Link Insertions on Real Blogs – Quick Wins for Better Rankings!

Link Insertions on Real Blogs – Quick Wins for Better Rankings!

How to Leverage Procurement Analysis for Cost Reduction and Efficiency

Written by Tellius » Updated on: November 19th, 2024

In today’s competitive business environment, procurement is more than just purchasing goods and services—it’s a strategic function that can drive significant cost savings and operational efficiency. Leveraging procurement analysis is a key strategy in achieving these goals.

Understanding Procurement Analysis

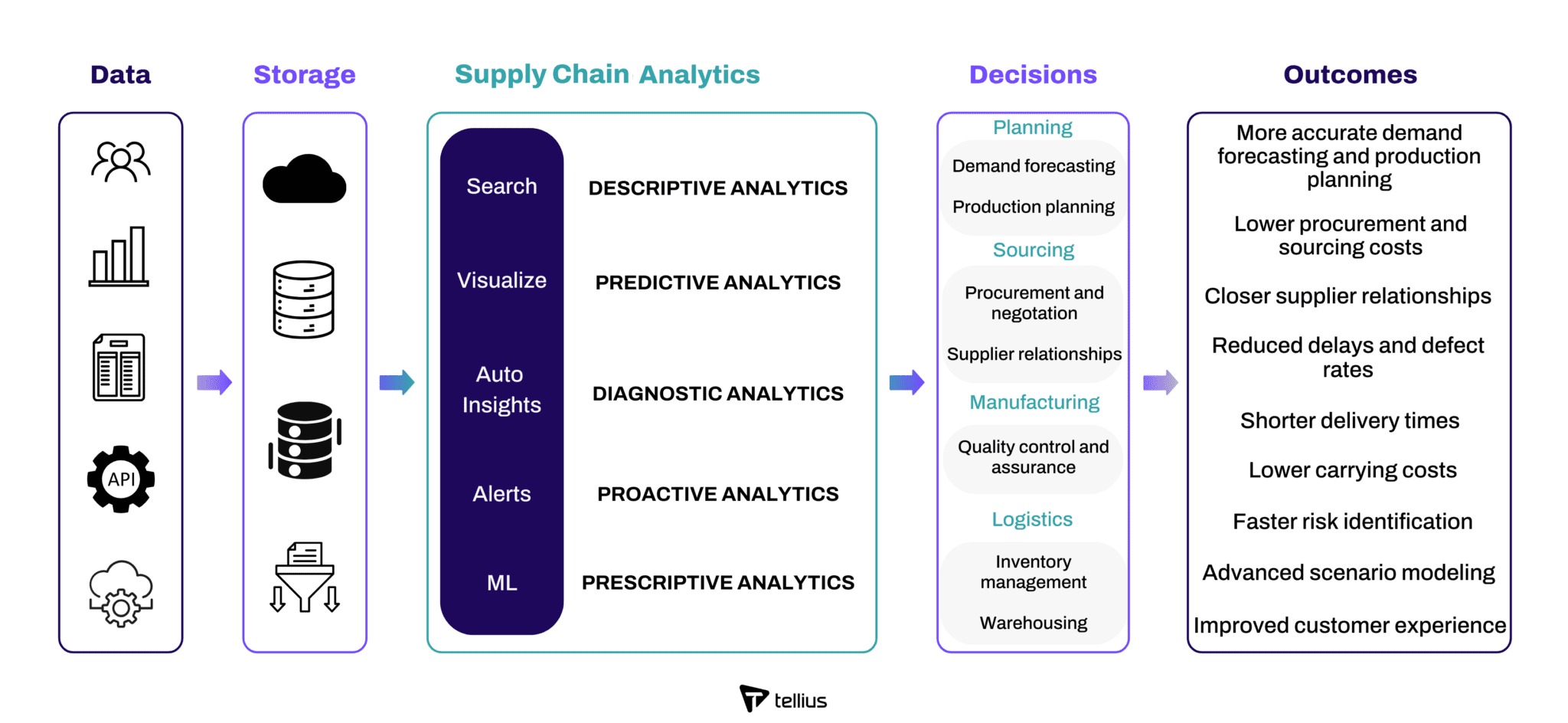

Procurement analysis involves examining and interpreting procurement data to make informed decisions that enhance the value derived from purchasing activities. It encompasses a range of activities, including evaluating supplier performance, assessing purchasing patterns, and identifying opportunities for cost savings. By leveraging procurement analysis, organizations can gain valuable insights into their procurement processes and make data-driven decisions that optimize costs and improve efficiency.

