How Precast Detailing Services Are Transforming the AEC Industry with Precision & Efficiency

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Introduction

The Architecture, Engineering, and Construction (AEC) industry is constantly evolving, with new methods and technologies reshaping the way projects are planned and executed. One of the most significant advancements in recent years is Precast Detailing Services, which have brought an unprecedented level of accuracy, efficiency, and reliability to the field.

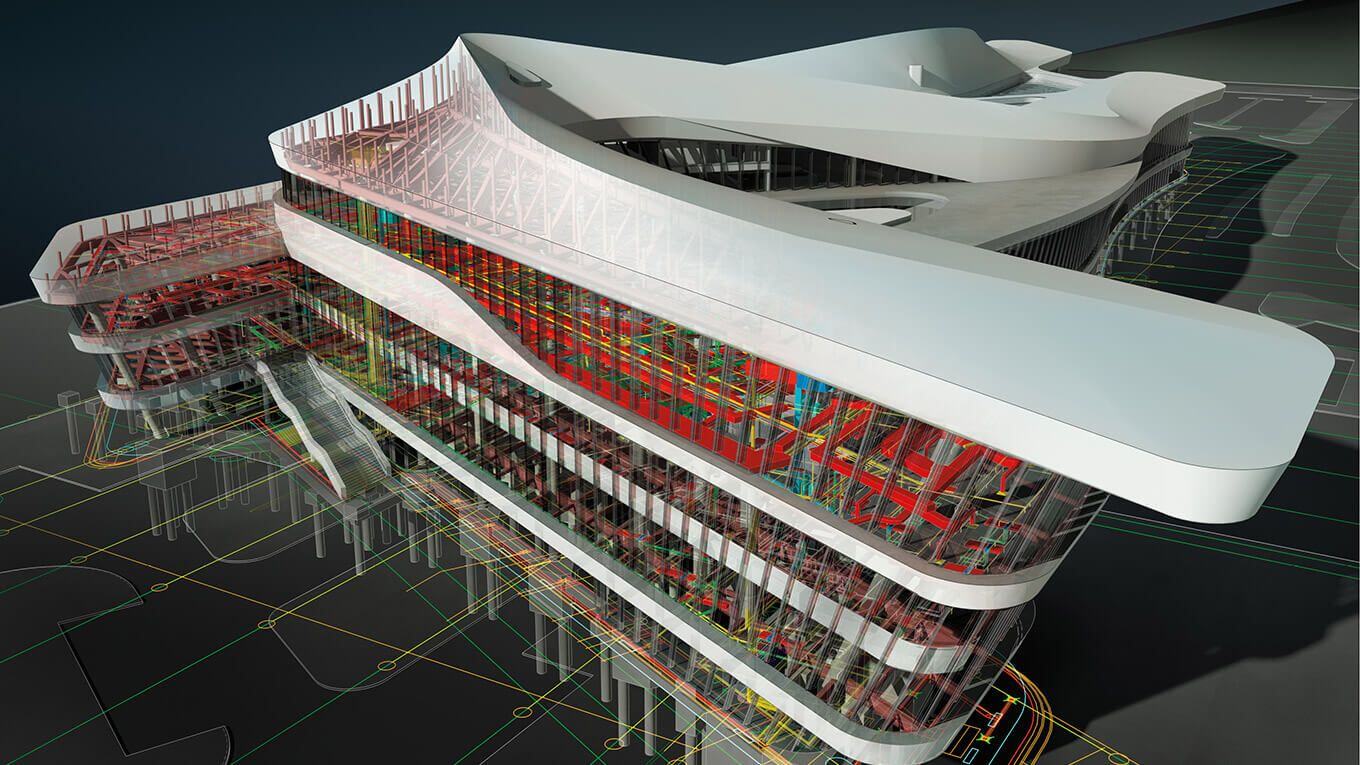

This specialized approach involves creating highly detailed drawings and 3D models for precast concrete components, ensuring that every element is precisely designed before manufacturing. With the shift toward digital workflows and automation, precast detailing has become a game-changer, allowing professionals to streamline operations, minimize errors, and improve overall project outcomes.

In this blog, we’ll explore how precast detailing services are influencing the AEC sector, why they are gaining widespread adoption, and what the future holds for this essential service.

The Role of Precast Detailing in Modern Design & Engineering

Precast detailing plays a crucial role in developing customized, prefabricated concrete elements used in various applications. These components, such as slabs, walls, beams, and columns, are designed and modeled with high precision before they are manufactured. This detailed planning helps eliminate uncertainties, making assembly and installation more efficient.

Unlike traditional approaches, where elements are shaped and formed on-site, precast components are pre-engineered and manufactured in a controlled setting. This ensures a higher level of consistency, reducing human errors and material wastage.

