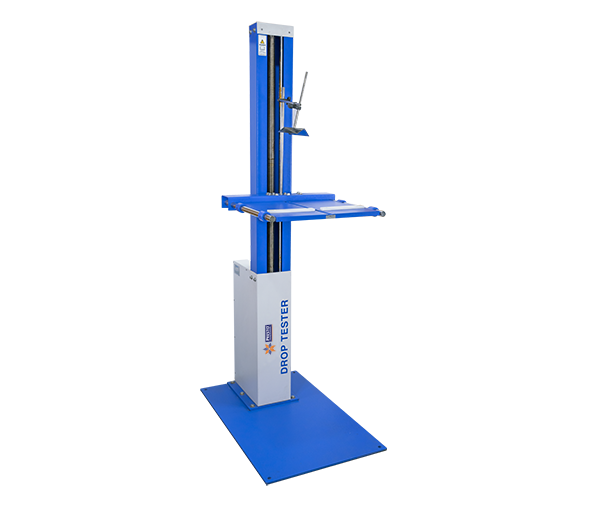

What is a Drop Tester?

A drop tester is a laboratory testing instrument used to simulate the real-world impact of packages being dropped during handling, shipping, and storage. It is primarily used to evaluate the structural integrity of packaging and its ability to protect the contents inside.

The device allows operators to drop a package from specified heights and angles (flat, edge, or corner) onto a hard surface to assess how well the packaging withstands the force of impact. This test helps detect potential weak points in packaging design before a product is mass-shipped.

Why is Drop Testing Important?

Drop tests are more than just routine checks—they are essential for ensuring product safety and durability. Here’s why:

- Minimizes Shipping Damage: By simulating worst-case handling scenarios, you can improve packaging design to prevent damage during transit.

- Reduces Return Rates: Products that arrive broken lead to higher returns, negative reviews, and lost customer trust.

- Ensures Compliance: Drop testing helps you meet various industry regulations and drop test standards like ASTM D5276 and ISTA 1A/2A.

- Optimizes Packaging Materials: Avoid over-packaging or under-packaging by finding the ideal material balance.

Drop Test Standards You Should Follow

To ensure consistent, measurable results, several recognized drop test standards have been established. These include:

- ASTM D5276: Standard method for free-fall drop testing of packaged goods.

- ISTA 1A/2A: Defines procedures for drop testing small to medium-sized packages under controlled lab conditions.

- ISO 2248: Specifies vertical impact testing by free fall.

These standards help manufacturers and labs conduct repeatable, internationally accepted tests, making results more credible and actionable.

How Does a Drop Impact Tester Work?

A drop impact tester typically consists of:

- A motorized or manual lifting mechanism to elevate the test sample.

- A drop arm or platform that releases the sample in a free-fall motion.

- A rigid base surface that receives the impact.

- Controls to adjust drop height and orientation (flat, edge, or corner).

- Once the drop is executed, visual inspection or instrumented analysis is done to assess any deformation, cracks, or internal damage.

Some advanced models come with digital height adjustment, programmable test cycles, and compliance with multiple test standards.

Industries That Benefit from Drop Testing

A drop tester is a versatile tool used in several industries:

- Packaging & Logistics: For evaluating cartons, corrugated boxes, and foam inserts.

- Electronics: Ensures mobile phones, laptops, and other gadgets can survive accidental drops.

- Pharmaceuticals: Protects fragile items like vials, bottles, and medical kits.

- E-commerce: Ensures customer parcels arrive without damage during shipping.

- Automotive: For testing lightweight parts, plastic components, and storage containers.

Drop Tester Price Considerations

The price of a drop tester depends on several factors:

- Drop height range

- Load-bearing capacity

- Manual or motorized operation

- Build quality and material

- Compliance with international standards

- Data logging or display features

Reliable models from trusted manufacturers like Presto balance performance with value, offering long-lasting build quality and after-sales service support.

Final Thoughts

A drop tester is more than just an instrument—it’s a safety net for your product’s reputation. Conducting proper drop tests using standardized methods helps reduce shipping losses, customer complaints, and product damage. Investing in a drop impact tester ensures that your packaging can withstand the demands of the real world.

Whether you are a packaging engineer, quality control specialist, or manufacturer, using a drop tester is a smart step toward delivering safer, more reliable products to your customers.

Looking to protect your products from transit damage?

📞 Call: +91 9210 903 903

📧 Email: [email protected]

Drop Test with Confidence – Choose Presto Drop Testers Today!

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.