Lockout Tagout: Safeguarding Workplaces with Reliable Safety Devices

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In workplaces where machinery and equipment are regularly serviced or maintained, the risk of accidental energy release poses a serious threat to worker safety. To mitigate this risk, the Lockout Tagout system is a critical safety procedure that ensures dangerous machines are properly shut off and not restarted until maintenance is complete. With the help of reliable safety devices, LOTO not only prevents accidents but also ensures compliance with safety regulations such as those outlined by OSHA (Occupational Safety and Health Administration).

What is Lockout Tagout (LOTO)?

If you clearly understand what Lockout Tagout is and how to control hazardous energy, you can significantly reduce and often avoid all types of accidents that may result from LOTO negligence.

Lockout Tagout refers to specific practices and procedures designed to safeguard employees from the unexpected energization or startup of machinery and the release of hazardous energy during maintenance or servicing activities. This system involves two key elements:

• Lockout: Physically locking the energy-isolating device using specialized lockout devices and padlocks.

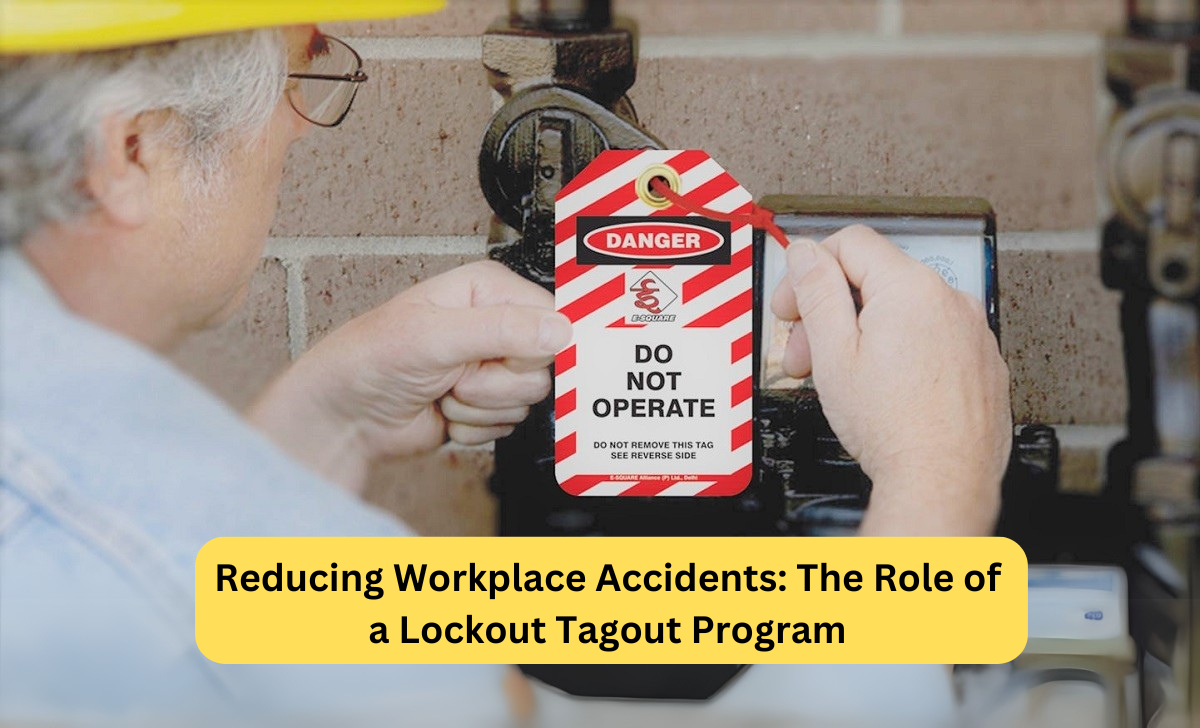

• Tagout: Attaching warning tags to indicate that the equipment is under maintenance and must not be operated.

Together, these measures prevent unauthorized operation and ensure that workers performing maintenance are protected from potential hazards.

The Importance of Reliable Safety Devices

The effectiveness of any LOTO program hinges on the quality and reliability of the safety devices used. These devices must be durable, easy to use, and capable of withstanding the environmental conditions of the workplace. Using substandard or makeshift tools can lead to lockout failure, equipment damage, or, worse, injuries and fatalities.

Reliable lockout tagout devices include:

• Lockout Padlocks: Specifically designed with non-conductive materials, unique keying systems, and tamper-resistant features.

• Safety Tags: Brightly colored tags that convey critical information about who locked the equipment and why.

• Lockout Hasps: Allow multiple workers to apply their locks on a single isolation point, ensuring collaborative maintenance safety.

