How SDA Bolt is Ensuring Safety and Stability in Structural Design

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In modern construction and infrastructure development, safety and stability are more than technical standards—they’re the foundation of success. As structures become taller, tunnels go deeper, and ground conditions grow more challenging, engineers are turning to proven solutions like the SDA Bolt to meet demanding performance requirements.

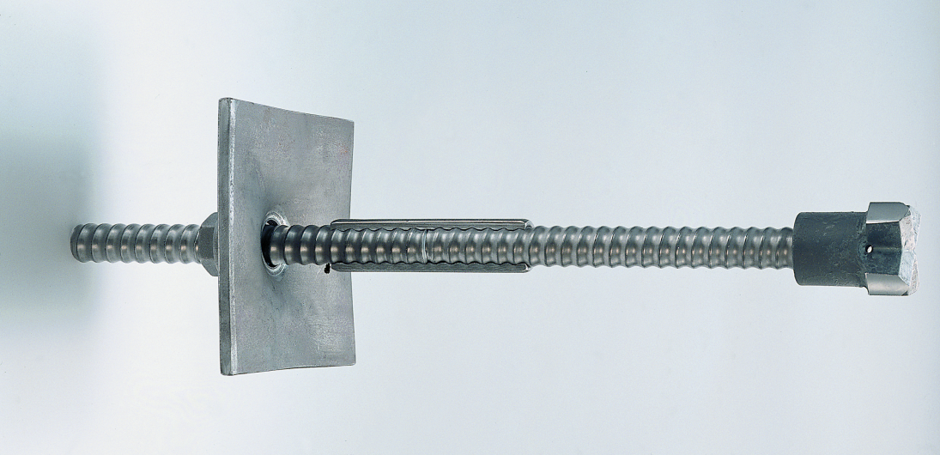

Short for Self-Drilling Anchor, the SDA Bolt is a highly effective system designed to provide immediate ground support in challenging environments. Its unique ability to drill and anchor in one operation has made it a preferred choice for geotechnical and structural engineers worldwide.

What Makes SDA Bolt Different?

The SDA Bolt combines a threaded hollow steel bar with a sacrificial drill bit. As it’s installed, the bolt drills into the ground while allowing grout to be injected through the hollow core, bonding the system to the surrounding strata. This eliminates the need for pre-drilling or casing, streamlining the installation process and improving structural integrity from the start.

1. Reliable in Unstable Ground Conditions

In construction projects involving loose soils, fractured rock, or water-logged terrain, achieving secure ground support is often difficult. Traditional anchoring systems can struggle to stay in place or lose their effectiveness due to hole collapse.

The SDA Bolt provides an immediate solution. Its self-drilling capability stabilizes the ground during installation, while the grout seals and secures the bolt in place. This makes it especially valuable for slope stabilization, tunnel walls, and deep excavations.

2. Faster Installation with Fewer Steps

Time savings are critical in today’s construction schedules. The SDA Bolt significantly speeds up the reinforcement process by eliminating the need for separate drilling and anchoring steps. With a single piece of equipment, the bolt is drilled and grouted simultaneously, reducing labor requirements and equipment use.

This streamlined process helps projects stay on schedule—even in the face of tight deadlines or difficult conditions.

3. High Load-Bearing Strength

Whether supporting a tunnel wall or anchoring a retaining structure, strength matters. The SDA Bolt is engineered to handle high tensile and shear loads. Its full-length bond with the surrounding grout provides reliable, long-term support even in aggressive environments.

With various diameters, thread types, and drill bits available, the SDA Bolt can be tailored to meet the specific load and soil conditions of any project.

4. Versatility Across Applications

From underground metro systems to mountainous road construction, the SDA Bolt has proven its value across a wide range of projects. Its adaptability to different angles, depths, and ground types makes it a go-to solution for engineers handling complex designs.

Common uses include tunnel lining support, foundation reinforcement, retaining wall anchoring, and temporary support in deep excavations.

5. Safer Work Environments

Fewer steps in installation mean fewer opportunities for errors or accidents. The SDA Bolt enhances workplace safety by reducing manual handling, minimizing time spent in hazardous zones, and offering immediate support as drilling progresses.

This added safety factor is particularly important in underground and confined workspaces where worker protection is a top priority.

6. Long-Term Durability

For permanent structures, reliability over decades is non-negotiable. The SDA Bolt can be manufactured with corrosion-resistant coatings such as galvanizing or epoxy finishes, extending its life in aggressive or moist environments.

Its consistent performance over time reduces the risk of structural degradation and ensures the safety and integrity of infrastructure investments.

7. Lower Overall Project Costs

While the SDA Bolt may have a higher initial material cost, the overall savings in time, labor, and equipment can significantly reduce total project expenses. Faster installations and reduced maintenance contribute to long-term cost efficiency.

This is especially beneficial on large infrastructure projects where thousands of anchors are required.

8. Compatibility with Modern Equipment

Construction sites today are equipped with advanced machinery and precision tools. The SDA Bolt system is fully compatible with hydraulic drilling rigs and modern grouting systems, making it easy to integrate into any workflow.

Its adaptability ensures consistency, quality control, and better project management.

Conclusion

Structural stability is the backbone of every safe and successful construction project. With its proven ability to reinforce unstable ground, accelerate installation, and deliver long-term performance, the SDA Bolt has become a trusted solution across the construction and mining industries.

For those seeking dependable anchoring systems built for today’s toughest engineering challenges, Argentium offers high-quality SDA Bolts designed to deliver both safety and strength—ensuring your structures stand the test of time.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.