Key Factors to Consider When Choosing Sheet Metal Fabrication Design Services

Selecting the appropriate sheet metal fabrication design services is a vital step that can significantly influence the success of your manufacturing project. The design phase sets the foundation for quality, cost-efficiency, and manufacturability of your final product. Whether you are seeking sheet metal drafting services, sheet metal modeling services, or solidworks sheet metal drawing services, understanding the critical factors involved will help you make an informed decision. This detailed guide explores the key aspects you should evaluate before partnering with a sheet metal design service provider.

1. Expertise and Industry Experience

The cornerstone of reliable sheet metal fabrication design services is the experience and technical expertise of the service provider. A company with extensive experience in sheet metal design outsourcing services understands the nuances of different materials, manufacturing techniques, and industry standards. They are familiar with common challenges and can offer innovative solutions to optimize your design for production. When evaluating potential partners, review their portfolio, client testimonials, and case studies to gauge their proficiency in sheet metal drafting services, sheet metal modeling, and related solutions.

2. Comprehensive Service Offerings

Opting for a provider that offers a wide range of services ensures seamless project management. Look for providers who can handle everything from initial concept design to detailed sheet metal drawings services, 3D modeling, prototyping, and even fabrication consultancy. For example, sheet metal drafting services backed by solidworks sheet metal drawing services allow for highly detailed and accurate designs, reducing errors downstream. Having access to services like sheet metal drawings services, sheet metal modeling services, and sheet metal fabrication design services under one roof simplifies communication, accelerates project timelines, and minimizes misinterpretations.

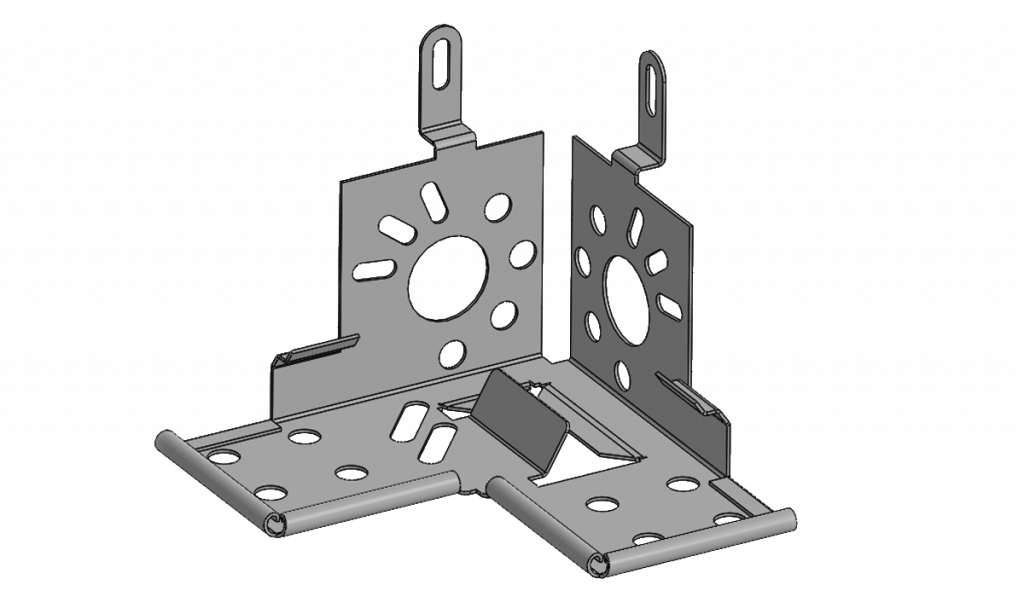

3. Precision, Quality, and Accuracy

In sheet metal fabrication, precision is non-negotiable. Small errors in design can lead to costly issues during manufacturing, such as material wastage, improper fitting, or structural failures. Therefore, it’s crucial to partner with a service provider that emphasizes quality assurance, thorough review processes, and validation of all designs. They should utilize advanced CAD software, such as SolidWorks for creating detailed sheet metal drawings that include bend allowances, punch locations, flat patterns, and assembly instructions. High-quality designs ensure manufacturability, reduce rework, and improve overall product reliability.