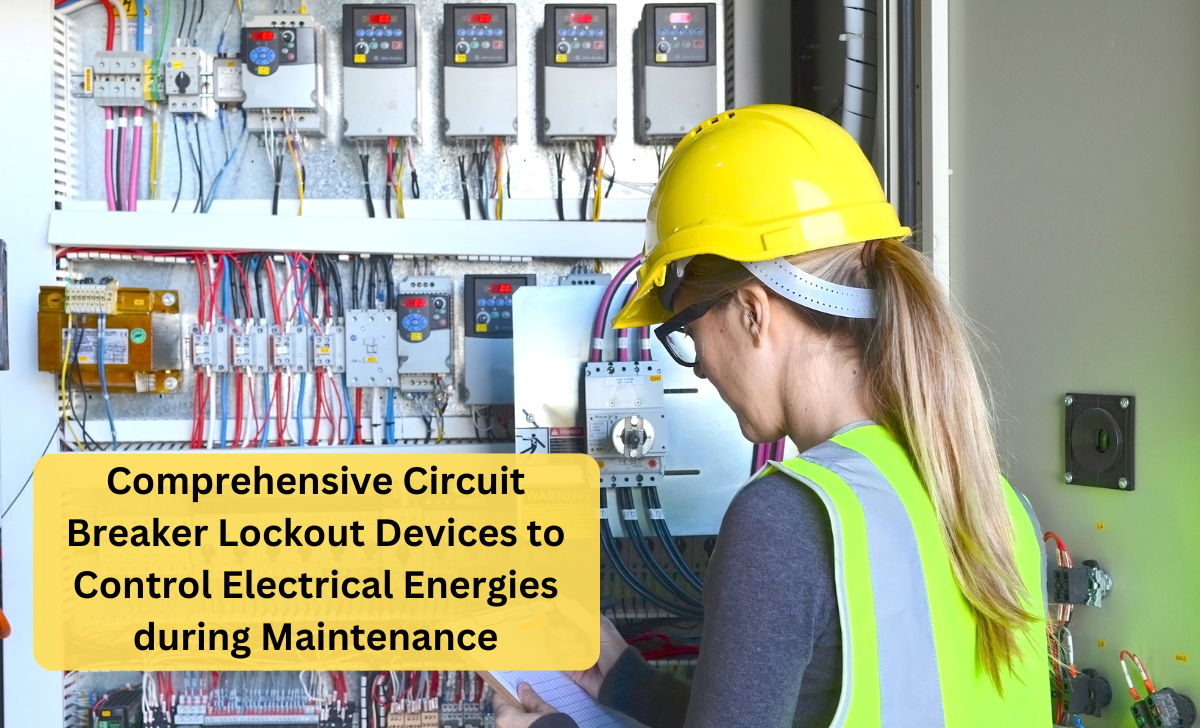

• Circuit Breaker Lockouts: Prevent breakers from being switched on during electrical work.

• Valve Lockouts: Secure ball, gate, butterfly, and other valve types in the off position.

• Lockout Stations: Centralized boards or kits to store and organize LOTO devices for quick access.

Each device is tailored to isolate specific types of energy sources - mechanical, hydraulic, electrical, thermal, or pneumatic - and must be chosen based on the equipment and energy type involved.

Industries That Benefit from LOTO Implementation

LOTO procedures are applicable across a wide range of industries, including manufacturing, oil and gas, utilities, construction, chemical processing, and food production. In any environment where moving parts, pressurized systems, or high voltage are present, LOTO is essential to minimize workplace risks.

For instance:

• In manufacturing, machinery often requires regular maintenance. Lockout devices ensure machines cannot be restarted accidentally.

• In the energy sector, isolation of high-voltage systems using circuit breaker lockouts prevents fatal shocks.

• In water treatment plants, valve lockouts ensure workers aren’t exposed to pressurized chemicals or gases.

Compliance and Legal Requirements

According to OSHA standard 29 CFR 1910.147, employers are required to develop and implement LOTO programs that include training, periodic inspections, and proper use of energy control devices. Non-compliance can lead to severe penalties, legal action, and irreversible workplace accidents.

Investing in certified and durable lockout tagout devices is not just a matter of regulatory compliance - it reflects an organization’s commitment to worker safety and operational excellence.

Training: A Critical Component

While having the right devices is crucial, employee training is equally important. Workers must understand how to identify energy sources, apply the correct lockout devices, attach proper tags, and follow the procedure for verifying energy isolation. Regular training ensures consistency and reinforces a culture of safety.

Conclusion

Lockout Tagout is more than just a procedural checklist - it's a life-saving safety system that protects employees from hazardous energy during maintenance and servicing activities. By using high-quality, purpose-built safety devices and ensuring comprehensive training, organizations can effectively prevent accidents, protect their workforce, and remain compliant with safety standards.

A strong LOTO program reflects a proactive approach to workplace safety - one that values human life over convenience and sets the foundation for a safer, more efficient work environment.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.