How To Find a Customizable Silicone Foam Gasket?

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

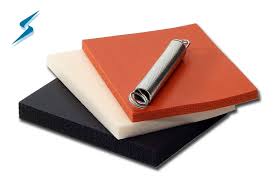

The industrial sealing solutions sector has advanced significantly driven by the innovations in silicone foam string and custom made silicone foam gaskets that become part and parcel of more and more applications. Whether it is in the automotive field or HVAC systems or electronics or general manufacturing, all would agree that these high-performance sealing materials surpass traditional materials when it comes to reliability, flexibility, and durability.

Let's talk about what makes silicone foam string so valuable and customizable gaskets and why many industries are jumping on the bandwagon.

What Is Silicone Foam String?

Silicone foam string, also known as silicone sealing foam cord, is defined as a flexible, closed-cell material produced through extrusion into a continuous string or cord form. It is a very effective air-water-dust and even a few chemicals proof material beneath closed-cell construction. Compared to a solid rubber or standard foam, silicone foam string combines compressibility and a tough structure, making it very well suited for sealing and barrier purposes in confined spaces.

It is extremely lightweight like a sponge and therefore has the characteristics of good cushioning, heat insulation, and shock absorption, plus the heat and weather resistance everyone associates with silicone.

Best Benefits of Silicone Foam String

Weather-Stripping Silicone, as naturally called silicone, works against extremes, UV rays, and ozone. There is no sign of cracking or degrading in other unfavorable outdoor conditions. Thus, it is advisable for a long time for both indoors and outside places for best use.

Customizable Silicone Foam Gasket

Thermal Insulation

It is one of the most common insulators in the requirements of temperature differences, such as electric power underground enclosures inside air conditioning.

Water and Dust Seal

The closed-cell structure impermeable to air moisture and dust makes it a perfect weatherstrip or seals enclosures from the outside elements.

Flexibility and Easy Installation

With different diameters, silicone foam string is easy to cut to size and bent or shaped to accommodate complex gaps- easy installation and custom-making.

What is a Custom Silicone Foam Gasket?

As the name indicates, a customizable silicone foam gasket is an adaptation for the specific requirement of having its dimension, shape, thickness, or density made up to specification according to the needs with precision. Unlike stock gaskets available in the mass market, customizable gaskets are tailored for specific measurements and performance requirements defined by your application.

These are usually cut from a silicone foam sheet or taken in extruded cords, and they can also come with self-adhesive backing, different ranges of hardness, or even multi-layered, depending on their application.

Why Choose Customizable Silicone Foam Gaskets?

Precision Fit

Every sealing problem is unique. Customizable gaskets will ensure precision fit for your components whether you need a flat sheet, a complicated shape, or a gasket with bolt holes and cut-outs.

Material Control

Control under different densities, colours, and grades of silicone foam is made to make it fit into the environment requirements-whether it is fireproof, high-temperature resistant, or chemically compatible.

Greater Sealing Performance

A perfectly fitting gasket is not likely to leak, break, or move over time, thus enhancing the functionality and lifespan of your equipment sealed in this way.

Cost-Benefit in the Long Run

Custom solutions tend to cost a higher amount right at the beginning, but they do away with the repairs, around-the-clock downtime, and replacement costs over a period of time.

Environmental and Safety Benefits

Silicone foam products are manufactured concerning environmental standards for halogen-free, non-toxic, and low VOCs. Many of them also sport flame retardant properties and comply with safety regulations from the use of these materials in sensitive or high-risk areas, such as in medical devices or on public transport.

Final Thoughts

Silicone foam string and Customizable Silicone Foam Gasket could stake a rightful claim for the future of sealing technology. With flexibility, resilience, and adaptability beyond compare, these materials are setting the trend among industries for enhancing performance while cutting down on maintenance and energy costs.

Whether you need a run-of-the-mill sealing solution or want high-precision custom gaskets for a critical component, silicone foam materials have you covered. Plus, with custom products, you can expect your application to perform smoothly, safely, and for the long haul.

Wanting to improve your sealing system? Select silicone foam, and the difference shall speak for itself in performance and serenity!

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.