1. Analyzing Spending Patterns

One of the primary ways to use procurement analysis for cost reduction is by examining spending patterns. By analyzing historical spending data, businesses can identify trends and areas where costs are high. For instance, procurement analysis can reveal opportunities to consolidate purchases with fewer suppliers, negotiate better terms, or leverage bulk buying. Understanding spending patterns also helps in identifying maverick spending, where employees bypass approved procurement channels, leading to higher costs. Addressing these issues can lead to more controlled and cost-effective procurement practices.

2. Supplier Performance Evaluation

Effective procurement analysis includes evaluating supplier performance. By assessing metrics such as delivery times, quality, and pricing, businesses can identify which suppliers provide the best value. Regular performance reviews help in maintaining a high standard of supplier service and can reveal opportunities for renegotiating contracts or switching suppliers. Suppliers who consistently meet or exceed performance expectations can be leveraged for better terms, while underperforming suppliers can be replaced or improved upon, ensuring that procurement activities are both cost-effective and efficient.

3. Implementing Strategic Sourcing

Strategic sourcing involves analyzing and optimizing the procurement process to achieve cost savings and efficiency. Procurement analysis provides insights that can guide strategic sourcing decisions, such as selecting suppliers based on total cost of ownership rather than just initial pricing. By considering factors like quality, reliability, and service, businesses can make more informed sourcing decisions that result in long-term savings. Additionally, strategic sourcing can involve negotiating longer-term contracts or partnerships with key suppliers to lock in favorable terms and reduce costs.

4. Leveraging Technology and Automation

Technology plays a crucial role in procurement analysis. Modern procurement software and tools can automate data collection, analysis, and reporting, making it easier to identify cost-saving opportunities. For example, e-procurement systems can streamline the procurement process, reduce manual errors, and provide real-time insights into spending and supplier performance. Automation can also enhance efficiency by reducing the time and effort required for procurement tasks, allowing teams to focus on strategic initiatives rather than administrative work.

5. Forecasting and Demand Planning

Accurate forecasting and demand planning are essential for cost reduction and efficiency. Procurement analysis can help in predicting future demand based on historical data and market trends. By aligning procurement activities with anticipated demand, businesses can avoid overstocking or understocking issues, leading to better inventory management and reduced carrying costs. Forecasting also enables businesses to negotiate better terms with suppliers by providing them with accurate demand projections, leading to cost savings and improved supplier relationships.

6. Continuous Improvement and Benchmarking

Procurement analysis should be an ongoing process of continuous improvement. Regularly reviewing procurement performance and comparing it against industry benchmarks helps in identifying areas for further improvement. Benchmarking against best practices and competitors can provide valuable insights into potential cost-saving strategies and efficiency enhancements. Implementing a culture of continuous improvement ensures that procurement practices remain effective and aligned with organizational goals.

Leveraging procurement analysis is a powerful strategy for achieving cost reduction and operational efficiency. By analyzing spending patterns, evaluating supplier performance, implementing strategic sourcing, utilizing technology, forecasting demand, and focusing on continuous improvement, businesses can optimize their procurement processes and drive significant savings. Embracing these practices not only enhances procurement efficiency but also contributes to overall business success and competitiveness.

Disclaimer: We do not promote, endorse, or advertise betting, gambling, casinos, or any related activities. Any engagement in such activities is at your own risk, and we hold no responsibility for any financial or personal losses incurred. Our platform is a publisher only and does not claim ownership of any content, links, or images unless explicitly stated. We do not create, verify, or guarantee the accuracy, legality, or originality of third-party content. Content may be contributed by guest authors or sponsored, and we assume no liability for its authenticity or any consequences arising from its use. If you believe any content or images infringe on your copyright, please contact us at support@indibloghub.com for immediate removal.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.