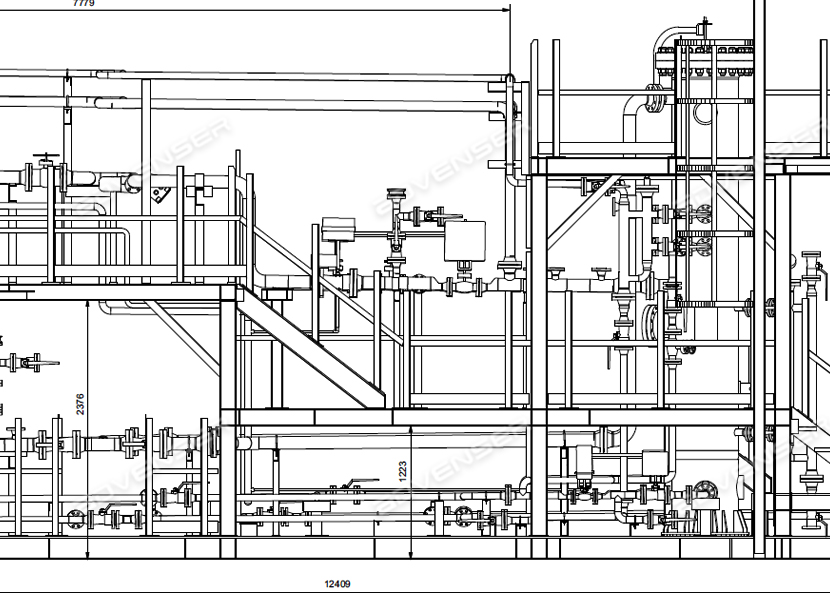

4. Advanced Technical Capabilities and Software Tools

The use of advanced CAD and simulation tools enhances the quality and functionality of sheet metal designs. SolidWorks sheet metal drawing services are particularly popular because they allow engineers to create parametric, easily modifiable models with features like bend tables, punch operations, and flat patterns. These tools also enable simulation of bending, stress analysis, and thermal impacts, which help in predicting how the sheet metal will behave during fabrication and use. Confirm that the provider is proficient in these software tools and employs the latest versions to leverage new features and improvements.

5. Customization and Flexibility in Design

Every project has specific needs, whether it involves unique material choices, complex geometries, or specialized manufacturing processes. Therefore, your sheet metal design partner should offer customization options, allowing you to tailor designs to your exact specifications. Flexibility in accommodating design modifications, material substitutions, and process adjustments is essential to optimize performance and cost. A good service provider will collaborate closely with you, ensuring that your vision is accurately translated into detailed and practical sheet metal drawings and models.

6. Cost-Effectiveness and Turnaround Time

Efficient project execution depends not only on quality but also on timeliness and budget adherence. Providers who can deliver high-quality sheet metal drawings services within your required timeframe can help you meet tight deadlines. Discuss their typical turnaround times and ensure they have the capacity to handle your project volume. Additionally, compare pricing models—some providers offer fixed rates, while others charge hourly or project-based fees. Outsourcing sheet metal drafting services often results in cost savings compared to maintaining an in-house design team, particularly when considering the expertise and advanced tools involved.

7. Clear Communication and Customer Support

Effective communication ensures that your design requirements are understood and accurately implemented. Choose a provider that maintains open lines of contact, provides regular progress updates, and is responsive to your questions and feedback. Clear documentation, detailed revisions, and proactive support contribute to a smoother process and a final product that meets your expectations. Establishing good communication early on minimizes misunderstandings and reduces the risk of costly redesigns or delays.

8. Industry Standards, Certifications, and Compliance

Adherence to recognized industry standards such as ISO, ASME, or AWS certifications reflects a company's commitment to quality, safety, and best practices. Certifications ensure that the design services comply with international or regional standards for safety, durability, and performance. Confirm that your service provider has relevant certifications and follows strict quality control protocols. This compliance guarantees that your sheet metal products will meet regulatory requirements and industry benchmarks.

9. Innovation and Use of Modern Technologies

The sheet metal fabrication industry is continuously evolving with new materials, techniques, and design innovations. A forward-thinking service provider invests in research and development, utilizing technologies like automation, AI-driven design optimization, and advanced simulation tools. Such innovations can reduce material costs, improve structural integrity, and streamline manufacturing processes. Providers that stay current with technological advancements can offer you innovative solutions that give your products a competitive edge.

10. Post-Design Support and Value-Added Services

Beyond initial design services, consider whether the provider offers additional support such as prototyping, testing, and fabrication consulting. Post-design assistance can help identify potential manufacturing issues early, saving time and costs. Some providers also offer value-added services like rapid prototyping, design for manufacturability (DFM) analysis, and material selection guidance, which can significantly enhance your project outcomes.

Conclusion

Choosing the right sheet metal fabrication design services involves evaluating multiple factors to ensure quality, efficiency, and cost-effectiveness. Prioritize providers with extensive industry experience, comprehensive service offerings, advanced technical capabilities, and a strong commitment to quality and customer support. Whether you need sheet metal drafting services, sheet metal modeling services, or solidworks sheet metal drawing services, the right partner can transform your ideas into precise, manufacturable designs that stand the test of time.

Investing time in selecting a reliable service provider will ultimately lead to better product quality, reduced production costs, and faster time-to-market. Remember, the key to successful sheet metal fabrication lies in the foundation of excellent design—so choose wisely.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.