How Safe Are Laser Engraving Services? Facts You Need to Be Aware Of

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

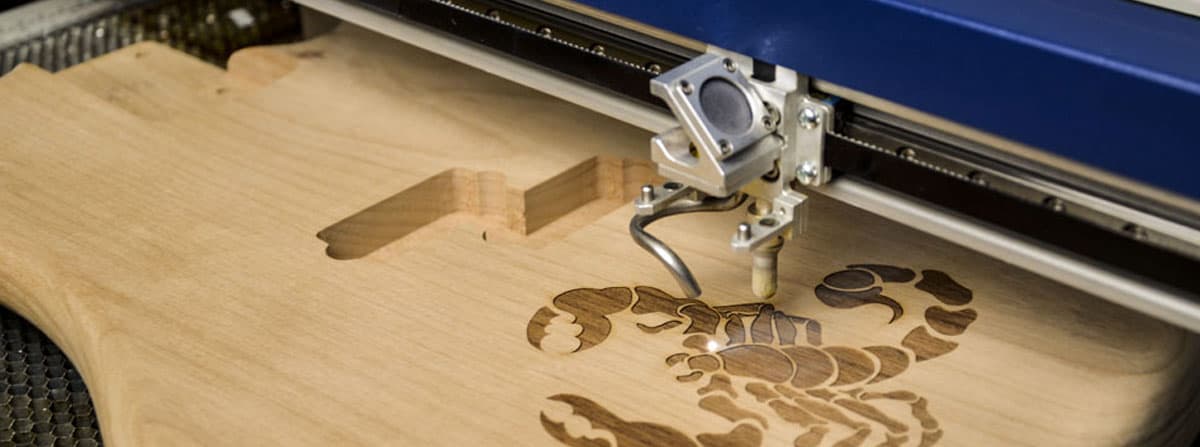

Individuals and businesses rely on laser engraving for personalization, intricate designs, and creative expression. Medford Laser Engraving Services are precise, efficient, and versatile for various materials like wood, acrylic, metals, and glass. Furthermore, for a good reason, laser technology is exact, efficient, and quite flexible when working on materials ranging from wood and acrylic to metals and glass.

Still, laser engravers have their safety issues, much as any tool or machine would. As with the proper volume settings for a white noise generator, it is essential to understand the possible hazards and best practices for laser engraving machines.

Safety First with Laser Engraving Services

Although laser engraving is somewhat familiar, safety should always come first.

"The capacity for precision and speed that laser engraving provides is unrivaled," says Dr. Megan Thompson, an occupational safety specialist at a top university research center. Still, such power comes with responsibility. Laser beams can create fumes and particles that could be dangerous if breathed when they come into touch with some substances.

"Most people concentrate on the creative aspects of laser engraving," Thompson notes, "and don't always think about adequate ventilation, protective gear, or the possibility for harmful exposure." Crucially, it is awareness.

Appropriate ventilation is crucial to reduce these hazards. A well-made exhaust system with filters may help draw airborne pollutants away from the operator and the surroundings.

Eye and skin hazards

Laser beams are very focused sources of heat and light. Direct exposure—or even reflected beams—may compromise your vision. This is why many manufacturers advise (or even demand) laser safety eyewear, especially rated for the wavelength of the laser.

Should your skin come into touch with the beam, there is also little chance of skin burns or discomfort.

Overheat Risk and Fire

Lasers produce high degrees of heat, which can be a fire danger under some circumstances, such as running a poorly maintained machine or etching volatile materials. Medford Laser Engraving Services takes necessary precautions to reduce the possibility of mishaps, including routine equipment checks, cleaning, and never leaving an engraving machine unsupervised.

Professional Advice on Riskless Operation

Guidelines for operating laser equipment exist at the Occupational Safety and Health Administration (OSHA) and the Laser Institute of America (LIA). Although certain laser classes and power levels affect these guidelines, generally, the concepts are:

• Maintain Your Space: Maintain a safe operating distance throughout equipment use. Whenever feasible, use cages or protective obstacles.

