Indonesia Additive Manufacturing Market: Strategic Initiatives, Emerging Innovations, and Developments

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Introduction:

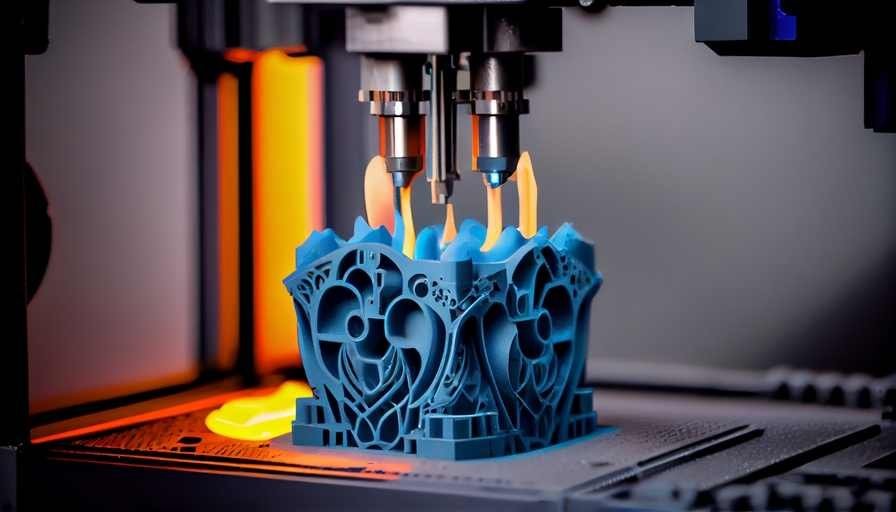

The Indonesia Additive Manufacturing Market is experiencing rapid growth, driven by strategic government policies, technological innovations, and industry collaborations. In recent years, the market has garnered attention from a diverse range of industries, from construction to aerospace, as companies look to leverage advanced manufacturing technologies to improve productivity and reduce costs.

Strategic Government Initiatives

The Indonesian government has been instrumental in the expansion of the additive manufacturing industry through strategic initiatives that support innovation and technological adoption. The "Golden Indonesia 2045" vision, an ambitious plan to position Indonesia as a leading industrial hub, aims to elevate the manufacturing sector’s contribution to the national GDP to 28%. To achieve this, the government is actively encouraging the use of advanced manufacturing technologies, including additive manufacturing, which promises to improve efficiency and competitiveness across industries.

One of the most notable initiatives is the collaboration between Indonesia’s Bakrie Group and COBOD International, a global leader in 3D construction printing. This partnership has led to the establishment of PT Modula Tiga Dimensi, which focuses on revolutionizing the construction sector through 3D printing technology. This collaboration aims to create environmentally friendly, cost-effective, and innovative building solutions using 3DCP (3D construction printing). By incorporating additive manufacturing into the construction process, Indonesia is positioning itself as a trailblazer in the use of 3D printing for large-scale, sustainable building projects.

Technological Innovations and the Role of AI

Technological advancements are a key driver behind the growth of Indonesia’s additive manufacturing market. One of the most significant innovations is the integration of artificial intelligence (AI) into 3D printing processes. AI plays a crucial role in optimizing the additive manufacturing workflow by analyzing vast amounts of data generated during the printing process. These datasets include critical variables such as material properties, printing parameters, and environmental conditions. AI uses this data to enhance the quality of the printed product by identifying patterns, suggesting optimal settings, and predicting potential defects before they occur.

This integration of AI leads to improvements in production quality, a reduction in material waste, and the acceleration of manufacturing timelines. Moreover, it provides manufacturers with the flexibility to produce customized products tailored to specific customer needs. In Indonesia, where customization and precision are becoming increasingly important in sectors such as aerospace, automotive, and healthcare, AI-enhanced additive manufacturing presents a competitive edge in a rapidly evolving global market.

Collaborative Efforts Across Industries

Collaboration between various stakeholders, including government bodies, private enterprises, research institutions, and universities, is essential for driving the growth of additive manufacturing in Indonesia. These partnerships foster an environment of innovation and technological exchange that is crucial for overcoming the barriers to adoption faced by smaller businesses. Strategic alliances allow companies to pool resources, share knowledge, and reduce the financial risks associated with investing in new technologies.

A prime example of such collaboration is the partnership between local manufacturers and international AM companies that provide cutting-edge 3D printing technology. These collaborations are crucial for scaling production capabilities and ensuring that businesses in Indonesia have access to the latest advancements in additive manufacturing technology. Furthermore, these partnerships promote workforce development, ensuring that the next generation of engineers and technicians are trained to operate and maintain advanced 3D printing systems.

Market Challenges and Financial Barriers

Despite its promising growth prospects, the additive manufacturing market in Indonesia faces several challenges that may hinder its expansion. The most significant challenge is the high upfront investment required for the acquisition of 3D printers, materials, and skilled labor. For many smaller businesses, the initial costs can be prohibitive, limiting their ability to enter the additive manufacturing sector or scale their operations. Additionally, the lack of access to affordable financing options and the relatively high costs of consumables pose further barriers to widespread adoption.

To address these financial barriers, it is essential for both government and industry stakeholders to provide incentives and subsidies that make additive manufacturing more accessible to a broader range of businesses. By reducing the financial risk associated with new technology adoption, the government can encourage more companies to explore the benefits of additive manufacturing.

Future Outlook and Growth Opportunities

Looking ahead, the Indonesian additive manufacturing market is poised for significant expansion, supported by ongoing technological innovations and government-backed initiatives. As companies across industries begin to realize the potential of additive manufacturing, the market is expected to diversify, with applications extending to sectors such as automotive, aerospace, healthcare, and consumer goods. The integration of AI and other digital technologies will continue to drive improvements in manufacturing efficiency, while the growing demand for customized, on-demand products will further fuel the adoption of 3D printing.

Indonesia’s commitment to sustainability and eco-friendly manufacturing processes positions the country as a potential leader in the green manufacturing movement. Additive manufacturing's ability to reduce waste, optimize material usage, and lower energy consumption aligns with Indonesia’s long-term environmental goals, making it a key player in the future of sustainable manufacturing.

Access Full Report: https://www.nextmsc.com/report/indonesia-additive-manufacturing-market

Conclusion

The additive manufacturing market in Indonesia is on a promising growth trajectory, driven by strategic government initiatives, technological innovations, and collaborative efforts across industries. With the support of AI and 3D printing technologies, the country is positioning itself as a leader in advanced manufacturing, especially in sectors such as construction, aerospace, and healthcare. While financial barriers remain a challenge, the government’s efforts to promote the integration of additive manufacturing into the industrial landscape are creating new opportunities for businesses of all sizes. As the market continues to evolve, Indonesia is set to become a major player in the global additive manufacturing industry, contributing to the development of innovative manufacturing solutions and sustainable industrial practices.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.