Laser Cutting Machine Market Analysis 2025–2032: Global Trends, Technological Shifts, and China's Strategic Position with YIHAI LASER

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

KEY MARKET INSIGHTS

The global market for laser cutting machines is growing fast. In 2025, the market size is expected to be USD 6.85 billion. By 2032, it could grow to USD 14.14 billion. This is a compound annual growth rate (CAGR) of 10.9%. This growth is driven by demand for precision, speed, and cleaner cutting.

Laser Cutter systems are used in many industries. These include automotive, aerospace, electronics, packaging, and metalworking. As more companies automate, the need for laser cutting machines grows.

YIHAI LASER, a leader in Laser Cutting Machine China, is helping meet this demand. They build machines that are fast, smart, and efficient.

Laser Cutting Machines Market Trends

1. Rise of Fiber Laser Technology

Old CO₂ lasers are being replaced by fiber lasers. These machines are faster, more efficient, and use less power. They also last longer. That makes them cheaper to use over time.

YIHAI LASER offers many fiber laser cutters. These include sheet laser cutters, tube laser cutters, and sheet & tube combo machines.

2. Smart Manufacturing

Factories now use AI and automated systems. Laser cutters are part of this change. Smart systems can cut parts with exact shapes and no mistakes.

YIHAI LASER uses Raycus or IPG lasers, plus Raytools cutting heads. These are top brands. Their machines also include Yaskawa servo motors and HIWIN rails. These parts help the machines run fast and smooth.

3. More Applications in Many Industries

Laser cutters are now used to make car parts, phone parts, aerospace parts, and even kitchen tools. This means more people need these machines.

YIHAI LASER builds different machines for these needs. They even offer laser welding and laser cleaning machines.

Laser Cutting Machines Market Growth Factors

1. High Cutting Speed and Accuracy

Laser cutters are very fast. They also make clean cuts with no rough edges. This saves time in finishing. Companies like this because it lowers labor costs.

2. Less Waste, More Savings

Laser cutters make less waste. That means companies save money. They also help reduce material loss.

3. Better Designs and Custom Orders

People want custom parts. Laser cutters can follow digital designs. This means businesses can make one part or many. It's good for small jobs and big orders too.

4. Support from Governments

In China, India, and the U.S., governments support smart factories. This helps people buy machines like laser cutters. They offer loans, tax breaks, and training programs.

Laser Cutting Machine China makers like YIHAI LASER benefit from this. It lets them grow faster.

RESTRAINING FACTORS

1. High Start-up Cost

Laser cutters are not cheap. They can cost a lot to buy and install. Small shops may not have enough money at first.

2. Need for Skilled Workers

To use a laser cutter, you need to know how it works. You also need to fix it if it breaks. Some places don't have enough trained workers.

3. Rules and Safety Standards

Laser machines must follow safety rules. This includes rules about air, heat, and light exposure. Meeting these rules adds extra cost.

Laser Cutting Machines Market Segmentation Analysis

By Technology Type Analysis

Fiber Laser Machines

These are the most used today. They are fast, reliable, and eco-friendly. YIHAI LASER is known for its fiber laser cutting machines.

CO₂ Laser Machines

These are older. They still work well for wood, plastic, and leather.

Solid-State Lasers

These use different materials. They work best for cutting metal and hard plastics.

By Function Type Analysis

Manual Machines

These need a person to move the laser. They are used for simple jobs.

Semi-Automatic Machines

These do most of the work on their own. They still need a person to watch or help.

Fully Automatic Machines

These can load, cut, and unload by themselves. They work fast and save money. YIHAI LASER offers fully automated systems with smart software.

By End-User Analysis

Automotive Industry

Car makers use laser cutters for body panels, frames, and interior parts.

Electronics

Laser cutters help make tiny parts for phones, computers, and chips.

Aerospace

Planes need strong, light parts. Laser cutters make parts with exact size and shape.

Metal Fabrication

Many shops use laser cutters to make furniture, doors, and signs.

Construction

Laser cutters make metal beams, frames, and tools for buildings.

