Innovative Trends in Cold Store Panel Design for 2025

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Preserving perishable goods at ideal temperatures represents an essential foundation for food industry operations, pharmaceutical distribution services and logistics infrastructure. Modern technological improvements coupled with increasing environmental concerns have brought substantial changes to cold store panel design. Industry trends during 2025 have transformed cold storage construction processes through efficient, environmentally friendly, advanced technological solutions. This blog showcases the primary advancements in cold store panel design along with ways these advancements deliver solutions for contemporary industrial needs.

Enhanced Insulation Materials

Cold store panels rely on insulation materials as their essential component because these materials directly influence both energy efficiency and temperature regulation capabilities. Current manufacturers utilize two advanced insulation materials named vacuum-insulated panels (VIPs) together with aerogels in 2025. Modern insulation materials demonstrate better thermal protection abilities when compared to standard polyurethane or polystyrene foam applications.

The reduced heat exchange capabilities of VIPs allow temperature stability for extended durations using less applied energy. Aerogels maintain both their weight advantages and excellent insulation capabilities, which drives their use in new hybrid panel systems.

Research and Development of Adaptable Modular Panels

Protecting our environment through operational flexibility is a must for contemporary businesses, together with facilities that require cold storage. The modular design of cold store panels presents itself as the top choice for 2025 due to their rapid construction potential and adjustable storage areas that businesses can easily resize or change according to their needs.

The versatility of panel design options permits businesses to create cold storage facilities that meet their special requirements for temperature zones and storage organization. Pre-engineered modular solutions accelerate construction timelines while companies fulfill all relevant industry standards.

Sustainability and Eco-Friendly Designs

Global industries focus intensely on sustainability while cold storage systems also drive this focus worldwide. In 2025, cold store panel production focuses upon developing environmentally responsible materials and sustainable production methodologies. The building industry shows interest in two types of panels: recycled material panels, alongside blowing agents offering low global warming potential (GWP), are starting to replace traditional building materials.

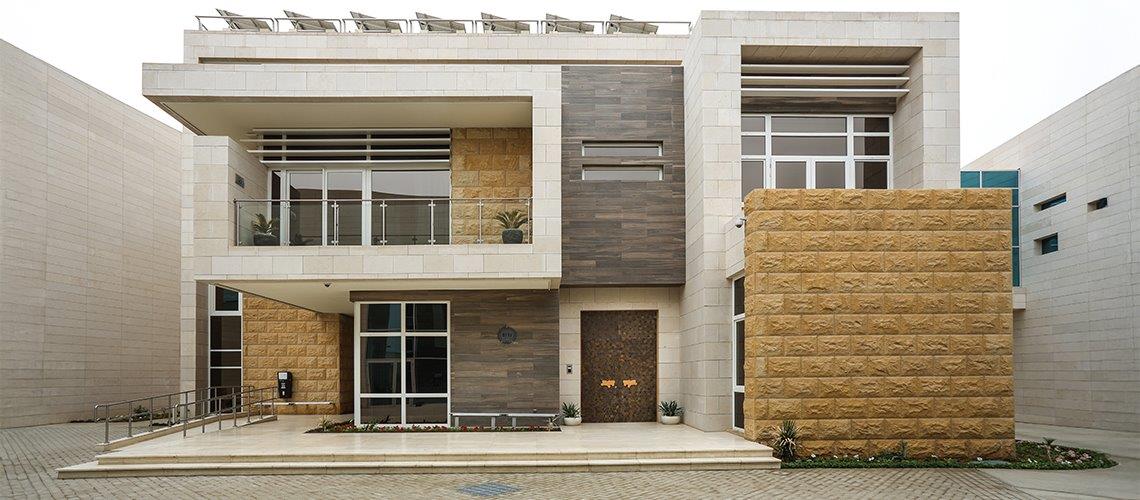

The transition to renewable energy has become increasingly popular because cold storage facilities now use solar panels and other renewable energy technologies for their power needs.

Integration of Smart Technologies

The cold store panel design landscape has welcomed solutions enabled by the Internet of Things (IoT) alongside its smart technology developments. Building technologies in 2025 include established sensor systems that continuously measure temperature along with humidity while tracking panel energy usage.

Driveway sensors monitor critical storage parameters to generate alerts on impending issues such as air leaks alongside insulation failure before major problems take hold. Devices installed within some systems create unified interfaces to monitor storage spaces and supply system performance information, which helps decrease operational expenses and enhance storage quality.

Aesthetic and Functional Improvements

Functional excellence remains essential, but the cold store panels from 2025 demonstrate improved design along with functionality. The contemporary cold storage system presents advanced designs that integrate smooth-finished panel systems to provide a durable and professional appearance. Favorable adoption across food processing and pharmaceutical facilities has been observed for anti-bacterial coatings and easy-to-clean surface applications.

The Future of Cold Store Panels

The evolution of cold store panel design throughout 2025 presents a blueprint of industry changes that emerged to address growing demands regarding operational efficiency and sustainability, plus technological needs. New insulation solutions reduce operational expenses while sustaining product consistency. Construction processes benefit from modular and customizable solution systems. Smart technology and sustainability initiatives drive cold storage facilities toward eco-friendly yet connected sustainable solutions.

Conclusion

The continued evolution of cold store panel design stands as the primary force in satisfying industry demands for quality and safety alongside innovative solutions. Cold storage facility developers need to adopt these market trends as a fundamental requirement to command competitiveness in today's modern business environment. If you want to know more about these types of panels, then visit TSSC Group's official website.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.