With Precast Detailing Services, professionals can visualize an entire project before production begins. Advanced software tools, including Building Information Modeling (BIM) and CAD, facilitate precise planning and seamless integration of each component, reducing delays and optimizing overall performance.

Why AEC Firms Are Turning to Precast Detailing

The demand for Precast Detailing Services has increased due to their numerous benefits. Here’s why they are becoming a preferred choice for professionals across the AEC sector:

1. Accelerating Project Timelines

One of the primary advantages of precast detailing is the time-saving aspect. Traditional approaches often require extensive on-site labor, which can lead to delays due to weather conditions, workforce availability, or last-minute changes.

With precast detailing, each concrete element is designed in advance, manufactured under controlled conditions, and then delivered for assembly. This streamlined workflow eliminates unexpected disruptions and ensures that the process runs efficiently.

2. Improving Quality & Durability

When elements are created in an uncontrolled setting, inconsistencies can occur, leading to structural weaknesses or defects. Precast detailing services eliminate these risks by enabling precise engineering, ensuring that each component meets industry standards and project specifications.

Moreover, precast elements undergo rigorous quality control measures before reaching the site, ensuring superior durability and long-term performance. This reduces the need for frequent maintenance or repairs, ultimately leading to cost savings over time.

3. Reducing Material Waste & Cost

Traditional approaches often result in excessive material consumption, leading to increased project costs and environmental impact. Precast detailing services optimize material usage, ensuring that only the required amount of concrete and reinforcement is used.

By planning each component in advance and leveraging precise measurements, precast detailing helps reduce excess raw material waste. This not only makes projects more economical but also promotes sustainable practices by minimizing unnecessary consumption of natural resources.

4. Enhancing Collaboration Through BIM Integration

Collaboration is key to a successful project, and BIM-integrated precast detailing services foster seamless coordination between designers, engineers, and fabricators. With 3D models and digital representations, teams can visualize the entire scope of work before production begins.

This data-driven approach allows professionals to detect potential clashes, make necessary modifications, and improve accuracy before the manufacturing process starts. The result? A smooth workflow that eliminates the guesswork and ensures alignment across all disciplines.

The Role of Digital Transformation in Precast Detailing

The rise of digital tools and automation has transformed precast detailing services, making them more efficient and accessible than ever. With the integration of advanced software solutions, professionals can now create highly detailed, error-free drawings that simplify the entire process.

Some of the key digital innovations influencing precast detailing include:

BIM-based Precast Modeling: A data-rich digital approach that provides a 360-degree view of each precast element, ensuring accuracy in design, manufacturing, and assembly.

Cloud-Based Collaboration: Real-time sharing and updates, allowing teams across multiple locations to work together seamlessly.

AI-Driven Automation: Artificial Intelligence is playing a crucial role in optimizing designs, predicting errors, and suggesting improvements, reducing human intervention in repetitive tasks.

Augmented Reality (AR) & Virtual Reality (VR): These technologies are being used to visualize projects before execution, helping stakeholders understand complexities and make informed decisions.

As digital transformation continues to evolve, precast detailing services will become even more efficient, data-driven, and cost-effective, further solidifying their importance in the AEC sector.

Challenges in Precast Detailing & How to Overcome Them

Despite its many advantages, precast detailing services come with their own set of challenges. However, by implementing strategic solutions, professionals can effectively navigate these hurdles.

1. Coordination Between Multiple Teams

Challenge: Lack of communication between designers, engineers, and manufacturers can lead to discrepancies.

Solution: Using BIM-based collaboration platforms ensures that all teams work with the same data, minimizing misunderstandings.

2. Managing Complex Designs

Challenge: Large-scale projects involve intricate precast components that require precise detailing.

Solution: Leveraging automated design tools helps manage complexity and ensures that every element is accounted for accurately.

3. Adapting to Technological Advancements

Challenge: Rapid advancements in BIM, AI, and automation require professionals to stay updated with the latest tools and trends.

Solution: Investing in ongoing training and upskilling ensures that teams remain competitive and proficient in using modern technology.

The Future of Precast Detailing in the AEC Industry

Looking ahead, precast detailing services will continue to evolve as technology advances and new methodologies emerge. The adoption of AI-driven modeling, cloud-based workflows, and automated fabrication will redefine how precast elements are designed, produced, and implemented.

With the increasing demand for sustainability and efficiency, precast detailing will remain at the forefront, helping professionals deliver projects faster, reduce costs, and enhance overall quality.

Conclusion

From streamlining workflows to enhancing precision and sustainability, precast detailing services have become an integral part of the modern AEC industry. As the field continues to embrace digital transformation, these services will play an even greater role in shaping the future of architectural and engineering excellence.

Would you like to explore how Silicon Engineering Consultants Pty Ltd can assist with high-quality Precast Detailing Services? Reach out today and let’s collaborate on your next project! 🚀

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.