How to Handle Corrosive Chemicals Safely with Centrifugal Pumps

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Handling corrosive chemicals requires for a complete understanding of both the substances included and the gadgets used. This summary plans to supply a considerable introduction of just how to firmly relocate damaging chemicals utilizing centrifugal pumps, seeing to it the safety of employees and the stability of the items.

Understanding Corrosive Chemicals

Corrosive chemicals are materials that can trigger problems or damage to products upon telephone call. They typically have acidic or caustic homes, positioning substantial risks to both human health and wellness and wellness and the setting. Normal examples include sulfuric acid, hydrochloric acid, and sodium hydroxide.

When working together with these hard substances, it is really to address common challenges and solutions with thermic fluid pumps, as these pumps need to be carefully picked and protected to handle heats and harmful liquids. Making sure appropriate product choice, normal analyses, and keeping ideal fluid levels are vital to decrease risks and assure the pump's stability and lengthy life. This is particularly genuine when dealing with a thermic fluid pump as these pumps handle heats up and potentially corrosive liquids.

Characteristics of Corrosive Chemicals

Corrosive chemicals are typically specified by:

- Low pH (for acids) or high pH (for bases).

- Capacity to set off quick material destruction upon get in touch with.

- Possible for releasing damaging fumes or gases.

Common Type of Corrosive Chemicals

1. Acids:

- Sulfuric Acid (H2SO4)

- Hydrochloric Acid (HCl)

- Nitric Acid (HNO3)

2. Bases:

- Sodium Hydroxide (NaOH)

- Potassium Hydroxide (KOH)

- Ammonium Hydroxide (NH4OH)

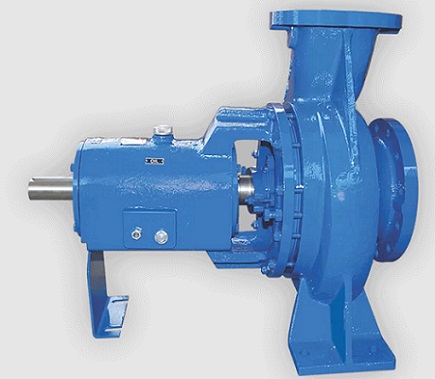

Overview of Centrifugal Pumps

Centrifugal pumps are a recommended option for chemical transfer due to their performance and convenience. They work on the concept of using a transforming impeller to impart power to the fluid, raising its speed and anxiety. For applications calling for greater tension, what is a multistage centrifugal pump and how does it work? These pumps consist of numerous impeller phases that interact to considerably boost the fluid pressure, making them perfect for high-pressure applications such as water supply, business processes, and chemical handling.

Working Principle of Centrifugal Pumps

- The impeller rotates, producing a centrifugal pressure.

- This pressure moves the liquid radially external.

- The liquid gains power and exits the pump at a greater anxiety.

Applications of Centrifugal Pumps

Centrifugal pumps locate significant use in industries such as chemical processing, water treatment, and oil refining for jobs like relocating fluids, improving anxiety, and dispersing fluids. For specific high-pressure applications, vertical turbine pumps work, structure, precautions and tips provide a suitable solution. These vertical centrifugal pump make use of a vertical shaft design with numerous phases to provide high head pressures, making them ideal for deep well applications or systems that require substantial stress and anxiety rises.

Choosing the Right Centrifugal Pump for Corrosive Chemicals

Choosing the perfect centrifugal pump is essential to make sure safe and effective chemical transfer.

Material Compatibility

1. Immune Materials for Corrosive Chemicals

- Stainless steel

- Hastelloy

- Polyvinylidene Fluoride (PVDF)

2. Variables to think about for Gasket and Seal Products

- Viton

- PTFE (Teflon)

Pump Design To Consider

1. Closed Impeller vs. Open Impeller.

- Closed impellers supply greater performance.

- Open impellers are much less vulnerable to obstructing.

2. Shaft Sealing Alternatives.

- Mechanical seals are common for destructive applications.

Installation and Setup

Correct setup is important for the secure treatment of the centrifugal pump when dealing with corrosive chemicals.

Proper Pump Location and Alignment

- Make sure the pump gets on a constant structure.

- Align the pump and electrical motor shafts to prevent vibration and imbalance.