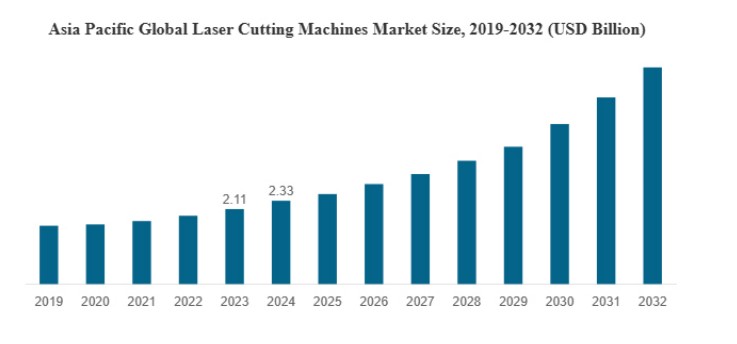

REGIONAL INSIGHTS

Asia Pacific

This region leads the market. China is the biggest player. It has many factories, cheap labor, and fast-growing demand. Most Laser Cutting Machine China brands export machines all over the world.

YIHAI LASER is based in China and ships machines to 70+ countries. They offer CE and ISO 9001 certified products.

China is also a leader in smart factory projects. They use more robots and lasers every year.

Middle East and Africa

This region is growing slower but has good potential. Countries like UAE and Saudi Arabia are building more cities and roads. They use laser cutters to make metal parts for these projects.

YIHAI LASER – CHINA'S FIBER LASER INNOVATOR

YIHAI LASER is a rising brand in the Laser Cutting Machine China space. They are based in Shandong, China. Their products include:

- Sheet Laser Cutting Machine

- Tube Laser Cutting Machine

- Sheet & Tube Laser Cutting Machine

- Laser Welding Machine

- Laser Cleaning Machine

- Bending Machine

- Shearing Machine

Their machines use Raycus or IPG laser sources and Raytools heads. They also use Yaskawa motors and HIWIN rails for strong and smooth movement.

Their machines are sold with training, tech support, and custom service. They focus on making machines that are easy to use, long-lasting, and safe.

Use Case: Calculating Laser Cut Part Weight

To know how much a cut metal part weighs, use this formula:

Weight (grams) = Area (mm²) × Thickness (mm) × 0.00785

Let's say your part is shaped like the letter "Q" and has:

- Area = 5000 mm²

- Thickness = 3 mm

- Material = Steel (density = 7.85 g/cm³)

- Weight = 5000 × 3 × 0.00785 = 117.75 grams

Use this method to estimate shipping costs, inventory, or production time.

FUTURE OUTLOOK

By 2032, more factories will use laser cutters. This means:

- Faster delivery

- Better designs

- Lower costs

- Less material waste

- Laser Cutting Machine China brands like YIHAI LASER will grow. They make machines that are:

- Affordable

- Reliable

- Custom-built

- Energy-efficient

They also offer welding, cleaning, and bending machines, making them a one-stop shop for metal processing.

MARKET SNAPSHOT TABLE

| Metric | Details |

| Market Name | Laser Cutting Machine Market |

| Base Year | 2024 |

| Forecast Period | 2025 – 2032 |

| Market Size (2025) | USD 6.85 Billion |

| Projected Market Size (2032) | USD 14.14 Billion |

| CAGR (2025–2032) | 10.9% |

| Dominant Technology | Fiber Laser |

| Leading Region | Asia Pacific |

| Top Country | China |

| Key End-Use Sectors | Automotive, Electronics, Aerospace, Metal Fabrication, Construction |

| Notable Players | YIHAI LASER |

| Primary Applications | Sheet Cutting, Tube Cutting, Welding, Cleaning, Bending |

CONCLUSION

The world needs faster, smarter, and cleaner ways to cut metal. That's why the laser cutting machine market is growing.

YIHAI LASER is ready for this future. Their fiber laser machines, affordable pricing, and global support make them a key player.

If your business needs a laser cutter that's easy to use, reliable, and backed by experts, then YIHAI LASER is the name to trust.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.