How to Use DTF with Sublimation Ink: A Game-Changer for Cotton Printing

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Sublimation printing has long been the go-to method for vibrant and durable textile transfers—but it's traditionally limited to polyester fabrics. For creators eager to print on cotton or canvas, the need to invest in expensive DTF equipment and switch to pigment inks has been a major roadblock. However, a new technology is bridging the gap: DTF with sublimation ink.

Breaking the Compatibility Barrier

The concept of using sublimation ink on DTF film sounds contradictory at first. Sublimation relies on heat to vaporize dye molecules and infuse them into synthetic fibers, while traditional DTF printing depends on pigment inks bonding with adhesive powder to form a layer on the fabric surface. These differences have made the two systems largely incompatible—until now.

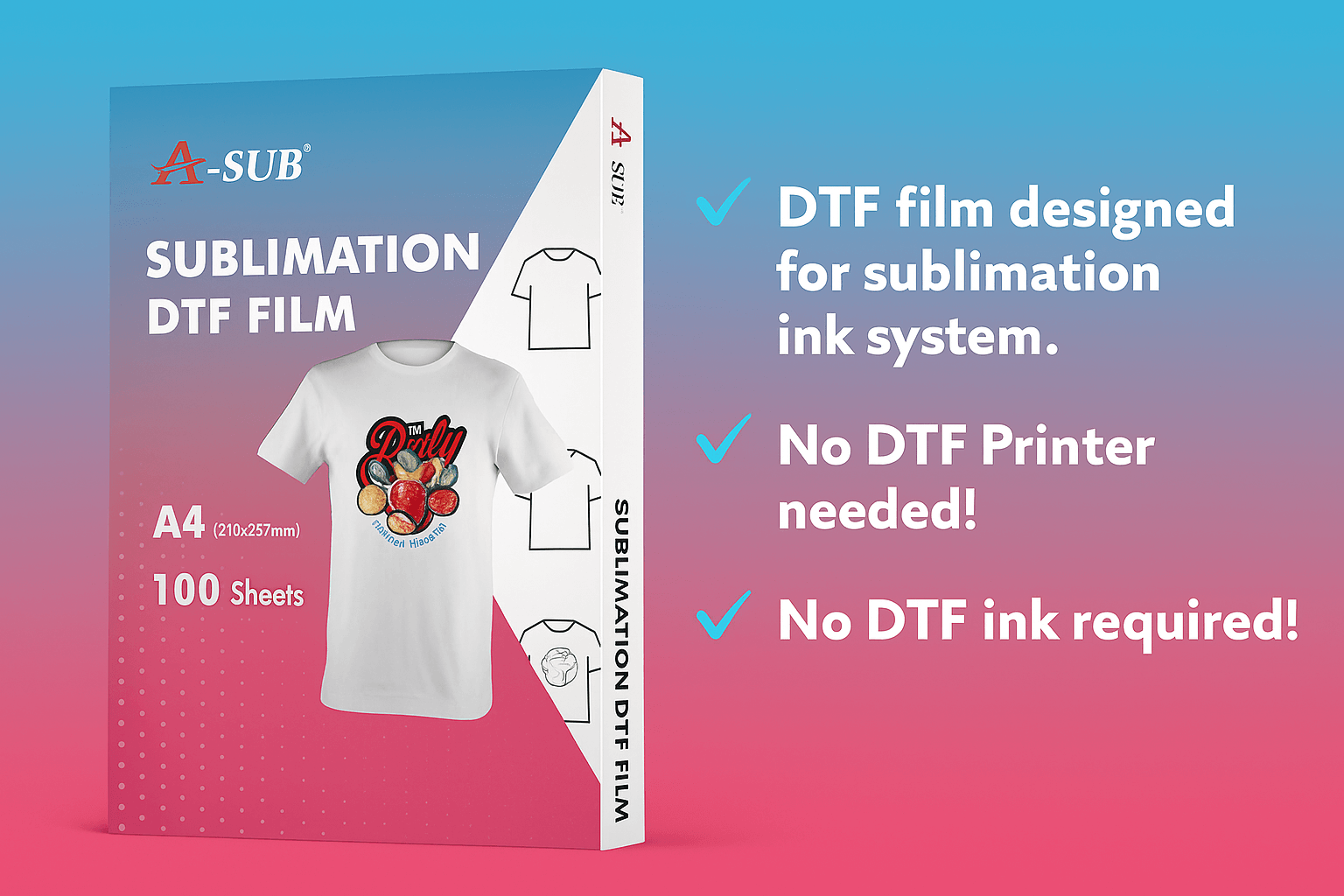

Koala Paper’s latest innovation, a specially engineered sublimation DTF film, changes the equation. It features a dual-layer coating structure that allows sublimation inks to be absorbed and held firmly on the film’s surface, while still supporting powder bonding and heat transfer onto cotton materials. This breakthrough enables users to leverage their existing sublimation printers and inks for a wider range of substrates, without switching ink types or investing in new hardware.

Why Choose DTF with Sublimation Ink?

For many small business owners, educators, and home studio operators, this approach offers the best of both worlds. You retain the color brilliance and fine detail of sublimation printing, while gaining the versatility of DTF transfer. With this method, you can now print on T-shirts, tote bags, pillowcases, and other cotton-based items that were previously off-limits to sublimation.

Better yet, the process is simple and cost-effective. Just print your design on the sublimation DTF film, apply hot melt powder, cure it with a heat press or oven, and then transfer it to your cotton fabric. There’s no need for white ink, RIP software, or large-format DTF equipment. For users of compact sublimation printers like the Epson L8050, it’s a seamless upgrade to your existing workflow.

This also opens the door to personalization for a wider audience. Crafters working from home can now create custom cotton gifts like aprons, baby clothes, or family T-shirts. School art programs or design classrooms can offer hands-on experience with textile decoration using affordable tools. Even small promotional product vendors can respond quickly to client needs without heavy investment.

Superior Output and Eco-Friendly Design

Koala Paper’s sublimation on DTF film also delivers impressive print results. Thanks to its nanoporous absorption layer, designs come out with vivid color, high resolution, and strong resistance to washing and cracking. The release layer ensures clean peeling after transfer, making the process easier and more efficient—even for beginners.

In real-world use, this means fewer errors during production, smoother workflows, and more consistent output—critical factors for small operations that can’t afford waste or delays. For those previously frustrated by blurry lines or ink smudging when experimenting with DTF, this film solves the problem with clean, crisp edges and durable prints.

From an environmental perspective, the product aligns with Koala Paper’s commitment to sustainable production. It uses low-energy coating techniques and passes multiple safety certifications, ensuring that high performance doesn’t come at the cost of ecological responsibility.

The water-based coating system used in Koala Paper’s production process reduces the use of harsh solvents, while the recyclable PET base film further supports circular economy goals. Whether you’re a conscious consumer or a brand looking to reduce its footprint, this product delivers peace of mind alongside professional output.

Expand Your Creative Possibilities

Whether you're running a small T-shirt business or teaching design techniques in a classroom, switching to DTF with sublimation ink can significantly expand your creative output without increasing operational burden. This technology removes the limitations of traditional sublimation printing and gives you access to a whole new world of cotton and blended materials.

As interest in personalization and handmade goods continues to grow, being able to print vibrant, long-lasting designs on diverse fabrics gives you a competitive edge. With just a few basic tools, you can offer high-quality, full-color prints on garments that would previously require complex screen printing or costly DTF systems.

If you’ve been wondering how to print on cotton using sublimation, this is the answer. Koala Paper’s film is available now, and sample requests are open for users who want to test it firsthand.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.