Manufacturing Execution Systems' (MES) Function in Contemporary Industry

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Efficiency and flexibility are critical in the quickly changing industrial world of today. Businesses work hard to satisfy the growing demand for premium goods while preserving sustainability and cost-effectiveness. The Manufacturing Execution Systems (MES), a crucial element in the digitization of industrial processes, is a major enabler in this shift. MES systems provide real-time insights and control, bridging the gap between shop-floor operations and enterprise-level planning.

A Manufacturing Execution System: What Is It?

A MES system is a piece of software made to track, monitor, and improve shop floor production operations. MES software serves as a link between the operational layer and Enterprise Resource Planning (ERP) systems, ensuring that production processes are in perfect harmony with business objectives. It records information.

By implementing an MES, manufacturers can enhance visibility into their processes, reduce downtime, and improve overall efficiency. MES solutions are particularly critical for industries with complex production environments, such as automotive, electronics, pharmaceuticals, and food and beverage.

Essential Elements of MES Software

Real-Time Data Collection: MES software gathers and analyzes data instantly, giving producers useful information about production parameters including yield, cycle time, and equipment usage.

Production Scheduling: Advanced MES solutions provide dynamic scheduling features that allow manufacturers to modify production schedules in response to priorities and real-time restrictions.

Quality Management: By integrating quality control procedures, MES systems guarantee that goods fulfill legal and predetermined criteria.

Inventory management: MES software reduces waste and maximizes inventory levels by monitoring raw materials and completed goods.

End-to-end traceability, which MES solutions offer, is essential for sectors where product recalls and compliance are major issues.

Advantages of MES Solution Implementation

MES system adoption has several advantages that support operational excellence, including:

Increased Productivity: Real-time monitoring and analytics lower downtime and increase throughput by enabling prompt bottleneck detection and resolution.

Better Quality Control: MES software guarantees constant product quality by incorporating quality inspections straight into the production process.

Cost Savings: Over time, considerable cost reductions are achieved through improved workflows and less waste.

Regulatory Compliance: By preserving accurate records and traceability, MES solutions assist firms in adhering to industry standards and laws.

Data-Driven Decision-Making: Manufacturers can improve efficiency and innovation by making well-informed decisions based on historical and real-time data.

The Operation of MES Systems in a Smart Factory

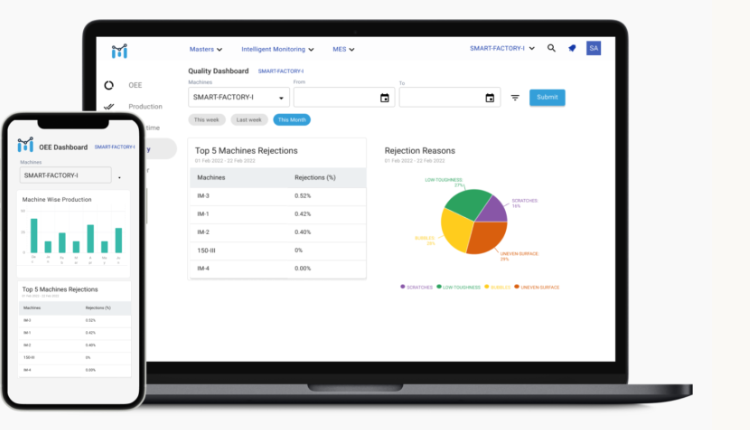

MES systems are essential to the idea of the smart factory in the context of Industry 4.0. MES software makes it easier for machines and systems to communicate with one another by integrating with sensors, IoT devices, and other cutting-edge technology. Continuous improvement, adaptive scheduling, and predictive maintenance are made possible by this networked ecosystem.

An MES system in a smart factory, for instance, can:

Keep an eye on machine performance and anticipate possible issues before they arise.

Adapt production plans automatically in response to changes in demand in real time.

Use mobile apps and user-friendly dashboards to give operators relevant insights.

Selecting the Appropriate MES Firm

The effective deployment of a MES solution depends on choosing the appropriate MES provider. Manufacturers ought to take into account elements like the business's experience in the field,

MES Software's Future

MES Software are anticipated to integrate cutting-edge features like artificial intelligence (AI), machine learning (ML), and augmented reality (AR) as manufacturing continues to develop. These innovations will improve MES solutions' capacity to forecast patterns, streamline workflows, and give operators engaging training.

Additionally, cloud-based MES platforms are becoming more popular because to their increased scalability and flexibility. Manufacturers may save upfront expenses, guarantee data security, and provide remote access to vital production data by utilizing cloud technologies.

In conclusion

More than just a tool, the Manufacturing Execution System is a revolutionary force that propels productivity, quality, and creativity in the manufacturing industry. Businesses can confidently and nimbly handle the problems of contemporary industry by implementing MES systems. Investing in a strong MES system may help you reach new heights of efficiency and competitiveness, regardless of your size—from tiny manufacturers to multinational corporations.

MES businesses are leading the way in the industry's adoption of digital transformation, offering innovative solutions that enable manufacturers. Your factory information system can become a strategic asset with the correct MES software, opening the door to long-term success and growth.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.