8BET Game Download APK

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Download 8Bet Game APK latest version for andriod i pakistan. click the link below to get the latest version of 8bet game apk.

Download 8BET Game.

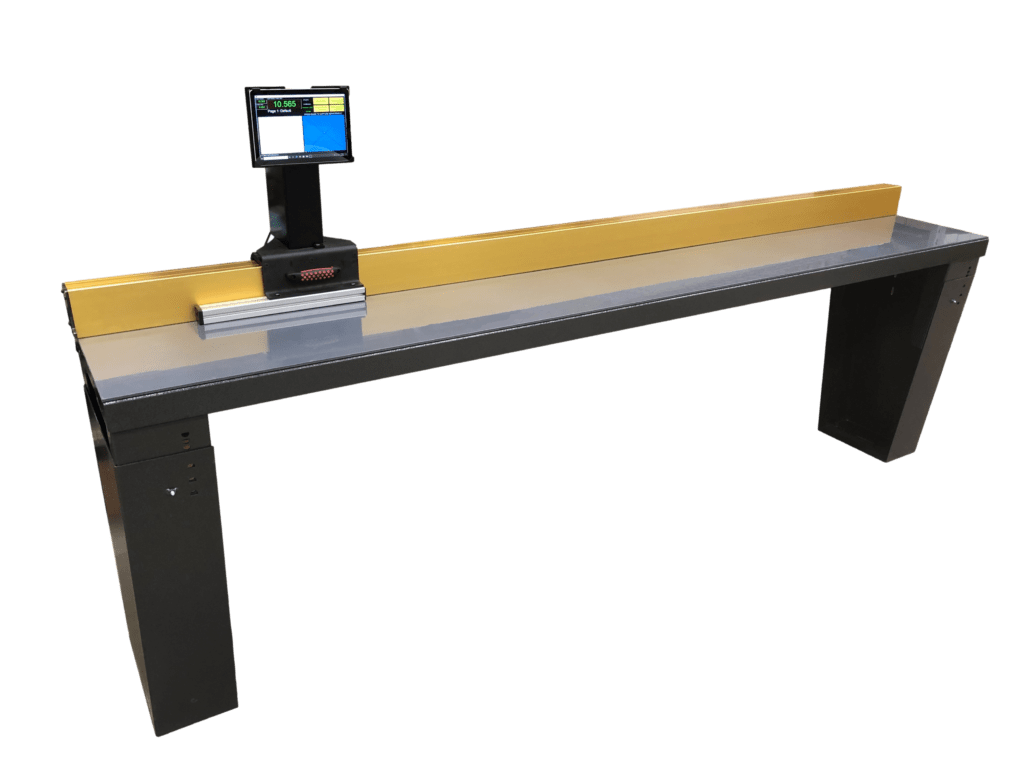

1. Understanding the Purpose of a Length Stop Measuring System

A period-prevent measuring gadget is designed to help users make accurate and repeatable cuts without needing to re-measure fabric each time. Its number one feature is to serve as a mechanical reference factor that stops the material at a fixed length, ensuring each reduction is the equal. This removes the variability related to guide measurement, reducing human blunders and saving time. Before the use of the device, it was crucial to apprehend its additives, including the stop bar, measuring scale, sliding carriage, and locking mechanism. Each component performs a vital role in delivering specific outcomes when used successfully.

2. Setting Up the System Correctly on Your Workbench

Proper setup is important for premiere overall performance. Begin via securely mounting the length prevent measuring machine in your reducing table or workbench. Ensure it is aligned with the slicing blade or device to hold regular measurements. The mounting needs to be co-operative to prevent any movement for the duration of operation. If the gadget includes a rail or music, verify it is parallel to the saw blade to avoid skewed cuts. Take time to double-take a look at alignment with a rectangular or digital perspective gauge. A poorly established system will compromise accuracy, no matter how nicely you operate it later on.

3. Calibrating the Measuring Scale for Precision

Calibration is the next step in using a duration forestall measuring gadget successfully. You must calibrate the measuring scale in order that it reflects authentic cut lengths. To do that, reduce a check piece the usage of the system, measure the piece with a tape measure or virtual caliper, and evaluate it to the preferred measurement. If the measurement is off, adjust the prevent block for this reason until the device fits the actual period. This may additionally take a few attempts, however as soon as the calibration is correct, the device will consistently deliver accurate cuts without in addition adjustments.