• Use appropriate personal protective equipment: Crucially, you need goggles matched to the wavelength of your laser. Sometimes, respirators or face masks are advised to prevent inhaling harmful vapors.

• Guarantee correct ventilation: Local exhaust ventilation or a well-sealed enclosure with a connected filtration system will guard operators and onlookers.

• Watch machine settings: There are ideal speed and power settings for laser engravers to ensure safety and lower dangerous emissions, just as suggested decibel levels for white noise machines protect your hearing.

"Although there is no one-size-fits-all safety rule, be sure the enclosure of your equipment is correctly sealed. John Smith, a safety engineer with a commercial manufacturing company, remarked, "Those systems must be in top shape whether they call for air assist or water cooling." "Minor oversights can cause major problems downstream."

An Actual Case Study: Sparks in the Workshop Case Study:

A modest Colorado woodworking company decided in 2022 to add laser engraving to customize coasters and cutting boards for nearby clients. At first, everything went well. Orders were filled, production was high, and clients enjoyed the personalized goods. However, the owners did not pay close attention to a crucial safety precaution. The chamber's ventilation system was antiquated, and some recently built exhaust ducts were partially clogged by trash.

The blocked exhaust left smoke lingering in the laser engraving region for several months, causing too much tiny particulate matter to accumulate on surfaces. One evening, whilst carving a set of wooden coasters, a stray spark set off the gathered dust next to the air assist nozzle. The little spark set off the fire alarm in the workplace by becoming a flame.

Fortunately, the staff swiftly doused the fire by following the emergency plan. Nobody was injured, and there was just minor physical damage. This episode, nevertheless, was a wake-up call. Further investigation showed that the fire risk might have been much lower with regular checking and appropriate ventilation.

Key Learnable: Even a small neglect in cleanliness or ventilation may raise the danger of an otherwise well-regulated process. This emphasizes the need of Medford Laser Engraving Services for frequent inspections, consistent equipment maintenance, and compliance with rigorous safety standards.

Helpful Advice to Maintain Laser Engrave Safety

Select the Correct Tool: Search for reliable brands with built-in ventilation vents and enclosed laser cabinets, which are safety elements.

Adopt Manufacturer Advice: Every machine has particular instructions on perfect speed and power levels.

Laser overloading can cause excessive heat production. Invest in suitable exhaust or filtration systems, whether you operate a professional shop or work from home.

Put on protective gear: At least wear laser safety goggles. Consider a respirator or face mask if you are engraving materials that emit fumes.

Maintain Its Cleanliness: Clean the laser bed and adjacent regions often of dust, trash, and residue. This enhances engraving results and lowers fire danger.

Stay close while the equipment is operating. Never leave it unattended. Should a small issue surface—such as an odd spark or a jam—you can quickly handle it.

Plan a regular maintenance schedule: Review mirrors, lenses, ventilation systems, and filters. Replace or clean items according to the manufacturer's recommended schedule.

Thoughts on Final Notes

Laser engraving services provide a fantastic array of options for industrial, artistic, and personal endeavors. However, Medford Laser Engraving Services demand careful safety precautions, just as you would pay attention to volume settings for a white noise machine to save your hearing. Laser engraving may be safe and effective with the proper care—ventilation, safety clothing, and routine maintenance.

Thompson advises anyone worried about fumes or laser exposure to "talk to an expert or research recognized guidelines." Adjustments to your setup can make all the difference between excellent, long-term performance and a potentially hazardous scenario.

Just as you would turn down the white noise machine to a safe decibel level to prevent major blunders, ensuring your laser engraver is running under-regulated settings will also help you avoid major mistakes. Watch Goldsmiths Diamonds & Design for safety, keep educated about new best practices, and appreciate the amazing powers laser engraving offers for your personal or business tasks.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.