Making Sure Appropriate Inlet Issues

- Give a straight and unblocked course for the liquid to enter the pump.

- Usage appropriate filters or strainers to stop debris from entering into.

Electric and Mechanical Connections

- Make certain electrical connections follow security codes.

- Lubricate and guard all mechanical connections.

Safety Measures during Installation

Offer ample air flow and personal protective equipment (PPE) for employees associated with the installation.

This is particularly important when working together with self priming pumps benefits and downsides you need to understand. While these pumps use the advantage of beginning without the need for a pre-filled fluid, making them ideal for circumstances with changing circulation prices, they likewise feature specific problems such as higher maintenance demands and the opportunity for decreased performance in details issues.

Personal Protective Equipment (PPE)

1. Eye and Face Defense:

- Chemical-resistant safety glasses or face guards.

2. Skin Protection:

- Acid-resistant handwear covers, coveralls, and aprons.

3. Breathing Security:

- NIOSH-approved respirators with appropriate filters.

Emergency Response Plan

1. Spill Control:

- Have spill plans readily offered.

- Establish assigned spill action groups.

2. Emptying Treatments:

- Clearly defined courses and setting up factors.

Spill Response and Cleanup Procedures

1. Isolation:

- Secure the area to stop further contamination.

2. Neutralization and Cleansing:

- Use correct reducing the effects of agents.

- Follow recommended clean-up procedures.

Operation and Monitoring

Ideal treatment and consistent monitoring are necessary for secure chemical transfer.

Starting and Stopping Procedures

1. Steady Start-up:

- Slowly increase the pump to avoid unforeseen stress changes.

2. Emergency situation Closure:

- Ensure workers identify just how to swiftly shut down the pump.

Monitoring Flow Rates and Pressure

1. Pressure Ranges and Flowmeters:

- Install and consistently check tools for exact analyses.

2. Adjustments as Needed:

- Modify setups to maintain optimum circulation prices and tension.

Regular Checks for Leaks and Abnormalities

1. Visual Inspections:

- Look for indicators of leakage, deterioration, or uncommon sounds.

2. Vibration Assessment:

- Monitor for extreme vibration, which could recommend imbalance or wear.

Temperature and Vibration Monitoring

1. Temperature level Sensing units:

- Install to stop obtaining as well hot of the pump.

2. Vibration Evaluation:

- Monitor for uncommon vibration patterns, which might suggest mechanical problems.

Maintenance and Inspection

Regular maintenance is very important for the long life and stability of the centrifugal pump. This typical maintenance guarantees that the pump operates efficiently, minimizing the hazard of downtime or costly repairing.

When it comes to enhancing water supply efficiency with residential pumps, right maintenance of centrifugal pumps is essential to ensuring regular and reliable water blood circulation, making best use of power use, and expanding the life of the system, making them a useful possession for any type of home supply of water system.

Routine Maintenance Schedule

1. Lubrication:

- Follow manufacturer requirements for lubrication periods.

2. Seal and Gasket Checks:

- Inspect for wear, damages, or damage.

Cleaning and Flushing Procedures

1. Chemical Compatibility:

- Use suitable cleaner to do away with harsh deposits.

2. Flushing Systems:

- Implement flushing therapies to clear lines and pump internals.

Compliance and Regulations

Adherence to regulatory criteria is important in caring for severe chemicals. When taking care of high-temperature fluids, how to choose the right thermic fluid pump for your needs comes to be important.

Regulatory Standards for Handling Corrosive Chemicals.

1. OSHA Rules:

- Occupational Safety and security and Health and wellness monitoring standards.

2. EPA Specifications:

- Environmental Security Company referrals for chemical handling.

Reporting and Documentation Requirements

1. File Preserving:

- Maintain substantial records of upkeep, assessments, and occurrences.

2. Coverage:

- Report any kind of sort of events or near misses immediately.

Conclusion

Handling corrosive chemicals safely using centrifugal pumps requires a thorough method. By identifying the chemicals, selecting the ideal tools, using rigorous precaution, and performing regular upkeep, you can ensure a secure and secure and reliable chemical transfer procedure. A centrifugal process pump is vital, as it is particularly made to handle chemicals and liquids with accuracy, ensuring optimum circulation prices and stress while minimizing risks.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.