4. Adjusting the Stop for Desired Cut Lengths

Once your machine is calibrated, adjusting the stop is easy. Slide the forestall block along the measuring rail on your favored duration and lock it in vicinity. Some systems use manual locking screws even as others may have brief-launch handles for faster operation. It’s crucial to lock the prevent securely to save you from transferring during reducing. For repetitive cuts, write down or mark the settings for normally used lengths, that can save time at some stage in destiny projects. Always double-take a look at the forestall’s function against the size before beginning a manufacturing run.

5. Ensuring Material is Positioned Securely Against the Stop

When feeding fabric into the cutting machine, it's essential to make sure it's far snugly and squarely pressed towards the forestall block. This ensures the cut period is unique. Any hole or attitude among the material and the forestall will result in inconsistent lengths. Hold the cloth firmly in region before activating the cutting device. If your setup allows, recollect the usage of clamps or keep-downs to stabilize longer or heavier materials. Proper positioning prevents slippage and misalignment, each of which could undermine the effectiveness of the measuring device.

6. Making Repetitive Cuts with High Accuracy

One of the best blessings of a period stop measuring gadget is the capacity to make repetitive cuts with uniform accuracy. After placing and locking the forestall, actually feed every new piece of material till it contacts the stop, then proceed with the reduction. This technique eliminates the need to measure whenever, drastically increasing performance at the same time as maintaining precision. It’s best for responsibilities along with reducing more than one boards, tubing, or aluminum profiles to the identical duration. This repeatability improves workflow and reduces waste because of measurement errors.

7. Maintenance and Cleaning to Maintain Accuracy

Routine preservation ensures the sturdiness and accuracy of your measuring machine. Dust, particles, or sawdust can build up at the rails or stop block, affecting motion and accuracy. Regularly wipe down the measuring rail and clean the stop block. If your system has a virtual scale or electronic thing, check for battery existence and recalibrate if wished. Lubricate any moving elements according to the manufacturer’s hints to hold the system working easily. Keeping your measuring system clean and in desirable running order is critical for always correct effects.

8. Troubleshooting Common Issues During Operation

Sometimes, the device won't produce the preferred effects because of common troubles. If cuts are inconsistent, first test that the forestall isn't always shifting in the course of cutting. Re-tighten the locking mechanism if wanted. If measurements seem off, recheck calibration and verify that the measuring scale hasn’t shifted. Check for any warping in the fabric, which can also have an effect on the manner it contacts the prevent. Misalignment among the rail and the cutting tool have to also be corrected straight away. Prompt troubleshooting saves time and forestalls repeated mistakes from affecting your undertaking.

9. Using Accessories to Enhance Performance

To get the maximum out of a length prevent measuring gadget, keep in mind the usage of well suited accessories. Some structures aid extensions, virtual readouts, or upgraded forestall blocks with micro-adjustment abilities. Digital readouts, as an instance, permit for greater specific placing of lengths, while extensions are beneficial for dealing with larger materials. Micro-adjustable stops enable first-rate-tuning of lengths without having to liberate and reposition the entire block. Using these accessories can raise the accuracy and speed of your cuts, mainly whilst working on high-quantity production or distinctive projects.

10. Integrating Technology like an Automatic Pusher System

As industries flow in the direction of automation, integrating advanced systems such as an automated pusher gadget can similarly streamline operations. An automatic pusher system works in tandem with the duration-prevent measuring setup to robotically move and position substances to the suitable length for cutting. This not most effective removes manual feeding however additionally enhances consistency throughout large batches. When linked with digital measuring structures, these pushers can be programmed for numerous reduced lengths, enhancing both speed and accuracy. For organizations or severe hobbyists searching for efficiency, this integration can be transformative. It combines the precision of length forestall measuring with the energy of automation, allowing the person to cognizance of excellence and throughput. Incorporating such systems brings together the pleasantness of mechanical and digital precision, in particular while aiming for repeatable results in a quick-paced production environment.

This complete manual highlights how effective use of a length stop measuring machine can raise your cutting accuracy and efficiency. From setup and calibration to integration with contemporary gear like an automated pusher gadget, getting to know those techniques guarantees expert-grade consequences with minimal attempt.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.